A board corner connection structure and its manufacturing process

A technology of corner connection and manufacturing process, which is applied in the direction of connection components, thin plate connection, material gluing, etc., can solve the problems of high cost of hardware connection parts and increase of furniture cost, and achieve the goal of improving resource utilization, saving costs and improving connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

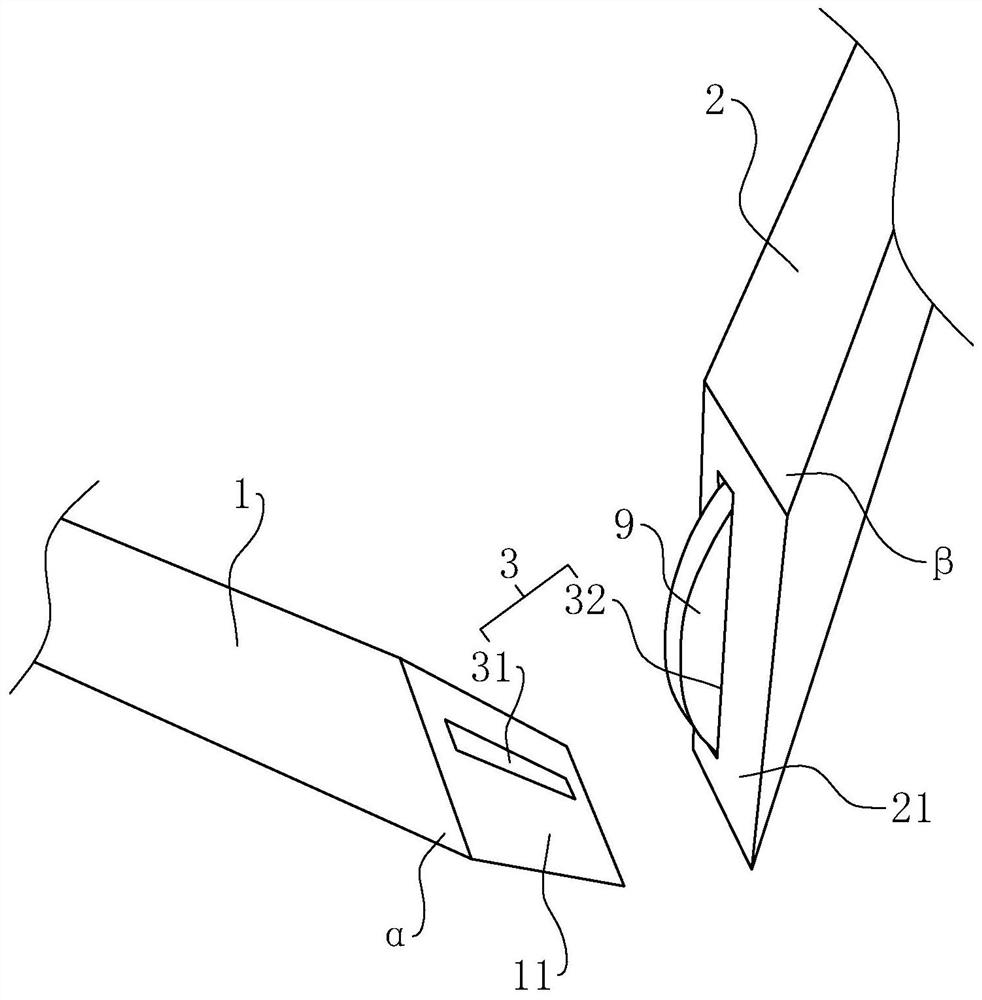

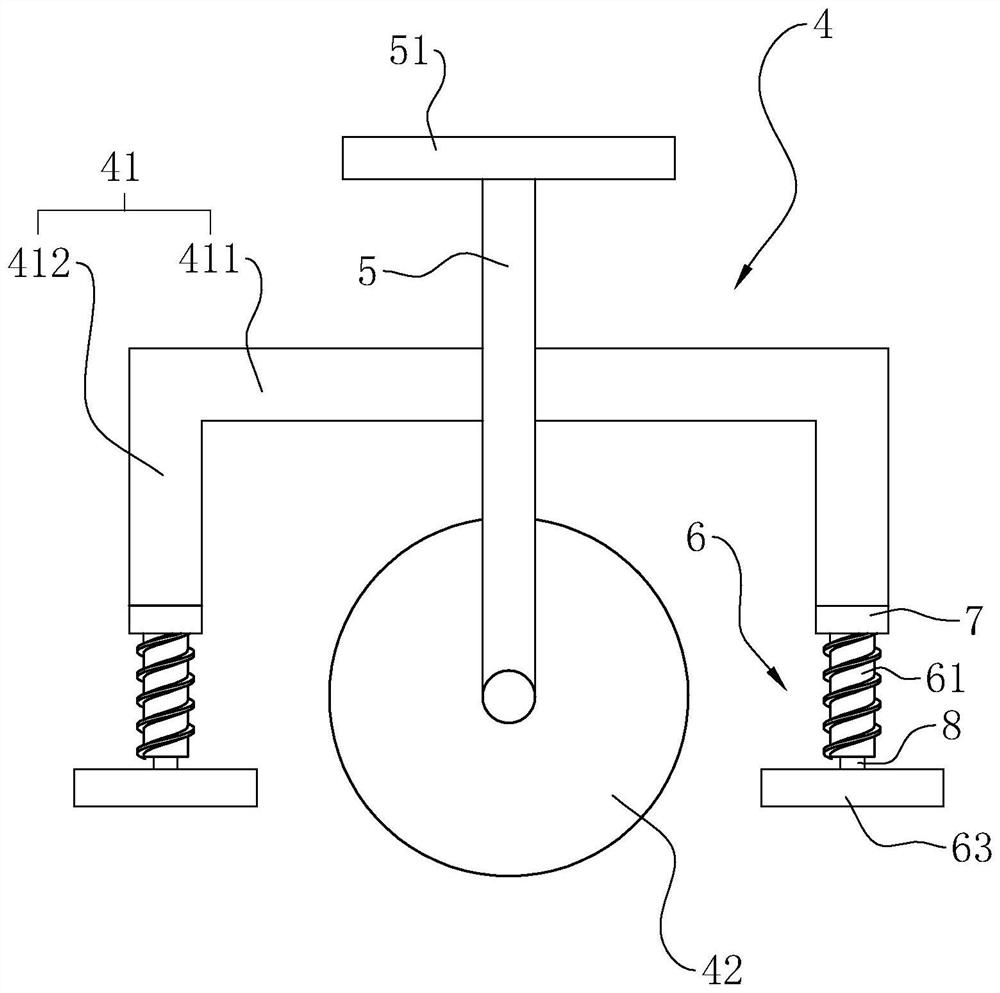

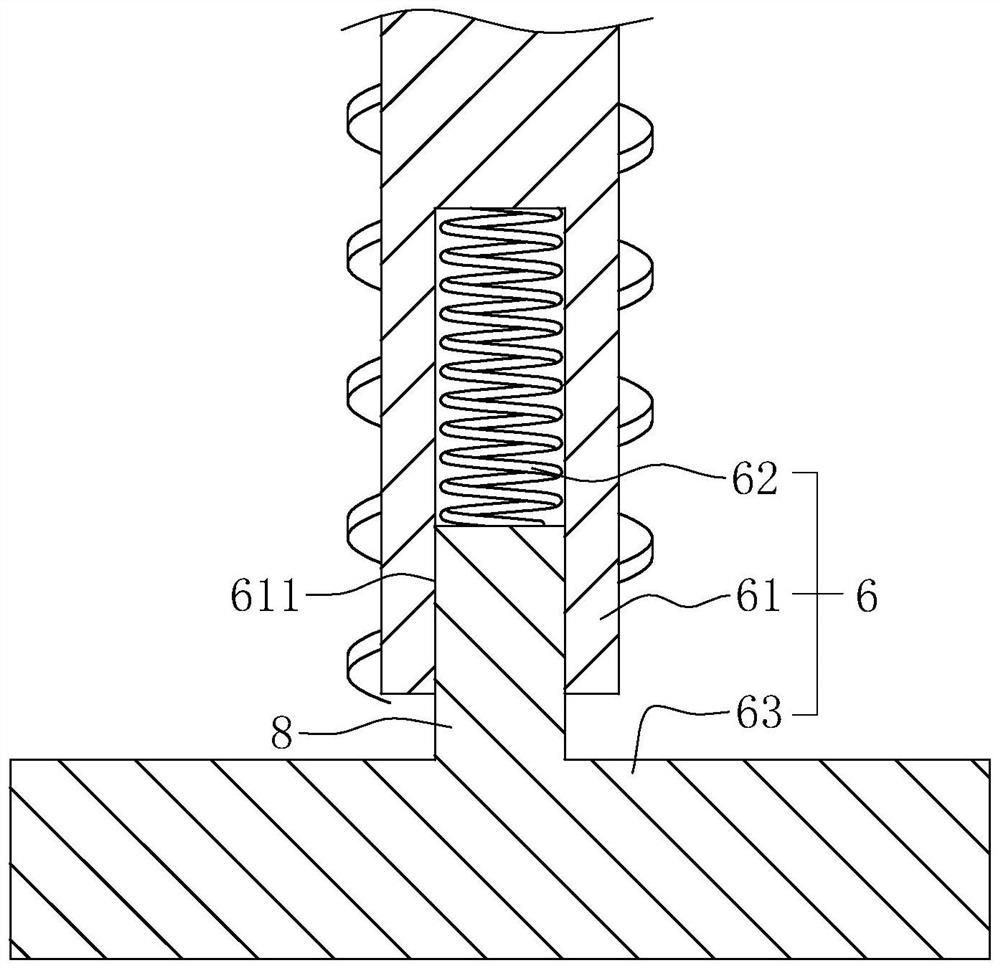

[0042] refer to figure 1 , is the manufacturing process of the board corner connection structure disclosed in the present invention. In this embodiment, the board corner angle γ (not shown in the figure) is 90 degrees as an example for illustration. The manufacturing process includes the following steps:

[0043] S1, purchase raw materials, form the first plate body 1, the second plate body 2 and the remaining material after cutting and processing, the thickness of the first plate body 1 and the second plate body 2 are the same. Cut the ends of the first plate body 1 and the second plate body 2 to form inclined first bonding surface 11 and second bonding surface 21 respectively. The inclination angle of the first bonding surface 11 is α, and the second bonding surface The inclination angle of the surface 21 is β, α=β=45 degrees, and γ=α+β.

[0044] S2, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com