Continuous surface processing device for glass manufacturing

A surface processing and glass manufacturing technology, which is applied in the field of continuous surface processing devices, can solve problems such as the lifting of polishing sheets, and achieve the effects of preventing up and down fluctuations, facilitating installation, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

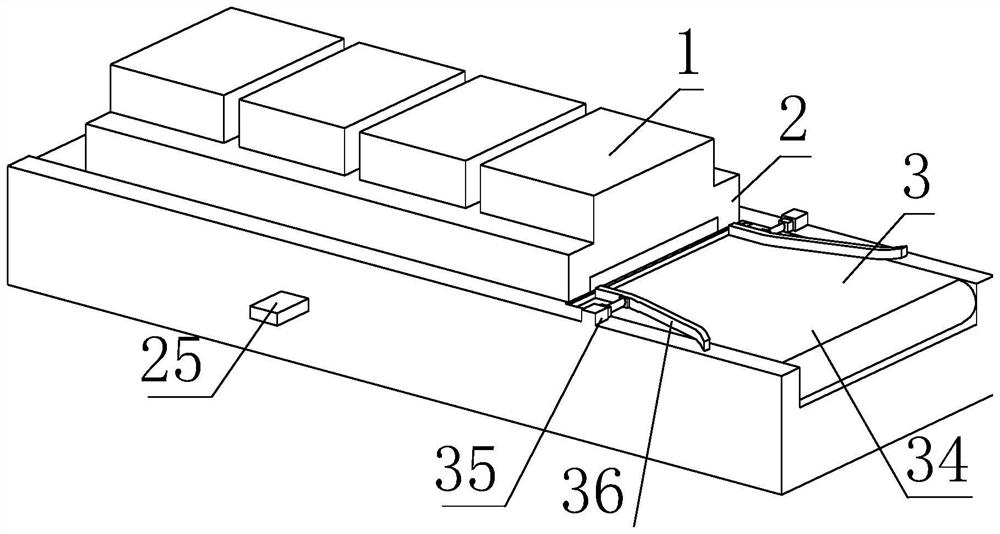

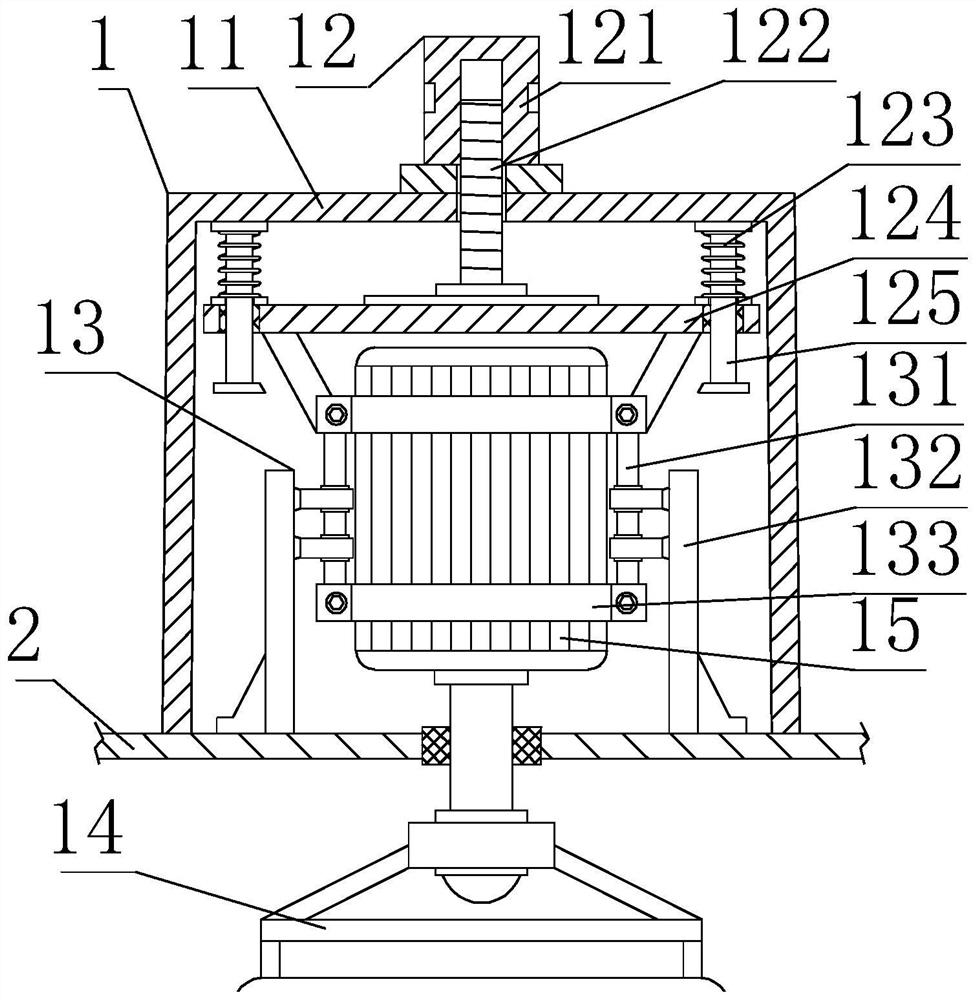

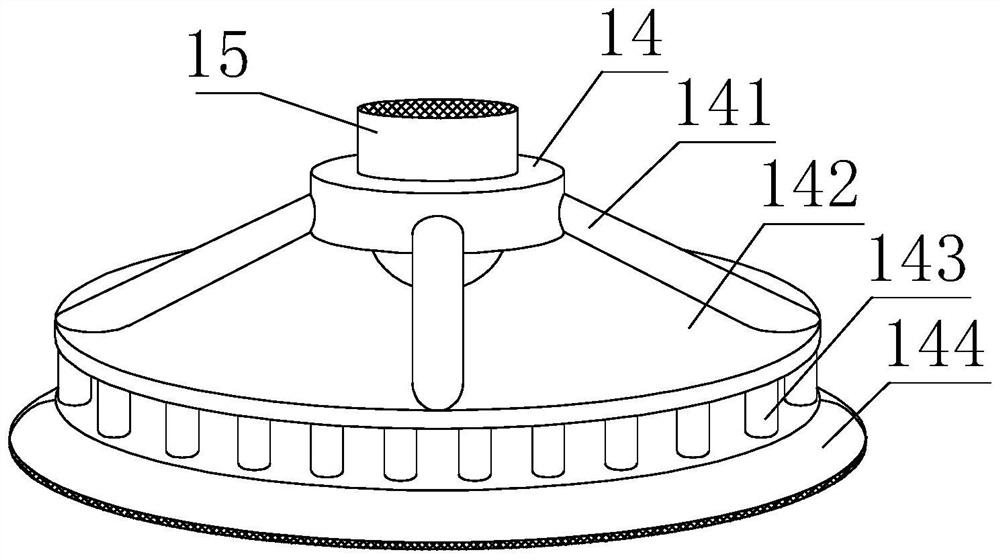

[0041] like Figure 1-8 As shown, the present invention provides a continuous surface processing device for glass manufacturing, comprising a surface processing device 1, a water pipe support 2 is fixedly installed at the bottom of the surface processing device 1, and a conveying device 3 is fixedly installed at the bottom of the water pipe support 2 , the surface processing device 1 includes a surface processing device box 11, the lower surface of the surface processing device box 11 is fixedly installed with the top of the water pipe support 2, and the top of the inner cavity of the surface processing device box 11 is provided with a lifting structure 12. The bottom of the inner cavity of the device box 11 is fixedly installed with the lifting frame 13, the middle of the lifting frame 13 is fixedly installed with the motor 15, and the bottom of the motor 15 is fixedly installed with the grinding structure 14. The transmission device 3 includes a transmission device bracket 32...

Embodiment 2

[0044] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the lifting structure 12 includes a threaded sleeve 121, and the bottom of the threaded sleeve 121 is rotatably connected to the upper surface of the surface processing device case 11, and the threaded sleeve 121 is rotatably connected. The inner cavity of 121 is threadedly connected with a threaded rod 122, and the bottom of the threaded rod 122 is rotatably connected with a fixed plate 124. There is a spring 123 , the top of the limit guide post 125 is fixedly installed with the top of the inner cavity of the surface processing device case 11 , and the outer wall of the threaded rod 122 is inserted into the top of the inner wall of the surface processing device case 11 .

[0045] The lift frame 13 includes a fixed card plate 133 , the inner wall of the fixed card plate 133 is fixedly installed with the outer wall of the motor 15 , the number of the...

Embodiment 3

[0050] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the water pipe support 2 includes a support 21, the bottom of the support 21 is fixedly installed with the upper surface of the conveying device 3, and the inner wall of the support 21 is fixedly installed with The spray pipe 23, the bottom of the spray pipe 23 is fixedly installed with a secondary water distribution pipe 22, the bottom of the secondary water distribution pipe 22 is fixedly connected with a water distribution pipe 24, and the right end of the water distribution pipe 24 is fixedly installed with the bottom of the spray pipe 23, the water distribution pipe 24 A main water pipe 26 is fixedly connected to the bottom of the left end, and a water inlet 25 is fixedly connected to the left side of the main water pipe 26 .

[0051] The spray pipe 23 includes a spray pipe water inlet 237, the bottom of the spray pipe water inlet 237 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com