Prefabricated column perpendicularity adjusting method

A technology of prefabricated columns and cross-sections, which is applied in the direction of construction, building structure, and building materials processing, etc., which can solve the problems of many construction steps, waste of materials, and low efficiency, and achieve the effects of high construction efficiency, material saving, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

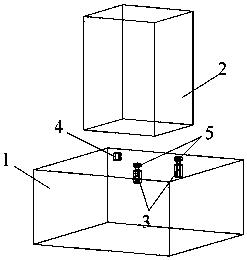

[0018] like figure 1 Shown: within the section range of the predetermined installation position of the prefabricated column 2 on the foundation or the lower floor 1, two internal threaded sleeves 3 are pre-embedded near the corners of the prefabricated column section.

[0019] Before the prefabricated column 2 is hoisted, place a small spacer 4 within the cross-sectional range of the prefabricated column's predetermined installation position, and the positions of the small spacer 4 and the two internally threaded sleeves 2 are triangular.

[0020] The bolt 5 is screwed in the internally threaded sleeve 3, so that the top surface of the bolt 5 and the top surface of the small block 4 are substantially at the same elevation.

[0021] The prefabricated column 2 is hoisted on the small pad 4 and the bolt 5, and the prefabricated column basically stands stably and then unh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com