Steel column splicing three-dimensional adjusting method

A steel column, three-dimensional technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of large application, unsafe, backward technology, etc., achieve significant social and economic benefits, high positioning accuracy, Reasonable effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

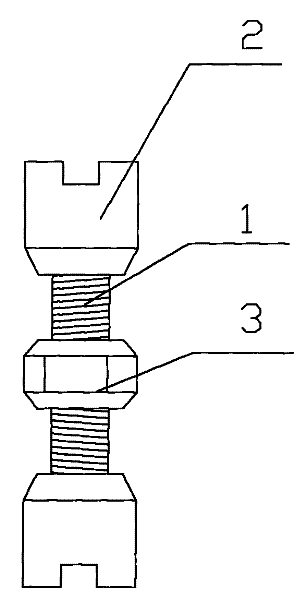

[0024] The steel column adjuster that the present invention adopts is developed spontaneously, and its structure is as follows figure 1 As shown, it is suitable for installing steel column sections with "O", "I", "ten", "T" or "□" structures, such as image 3 shown. The center of the steel column adjuster is a screw rod, the upper and lower ends of the screw rod are each fitted with a nut, the upper and lower parts of the screw rod have opposite thread directions, and a nut sleeve is fixed in the middle of the screw rod. The outer ends of the nuts at the upper and lower ends are provided with slots suitable for positioning with the steel columns.

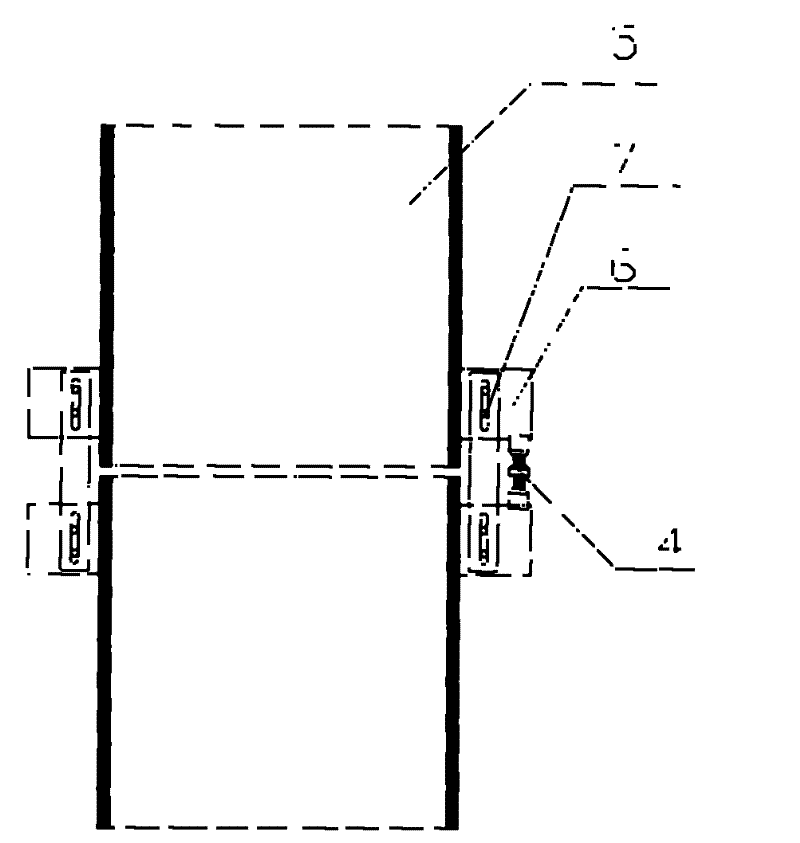

[0025] The actual adjustment method of the three-column steel column of the present invention is shown as follows figure 2 As shown, the specific steps are as follows:

[0026] 1. The factory processes and welds the lugs, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com