Reactive force extrusion type stern shaft sealing device

A reaction force and sealing device technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inconvenient installation and complex structure of the sealing device, and achieve flexible use, ingenious design, and better sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

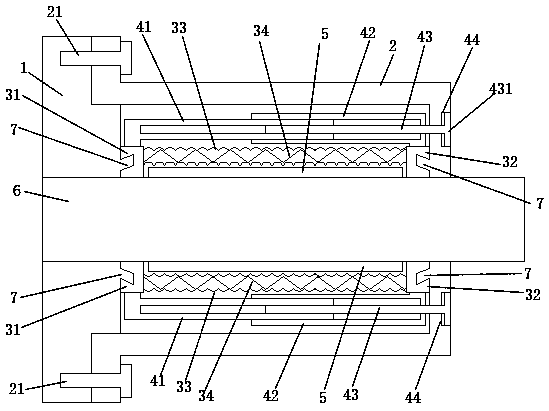

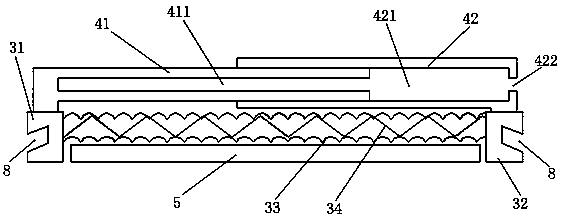

[0020] Such as Figure 1 to 2 As shown, a reaction force extrusion type stern shaft sealing device includes a bottom plate 1, a gland 2, a stern shaft 6, a sealing mechanism, and an extrusion ring 7. The gland 2 is installed on the bottom plate 1; a sealed cavity is enclosed between the gland 2 and the bottom plate 1. The stern shaft 6 is inserted into the sealed cavity; the sealing mechanism is installed in the sealed cavity. The sealing mechanism includes a first sealing ring 31, a second sealing ring 32, a sealing telescopic tube 33, a telescopic elastic body 34, and a locking assembly. The first sealing ring 31 and the second sealing ring 32 are arranged in parallel and coaxially; the section of the sealing telescopic tube 33 is a ring structure; the two ends of the sealing telescopic tube 33 are respectively solidified on the first sealing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap