Hoist hopper structure for industrial construction engineering

A technology of industrial buildings and hoists, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unable to manually adjust the balance, unable to perform dehydration and filtration, and not having the ability to move directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

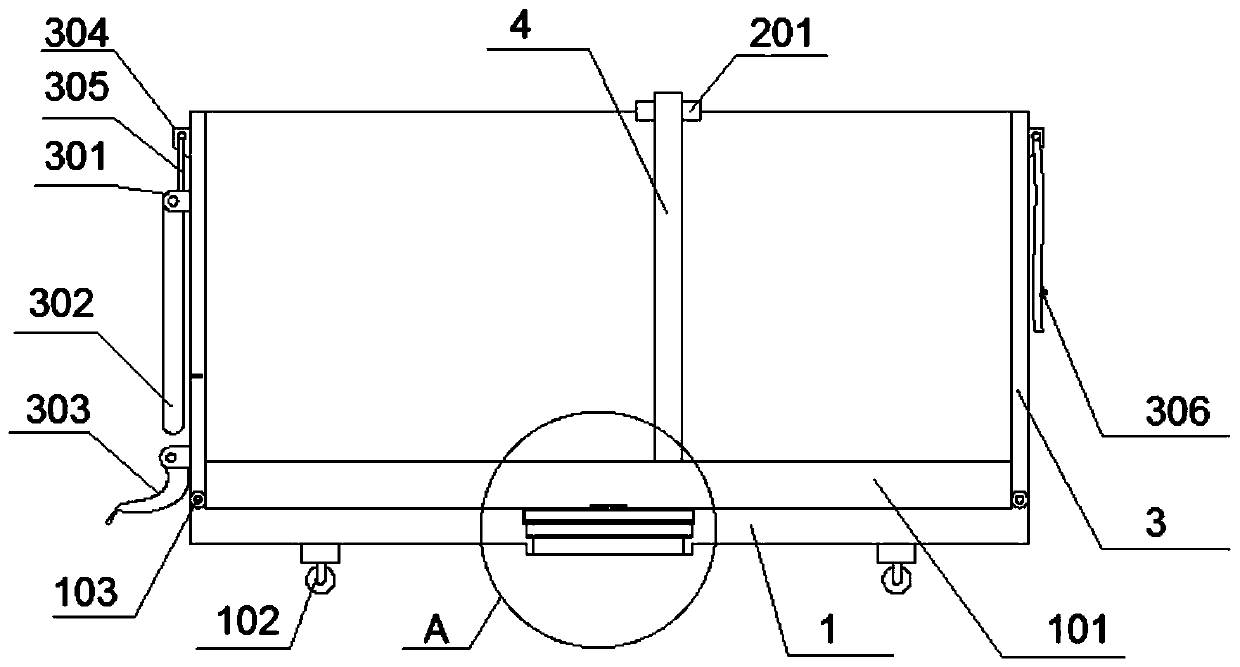

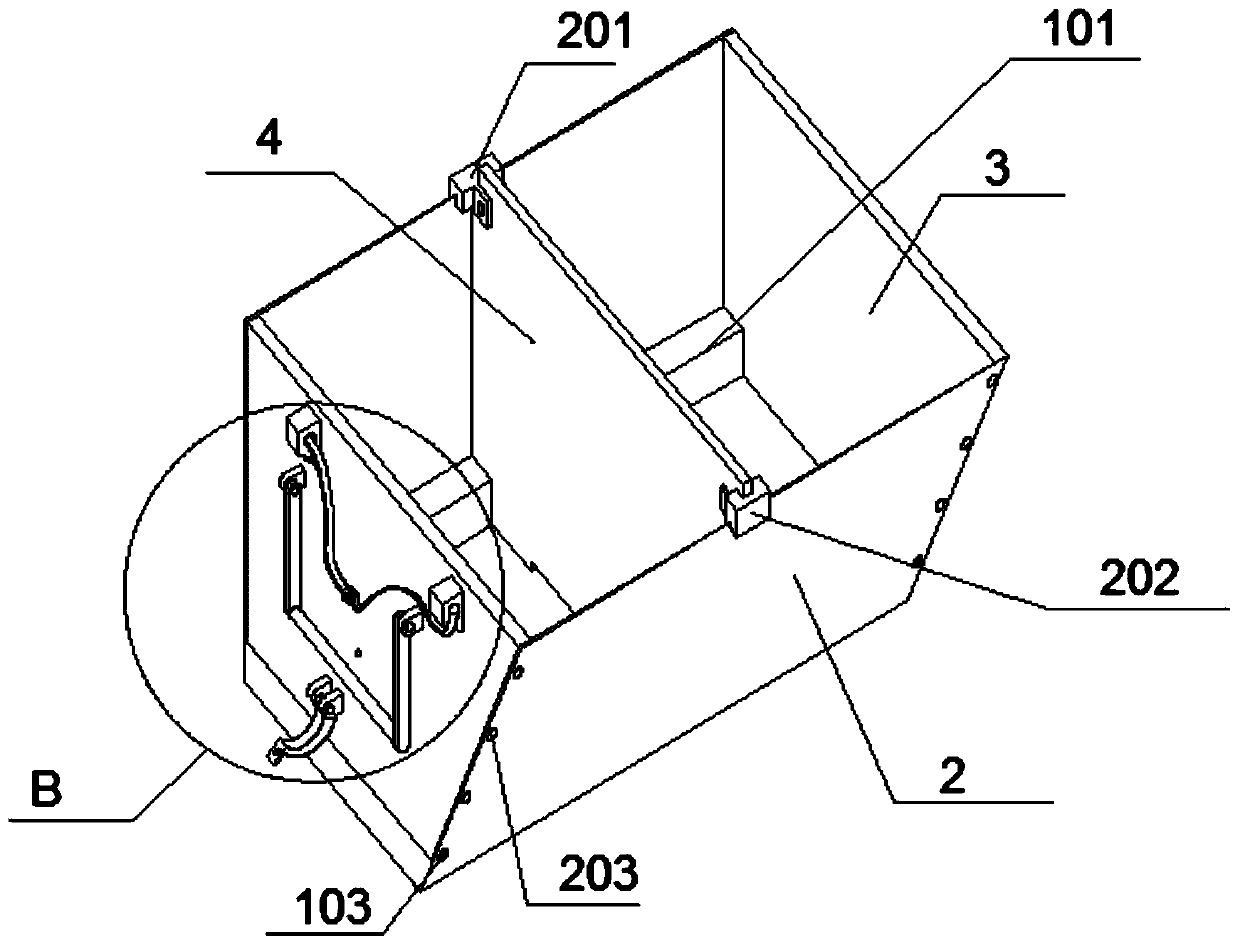

[0038] as attached figure 1 to attach Figure 8 Shown:

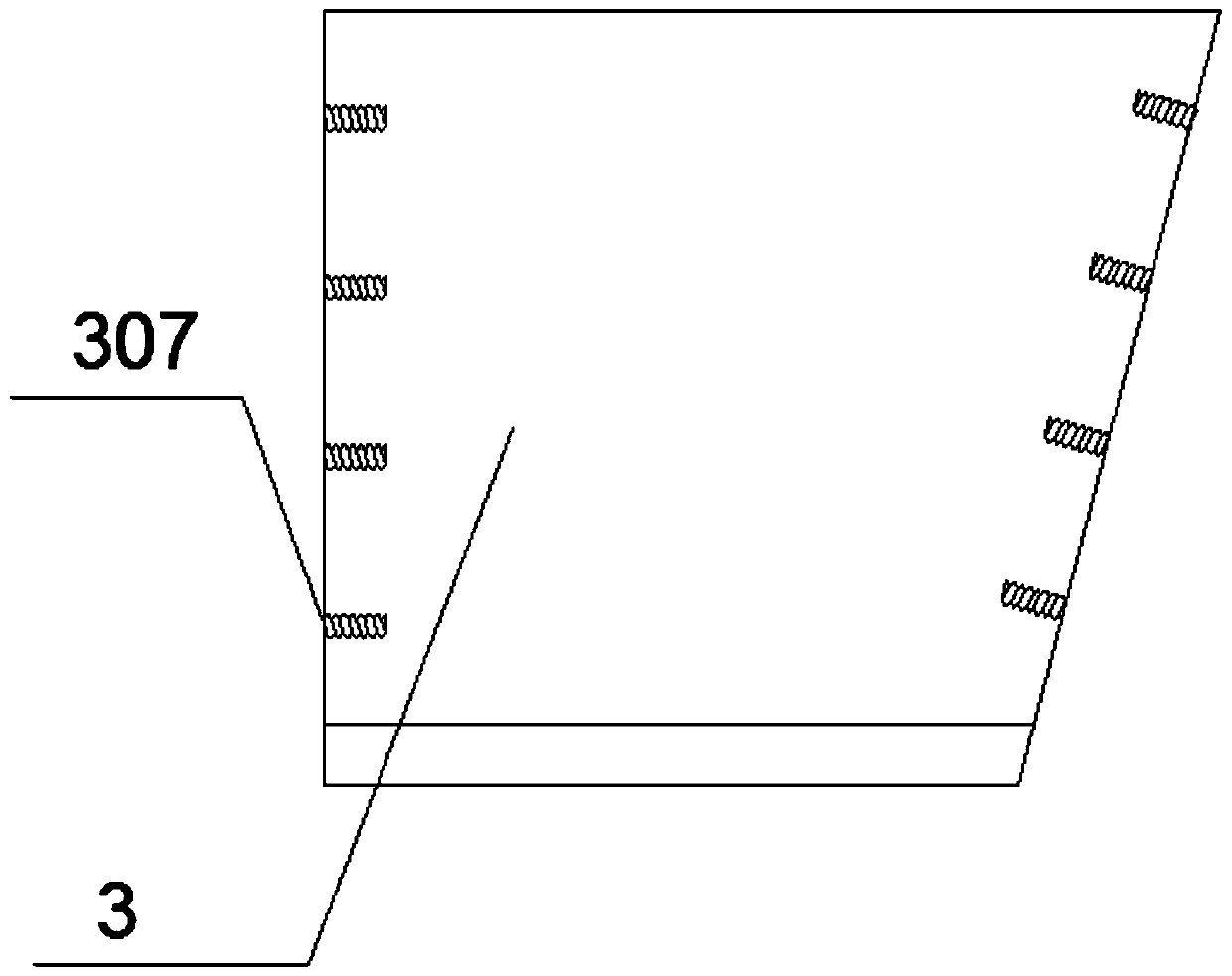

[0039]The invention provides a hoist hopper structure for industrial construction engineering, comprising a base 1, an auxiliary slider 101, a universal wheel 102, a rotating shaft A103, a water outlet 104, a filter A105, a filter B106, a leak-proof plug 107, and an anti-leakage plug 107. Drain plug handle 10701, main baffle 2, straight groove slider 201, chute slider 202, baffle through hole 203, side baffle 3, rotating shaft B301, pull rod 302, pull rod lock 303, pull rod lock through hole 30301, Sling buckle 304, sling 305, sling hook 306, screw hole 307 and partition 4; the front and rear sides of the top of the base 1 are integrally provided with the main baffle 2, and there are multiple groups of baffles on both sides of the main baffle 2 Plate through holes 203; two sets of rotating shafts A103 are integrally arranged on the top of both sides of the base 1, and two sets of side baffles 3 are arranged on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com