Manufacturing method for elastic composite material

A technology of elastic composite material and manufacturing method, which is applied in tire parts, transportation and packaging, special tires, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

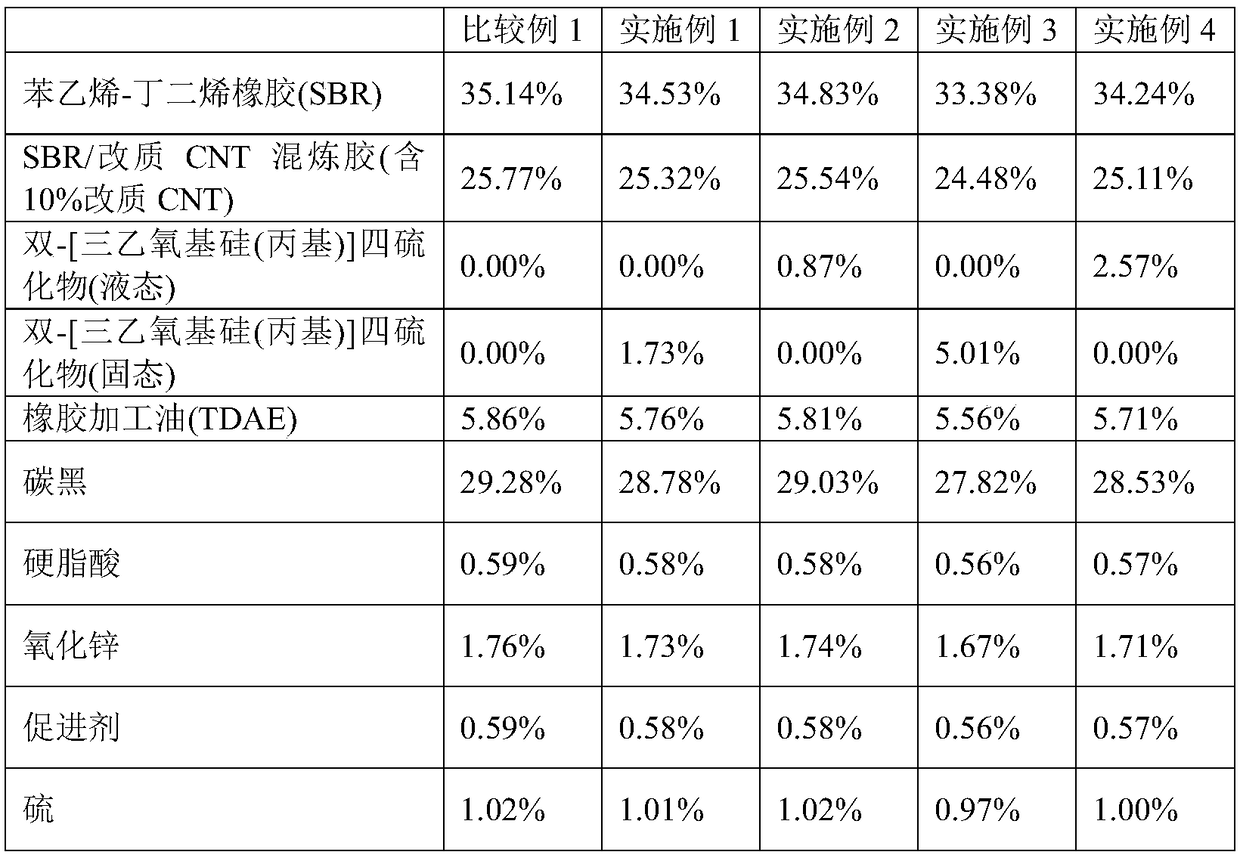

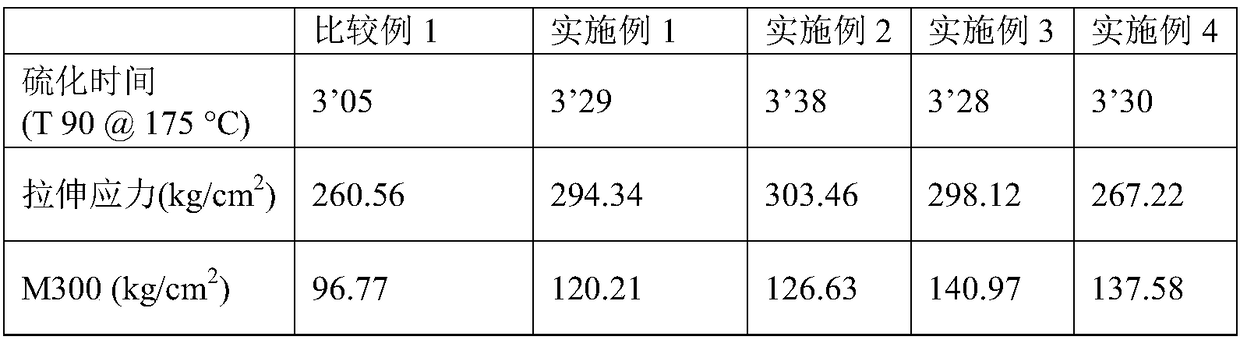

[0038] Next, the elastic composite materials of Comparative Example 1, Example 1, Example 2, Example 3, and Example 4 were manufactured according to the different formulations in Table 1 for subsequent physical tests. The test includes tensile stress, M300, and loss factor tanδ, and the results are shown in Table 2 below.

[0039] Table 1: Units (weight percent)

[0040]

[0041] Table 2

[0042]

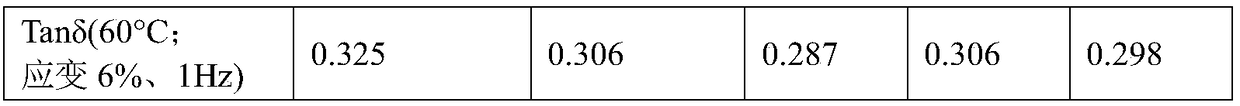

[0043]

[0044] The vulcanization time (T 90@175°C) in Table 2 is based on ASTM D2084 and ISO3417 international standards, and the vulcanization degree and vulcanization time of a sulfur-containing rubber composite at high temperature (150°C-195°C) are analyzed by a rheometer. The relationship curve, the present invention is set to analyze at 175 ℃; M300 (kg / cm 2 ) represents the stress value at 300% stretching, the higher the value, the more rigid; the lower the value of tanδ, the smaller the rolling resistance. Can find through above table 2 result: when adding this bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com