Hot core box automatic mold splitting device

A hot core box and automatic technology, applied in the field of foundry core making, can solve the problems of damaging the inner cavity structure of the core box, consuming a lot of manpower and material resources, and inner cavity bumping, etc., achieving fast and convenient separation, wide application range, and guaranteed integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

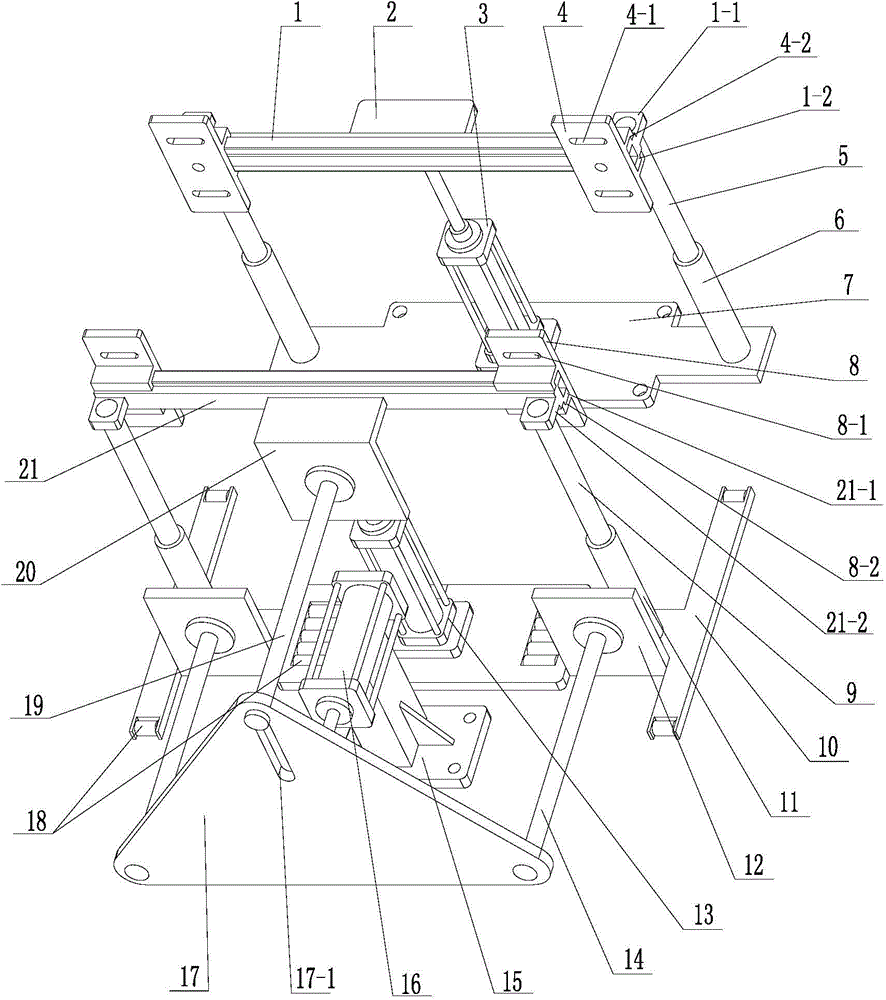

[0015] See figure 1 As shown, the hot core box automatic mold splitting device of the present invention includes a fixing mechanism for connecting the fixed mold of the core box and a moving mechanism for connecting the movable mold of the core box and moving horizontally.

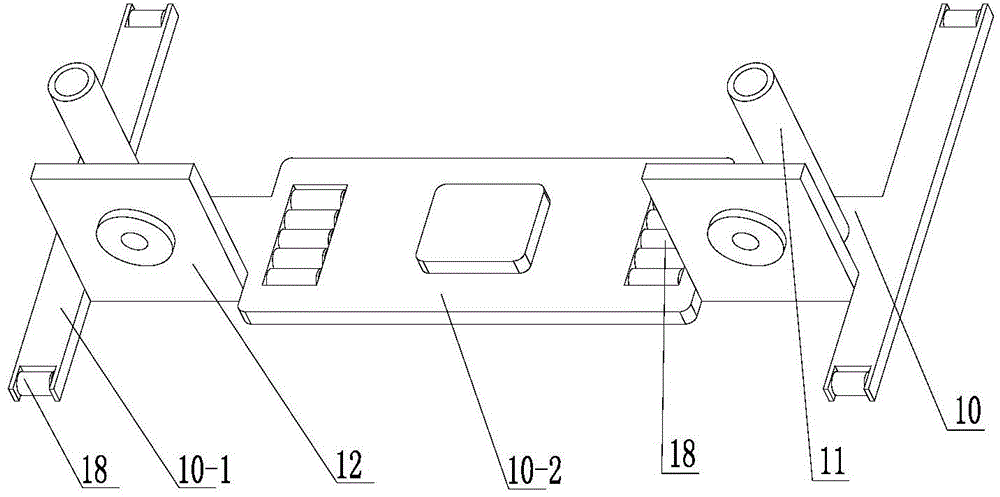

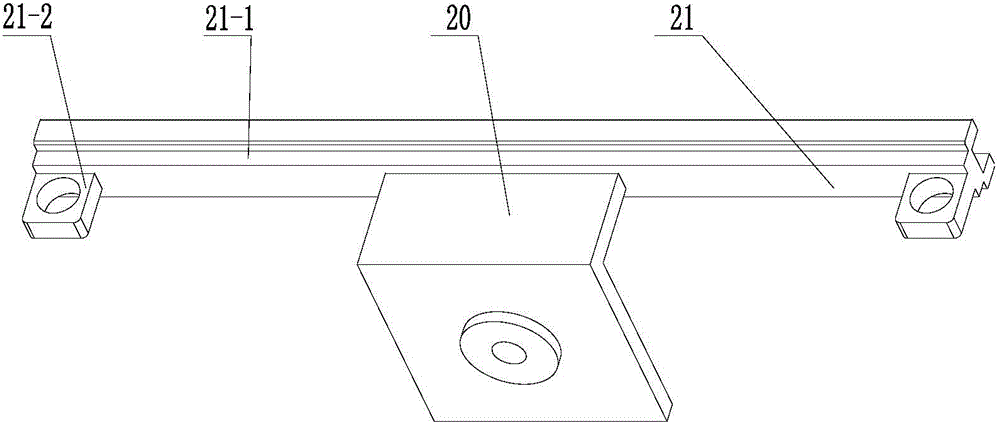

[0016] See figure 1 As shown, the fixing mechanism of the present invention includes a fixed base 7 and a first lifting actuator 3 installed on the fixed base 7, the first lifting actuator 3 is a cylinder or an oil cylinder or a motor, and the fixed base 7 is provided with the first lower connection 6, the fixed base 7 is provided with mounting holes, and the fixed base 7 can be installed on the workbench through fasteners. See figure 1 As shown, the moving side of the first lifting actuator 3 of the present invention is connected to the first guide rail beam 1, and the first lifting actuator 3 drives the first guide rail beam 1 to perform lifting motion, and the first guide rail beam 1 connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com