Safety anti-blocking construction process of soft aggregate in mine underground ultra-deep hole

A construction process and drilling technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve complex procedures, low aggregate conveying efficiency, affecting coal mine water blocking effect and construction period, etc. problem, to achieve the effect of solving the accumulation blockage

Active Publication Date: 2018-12-28

SHANDONG JIAOTONG UNIV

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to view more

Abstract

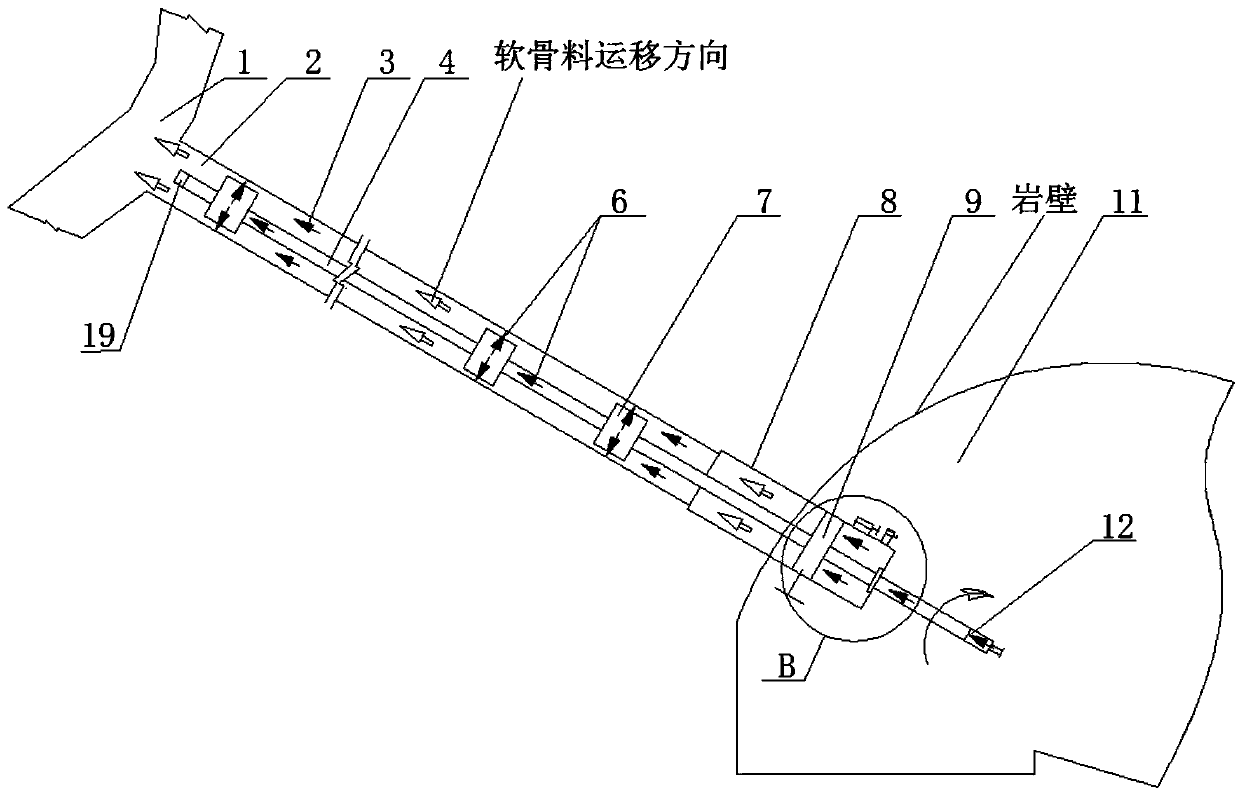

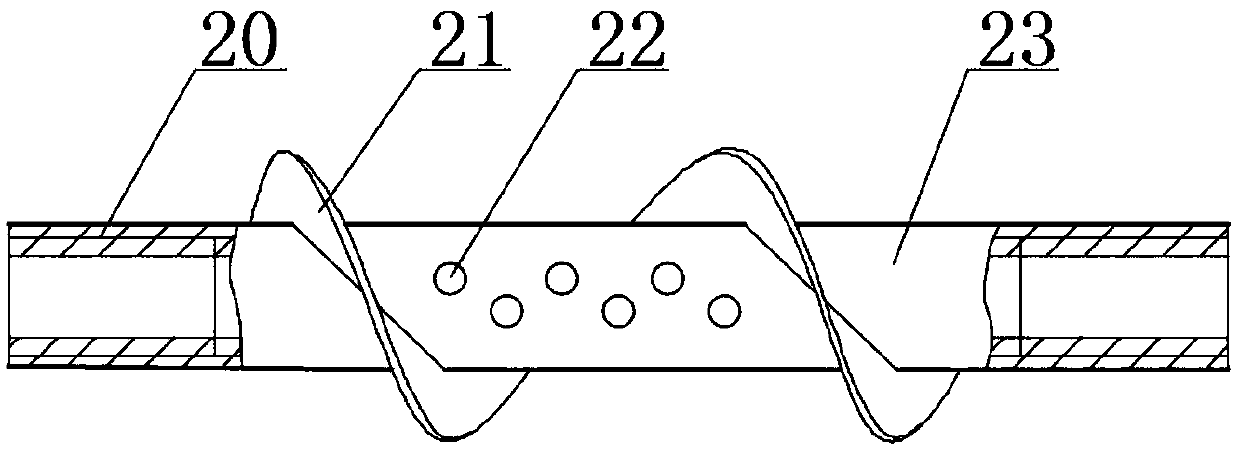

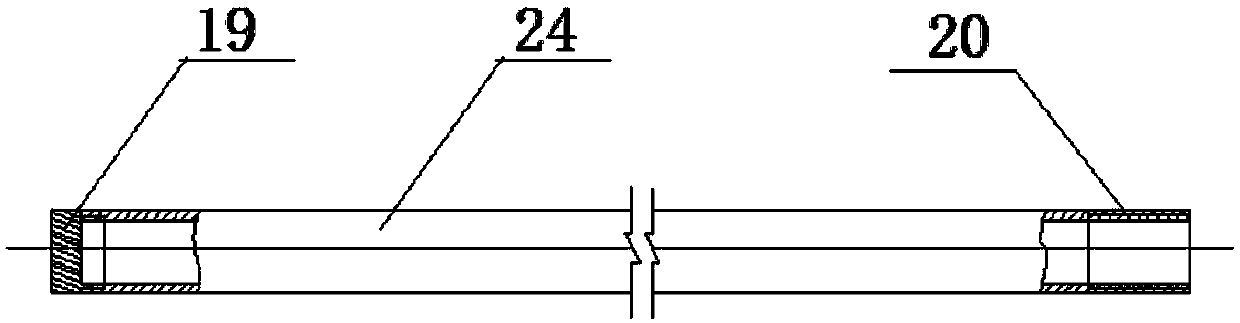

The invention relates to a safety anti-blocking construction process of soft aggregate in a mine underground ultra-deep hole. The safety anti-blocking construction process includes: drilling, judgingwhether the drilled hole and a water guide structure satisfy soft aggregate filling conditions, mounting a soft aggregate safety anti-blocking device into the drilled hole, filling the soft aggregateinto the water guide structure, starting a drilling rig at the same time to allow a drilling rig chuck to drive a central pipe to rotate rightwards, filling water into the central pipe at the same time through a water filling device connected to the head of the central pipe, ensuring that the high-temperature water flow in the drilled hole and the central pipe is constant before the water guide structure is filled with the soft aggregate until the soft aggregate is completely discharged from the drilled hole to the water guide structure, stopping the water filling and the soft aggregate filling, and taking out the soft aggregate safety anti-blocking device. By the safety anti-blocking construction process, the problem that the aggregate accumulates in the drilled hole and blocks the drilled hole during traditional soft aggregate filling which fills the soft aggregate into the mine underground hole.

Description

technical field The invention relates to a soft aggregate safety anti-blocking construction technology in ultra-deep boreholes in underground coal mines, and belongs to the field of prevention and control of underground water hazards in mines. Background technique Water inrush in coal mine mining face is one of the natural disasters affecting coal mining. Water inrush in coal mines not only threatens the safety of personnel at the operation site, but also threatens project safety and economic benefits. Long-term drainage measures will also increase coal mine operating costs. Therefore, it is one of the most effective methods to control mine water inrush to block the inrush water by drilling underground holes. Due to the deep buried depth of the mining face, some even exceed 1000m. There are many difficulties in downhole drilling construction and utilization of downhole drilling grouting. Especially when the borehole encounters a large water inrush fissure, it is extremely...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): E21B33/13

CPCE21B33/13

Inventor 王德明唐月李志鹏葛颜慧孙华东丁永玲贾雪娜

Owner SHANDONG JIAOTONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap