Big presser foot component structure of placket machine

A technology with a component structure and a large presser foot, applied in the direction of cloth press mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of high cost and complex structure, and achieve the effect of simple structure, precise and reliable control, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the traditional structure, the two presser arms of the presser foot part of the placket machine are fastened together by fixing screws, and the two cannot move relatively laterally, so the distance between the left presser foot and the right presser foot cannot be adjusted.

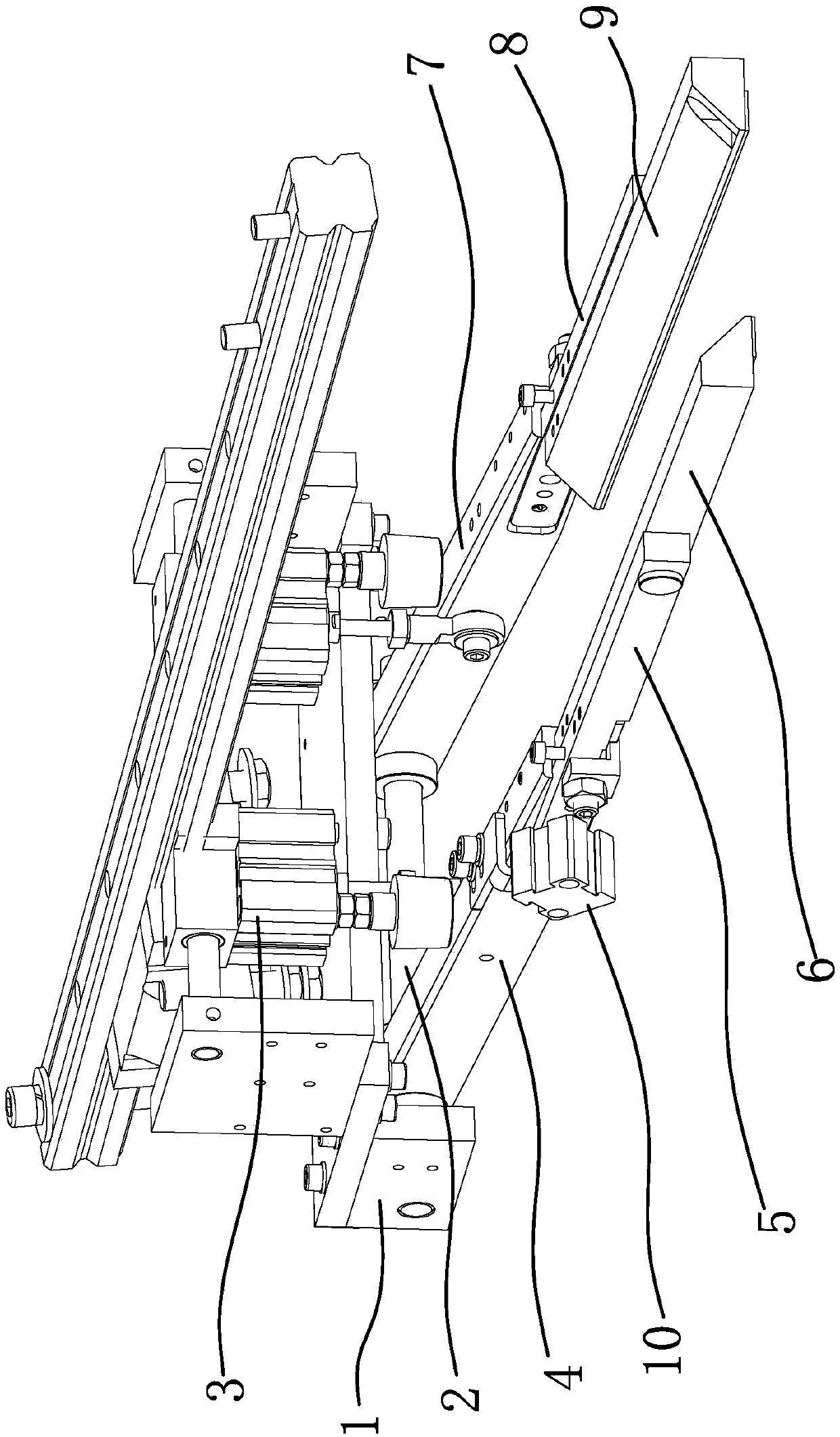

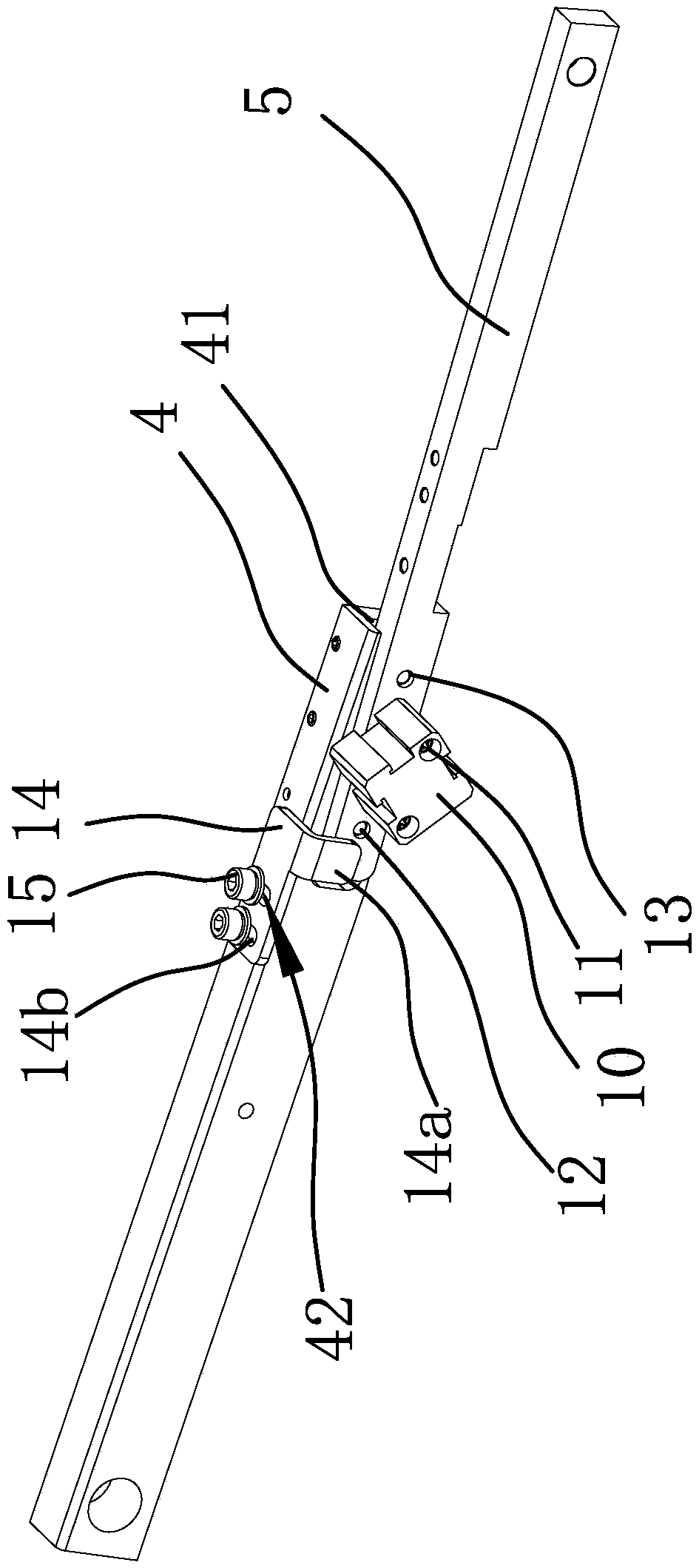

[0035] such as 1 and figure 2 As shown, the fly machine includes a mounting frame 1, and the mounting frame 1 is provided with a hinged shaft 2. The large presser foot assembly structure of the fly machine includes a left large presser arm 4 and a right large presser arm 7 arranged side by side at intervals. One end of the left large presser arm 4 and the right large presser arm 7 is all connected on the hinge shaft 2, and the installation frame 1 is also provided with a hinge that enables the other ends of the left large presser arm 4 and the right large presser arm 7 to be hinged. Shaft 2 swings down the downward pressure cylinder 3; the end of the left large presser arm 4 is connected with t...

Embodiment 2

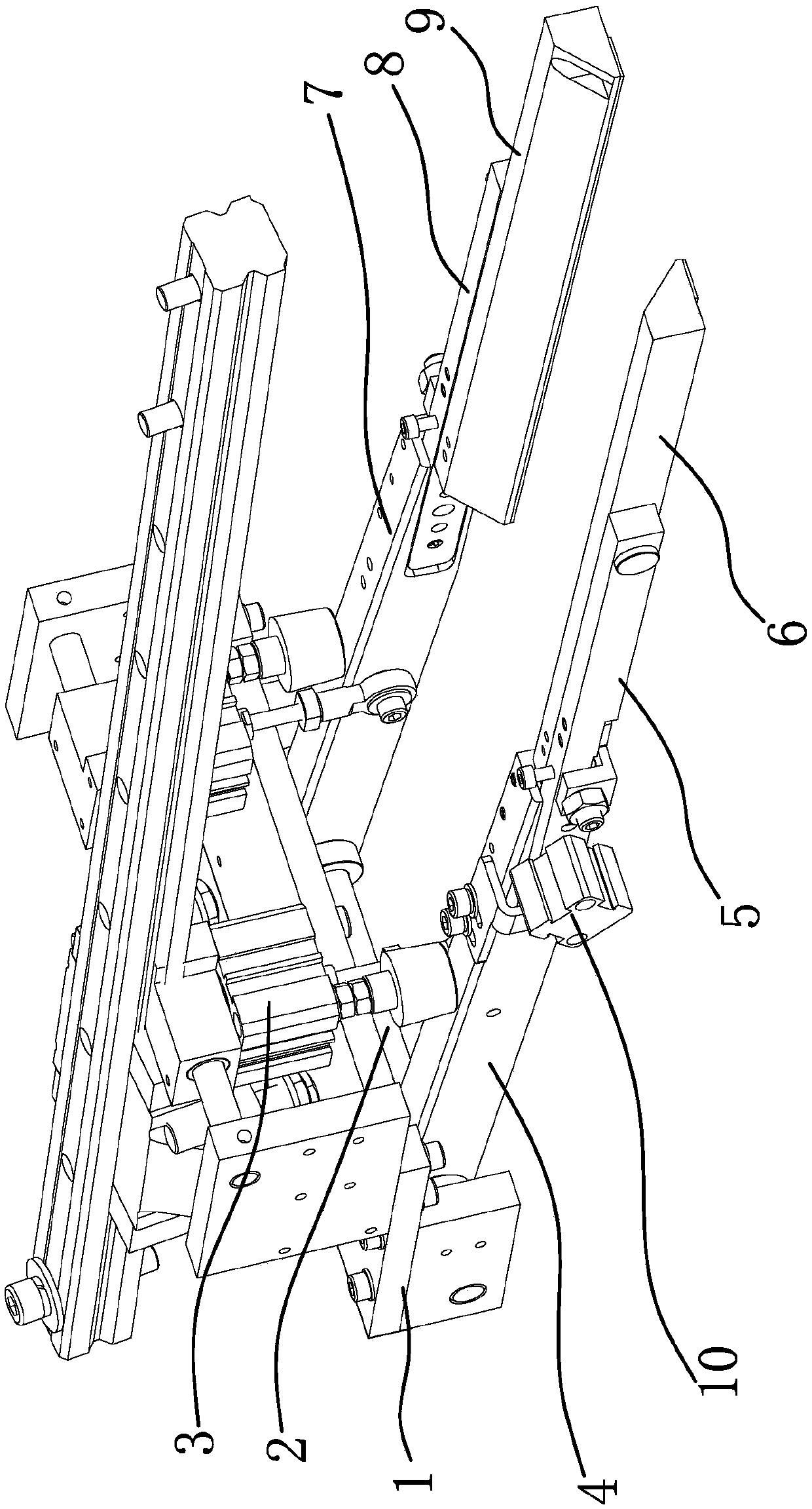

[0042] Such as image 3 and Figure 4 As shown, this embodiment is roughly the same as Embodiment 1, the difference is that in this embodiment, the drive cylinder 10 is fixed on the outer surface of the end of the left large presser arm 4 close to the left small presser arm 5, and the drive cylinder The piston rod end of 10 is fixedly connected with a connecting shaft 16, and the connecting shaft 16 passes through the left large presser foot arm 4 and is fixedly connected with the left small presser foot arm 5, and the left presser foot 6 is connected with the left small presser foot arm 5 through the connecting pin 21. connected and the two can relatively swing around the connecting pin 21. Before the left large presser arm 4 presses down, the driving cylinder 10 moves ahead of time, and the left small presser arm 5 and left small presser arm 6 are driven to move through the driving cylinder 10 and the connecting shaft 16. The left presser foot 6 and the left small presser a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com