A low-voltage withdrawable switchgear push interlock mechanism

A low-voltage withdrawable, interlocking mechanism technology, applied in the direction of pull-out switchgear, switchgear, electrical components, etc., can solve the problems of affecting the normal power supply use of the switchgear, prone to breakage, large temperature impact, etc., to avoid breakage The effect of failure, easy operation and reduction of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

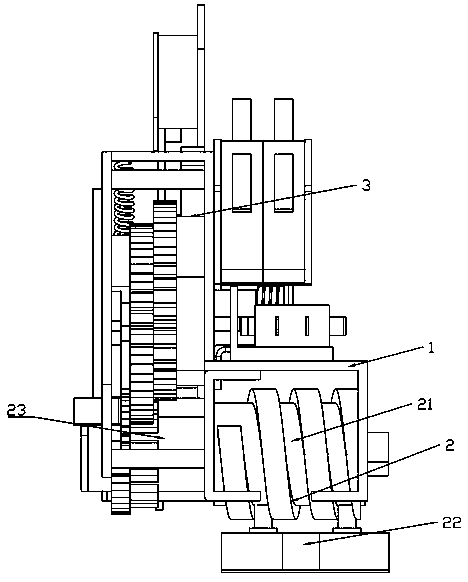

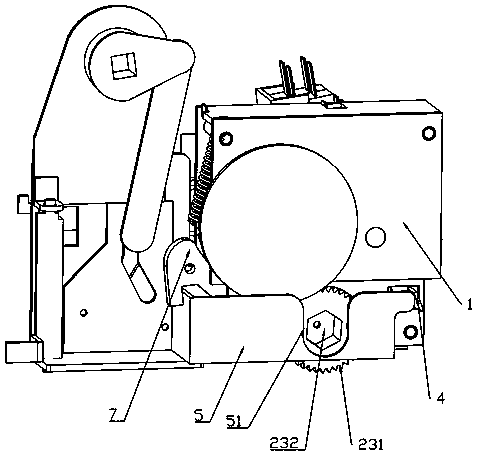

[0026] Such as figure 1 As shown, a low-voltage withdrawable switchgear push interlock mechanism includes a mounting bracket 1, a pushing mechanism 2, and a position positioning mechanism 3; the mounting bracket 1 is fastened together by bolts from a front bracket, a middle bracket, and a rear bracket. , to facilitate product assembly.

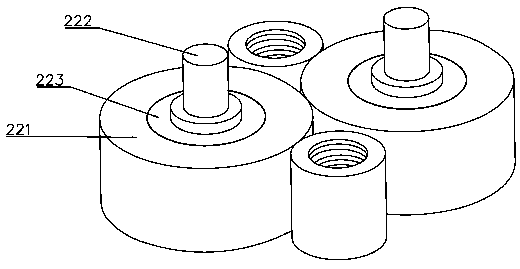

[0027] Such as Figure 1-2 As shown, the propulsion mechanism 2 is installed on the installation bracket 1, and is used to push the drawer to move in the cabinet. The screw rod 21 is fitted with a roller bearing locator 22 that pushes the drawer to move back and forth.

[0028] Wherein, the driving screw 21 and the roller bearing positioning member 22 are both made of iron material, so that they are less affected by the ambient temperature, the structure is more stable, and the occurrence of fracture failures is effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com