A kind of anti-scaling and anti-corrosion functional coating and its preparation method and application method

A technology of functional coatings and functional fillers, used in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve problems such as accelerated corrosion and achieve the effect of preventing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

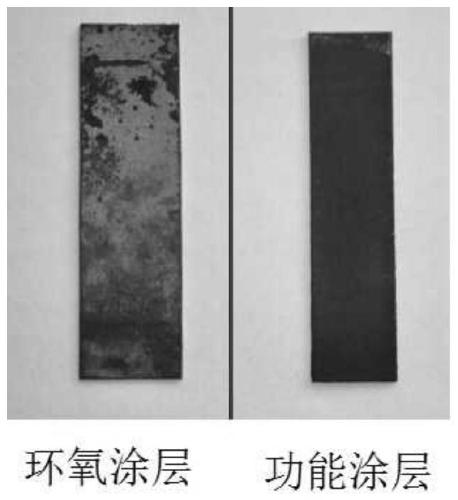

Problems solved by technology

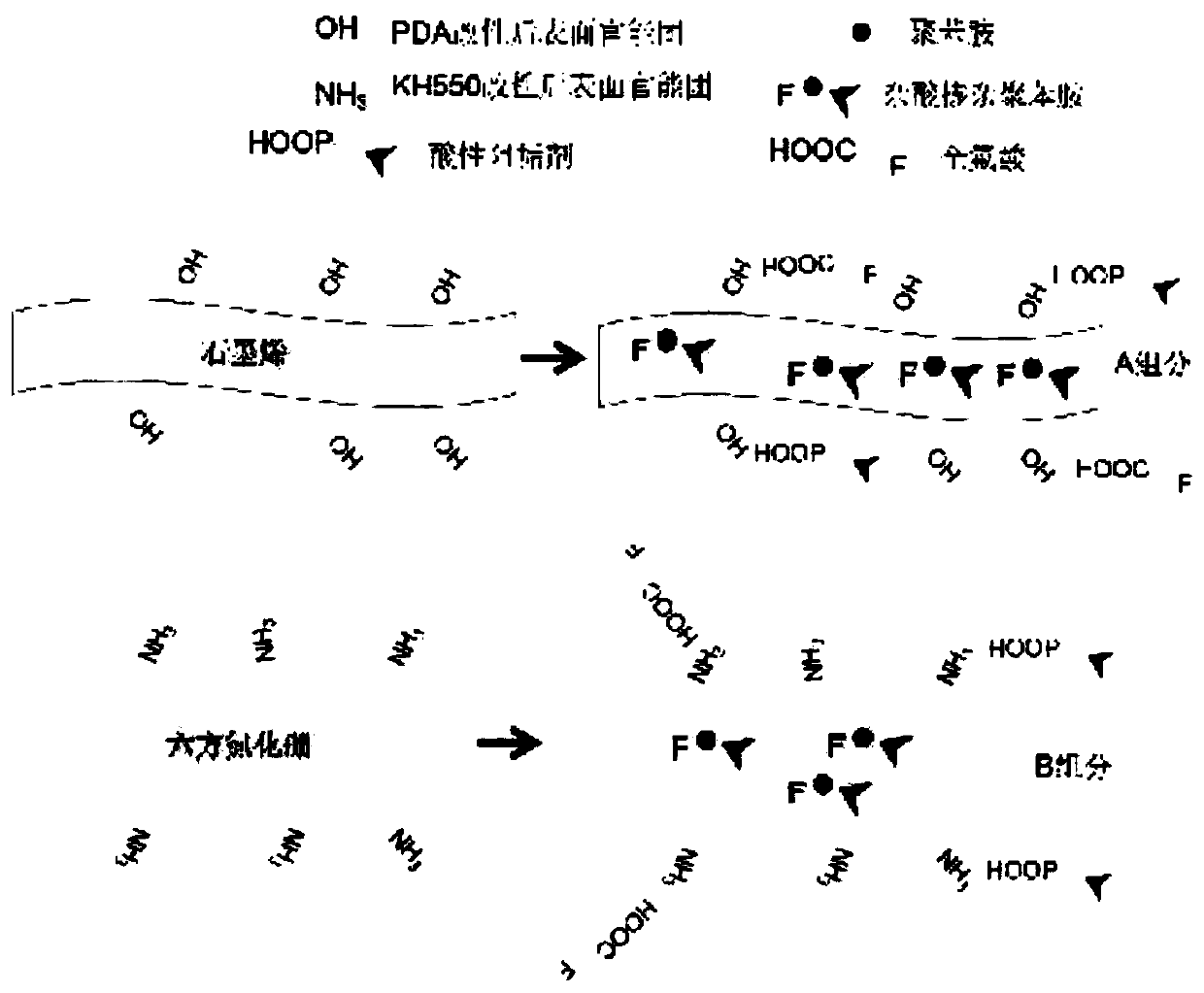

Method used

Image

Examples

Embodiment 1

[0057] (1) Metal surface pretreatment:

[0058] Use 400-mesh sandpaper to quickly polish the metal surface, then put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface.

[0059] (2) Preparation of paint:

[0060] Take 2 parts of Tris-HCl (10mM, pH=8.5) buffer solution in a beaker and add 0.1 part of graphene oxide, add 0.05 part of dopamine after ultrasonic dispersion for 10 minutes, take 0.1 part of HEDP and 1 part of perfluorooctanoic acid after magnetic stirring at room temperature for 10 hours Add 0.05 parts of aniline dropwise into the solution, stir for 30 min until the aniline is completely dissolved, add 0.2 parts of ammonium persulfate and stir for 6 hours to end, filter and dry to obtain A functional filler.

[0061]Add 0.5 parts of hexagonal boron nitride to 15 parts of water and 10 parts of absolute ethanol and sonicate for 30 min, then add 0.1 part of KH550 and stir for 1 h. After complete reaction, he...

Embodiment 2

[0069] (1) Metal surface pretreatment:

[0070] Use 400-mesh sandpaper to quickly polish the metal surface, then put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface.

[0071] (2) Preparation of paint:

[0072] Take 5 parts of Tris-HCl (10mM, pH=8.5) buffer solution in a beaker and add 0.05 parts of graphene oxide, add 0.05 parts of dopamine after ultrasonic dispersion for 10 minutes, take 0.001 parts of ATMP and 0.001 parts of perfluorooctanoic acid after magnetic stirring at room temperature for 10 hours Add 0.01 part of amino-terminated aniline dropwise into the solution, stir for 30 min until the amino-terminated aniline is completely dissolved, add 0.1 part of ammonium persulfate and stir for 4 hours to end, filter and dry to obtain component A, and set aside.

[0073] Add 0.1 part of hexagonal boron nitride to 15 parts of water and 5 parts of absolute ethanol and sonicate for 30 min, then add 0.1 part of KH5...

Embodiment 3

[0079] (1) Metal surface pretreatment:

[0080] Use 400-mesh sandpaper to quickly polish the metal surface, then put it into an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface.

[0081] (2) Preparation of paint:

[0082] Take 1 part of Tris-HCl (10mM, pH=8.5) buffer solution in a beaker and add 0.1 part of graphene oxide, add 0.5 part of dopamine after ultrasonic dispersion for 10 minutes, take 0.1 part of DTPMPA and 0.1 part of perfluorooctanoic acid after magnetic stirring at room temperature for 10 hours Add 0.1 part of aniline dropwise into the solution, stir for 30 minutes until the aniline is completely dissolved, add 0.2 part of ammonium persulfate and stir for 10 hours to complete, filter and dry to obtain component A, and set aside.

[0083] Add 5 parts of hexagonal boron nitride to 20 parts of water and 10 parts of absolute ethanol and sonicate for 10 min, add 5 parts of KH570 and stir for 1 h. After the complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com