Bent slot adjusting sliding frame

A sliding frame and curved groove technology, applied in the direction of machine/support, supporting machine, mechanical equipment, etc., can solve the problems of difficult maintenance, uneven thickness and uneven force in the later stage, and achieve enhanced stability and ease of use. The effect of counteracting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

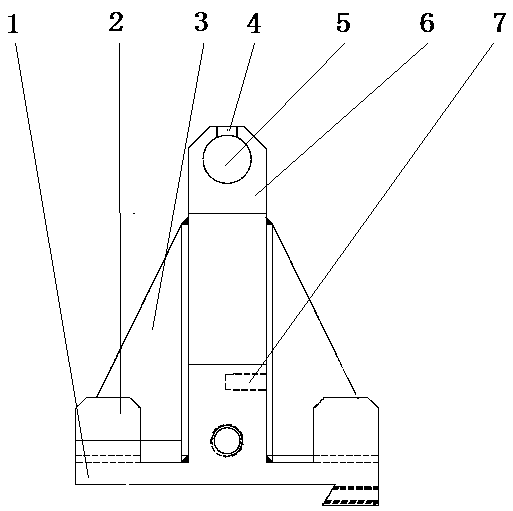

[0016] like figure 1 As shown, a curved groove adjustment carriage includes a base 1, a sliding beam 2, a reinforcing rib 3, a sliding groove 4, a positioning hole 5, a buffer beam 6 and an adjusting rod 7, and the curved groove adjusting carriage is a "mountain" as a whole. Font-shaped structure, the bottom end of the curved groove adjustment carriage is the base 1, and the plane where the base 1 is located is provided with a fixed base on one side of the bottom end, and the fixed base is tangent to one side edge of the base 1, and the base 1. A buffer beam 6 is provided at the straight line where the center line is located. The buffer beam 6 protrudes above the base 1 and is respectively connected with the shorter two sides of the base 1 through the sliding beam 2.

[0017] Between the sliding beam 2 and the buffer beam 6 is reinforced by the reinforcing rib 3, a buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com