Pressurized tunnel lining structure accelerated corrosion test device and pressurization control method

An accelerated corrosion test and lining technology, which is used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as the inconsistency of the real environment of tunnel linings, the inability to truly reflect the corrosion environment of tunnel linings, and the need to improve reliability. To achieve the effect of reliable test basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

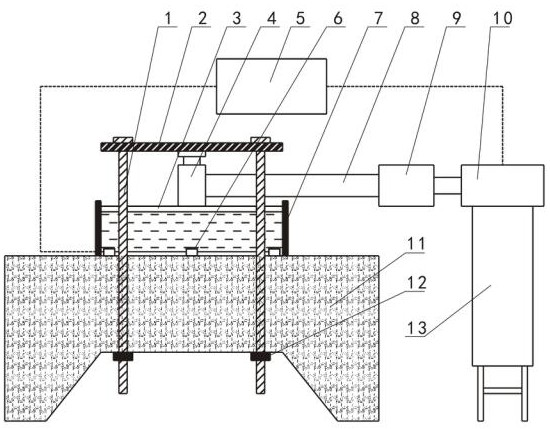

[0026] Such as figure 1 As shown, the pressurized tunnel lining structure accelerated corrosion test device of the present invention includes a water storage tank 7 arranged on the outside of the tunnel lining structure 11 and used for accumulating corrosive liquid, a vertical pull rod 1, a beam 2, a piston 4, and a sealing plate 3 , an electric cylinder 8, a reducer 9, a motor 10, a pressure sensor 6 and a controller 5. There are two vertical pull rods 1 and their lower ends pass through the tunnel lining structure 11 and are fixedly connected by bolts 12. The upper ends of the vertical pull rods 1 pass through After crossing the beam 2, it is fixedly connected by bolts 12. The transverse sealing plate 3 is placed on the top of the water storage tank 7 and sealed with the inner peripheral wall of the water storage tank 7 and can move up and down. The lower end of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com