Electric heater

A technology of electric heaters and heating chambers, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting the life of quartz and uneven heating, and achieve good energy utilization, uniform self-heating, The effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

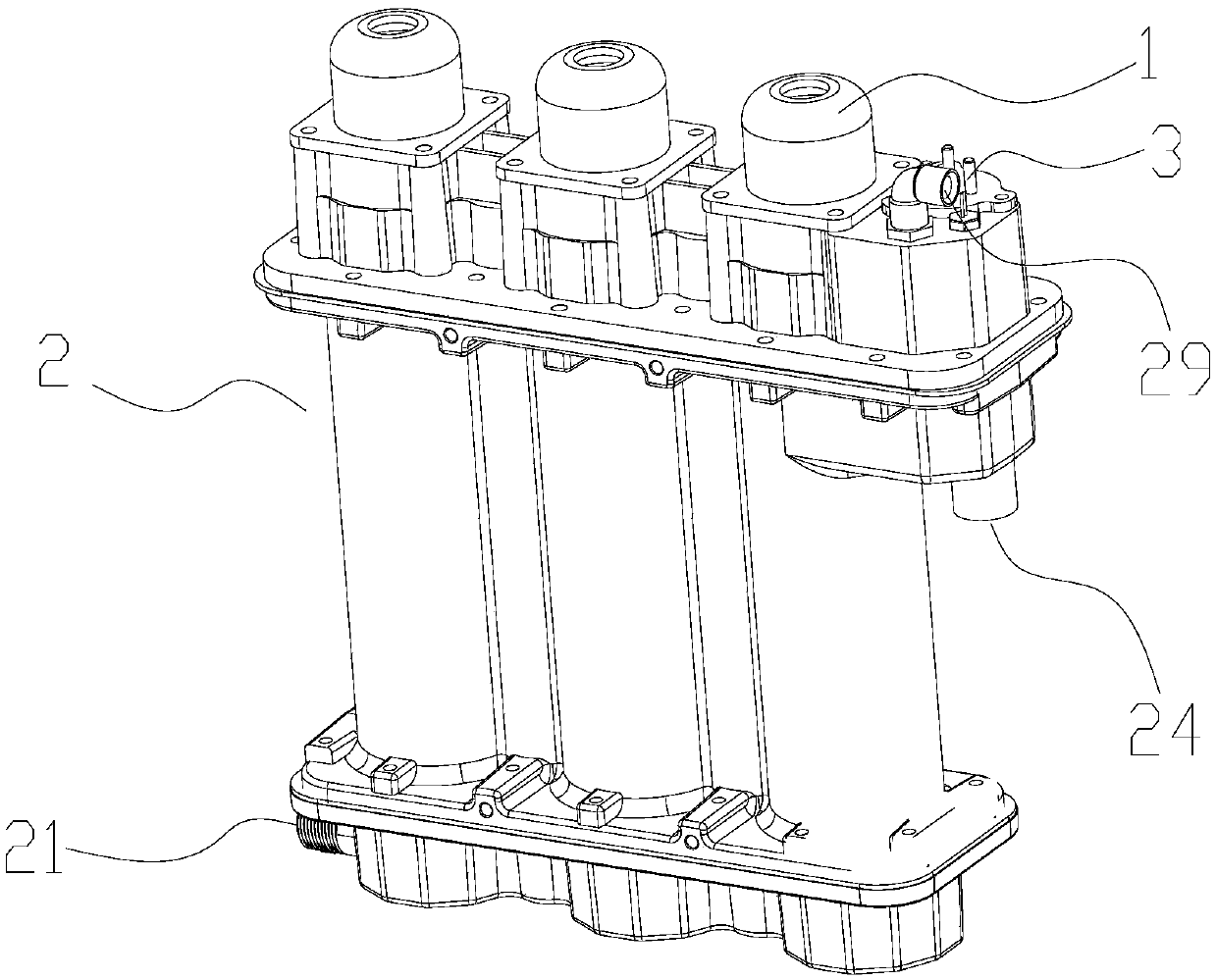

[0025] The application provides an electric heater, such as figure 1 As shown, including electric heating tube 1 and sleeve body 2;

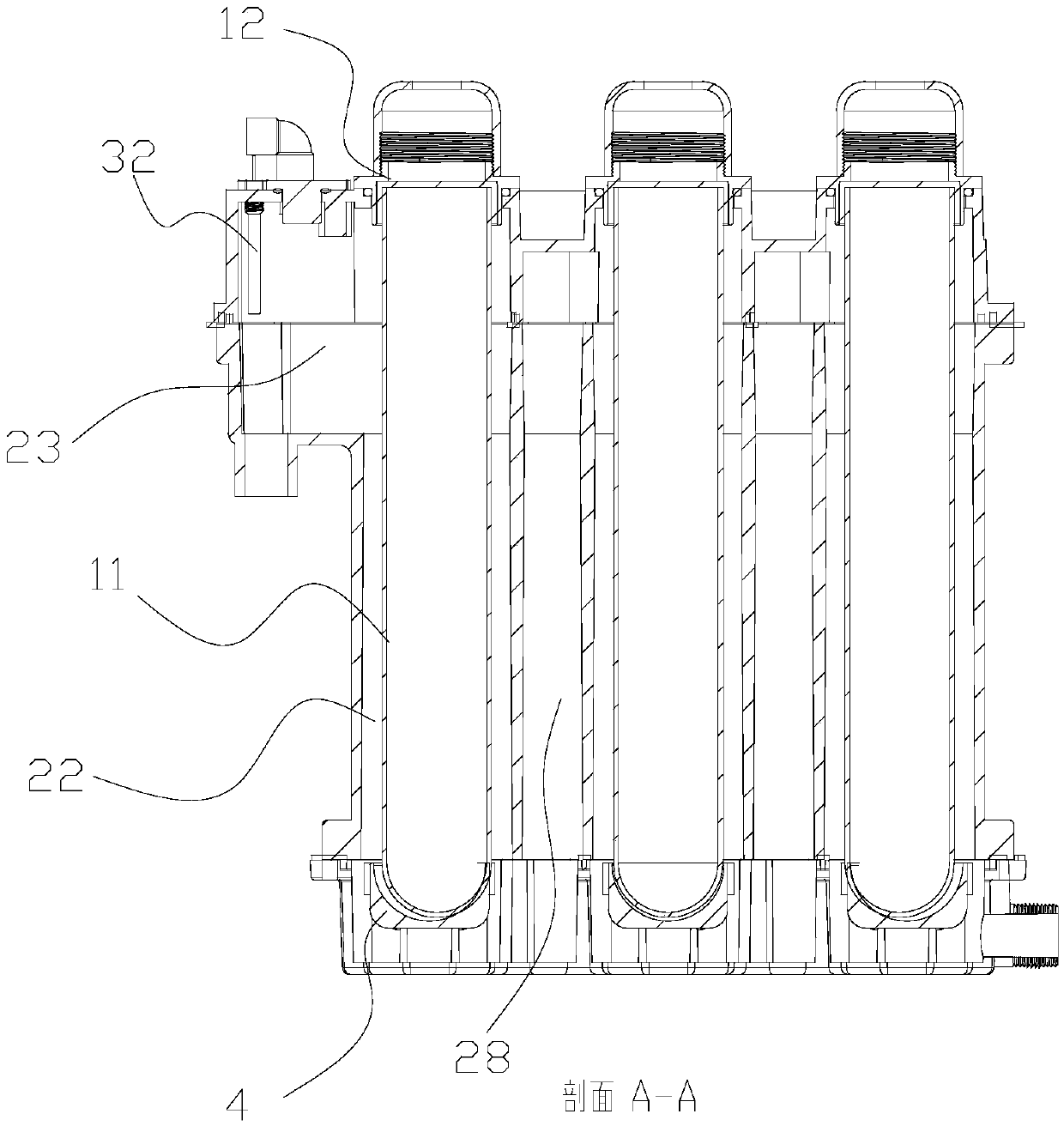

[0026] Such as figure 2 with 3 As shown, the electric heating tube 1 includes a quartz tube 11 and an end seal 12, the inner wall of the quartz tube 11 is attached with an electric heating film, and the end seal 12 is sleeved on the end of the quartz tube 11;

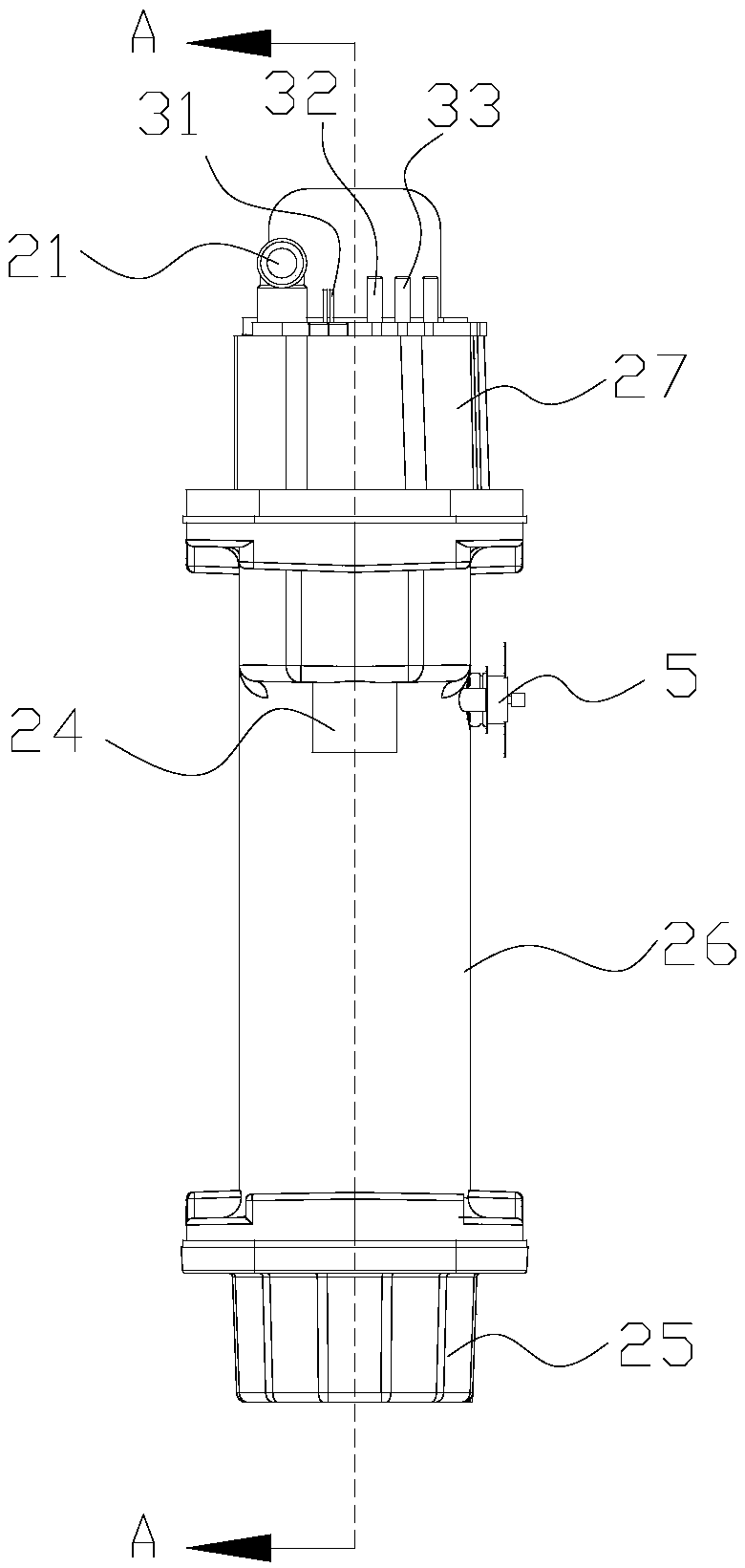

[0027] The sleeve body 2 is provided with a water inlet 21, a heating chamber 22, a detection chamber 23 and a water outlet 24 connected in sequence; the sleeve body 2 is provided with an installation port communicating with the heating chamber 22, and the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com