Device and method for detecting anchor rope grouting compactness in pre-embedding manner

A technology of compactness and anchor cable, which is applied in measurement devices, generation of ultrasonic/sonic/infrasonic waves, and analysis of solids using sonic/ultrasonic/infrasonic waves. Delay and other problems, to achieve the effect of convenient comparative analysis, convenient control and detection, and elimination of system delay errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

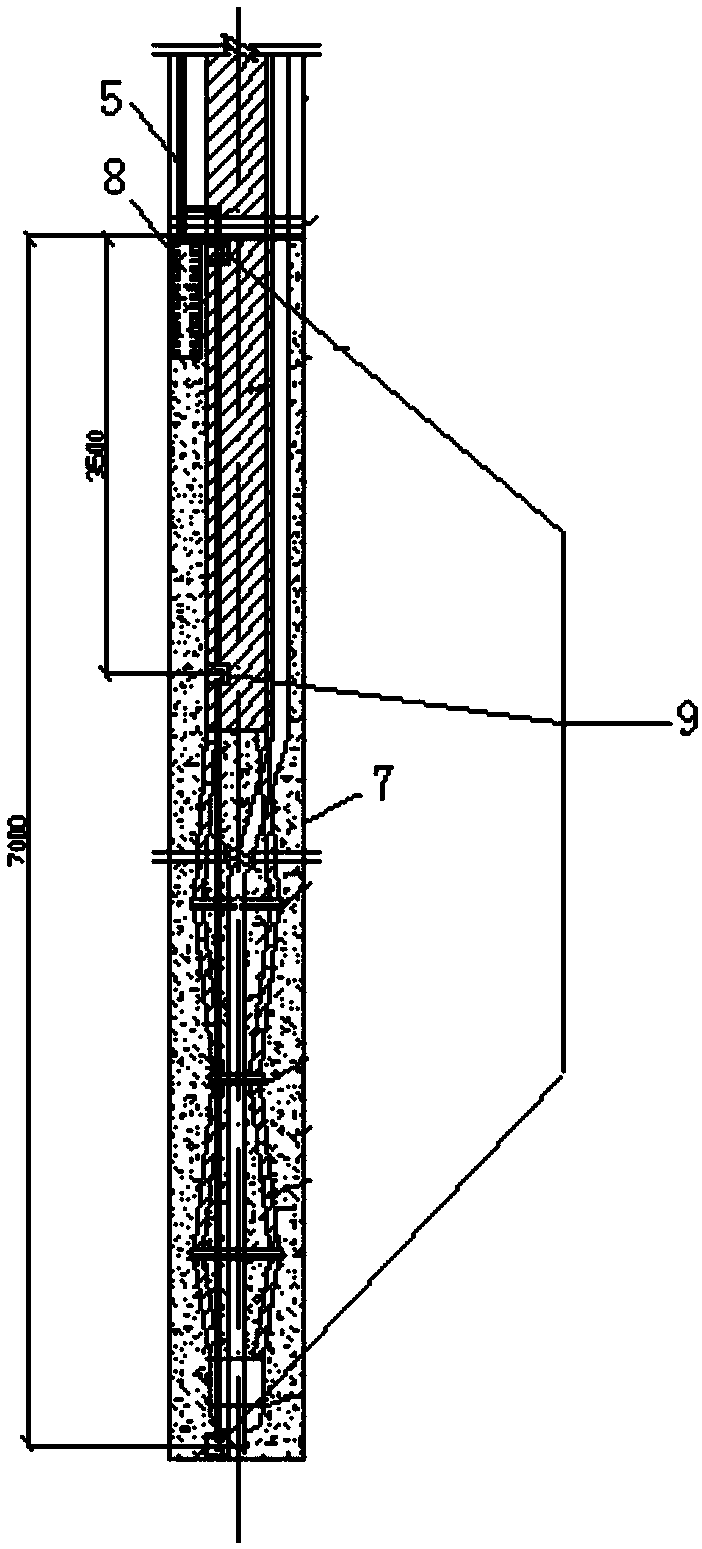

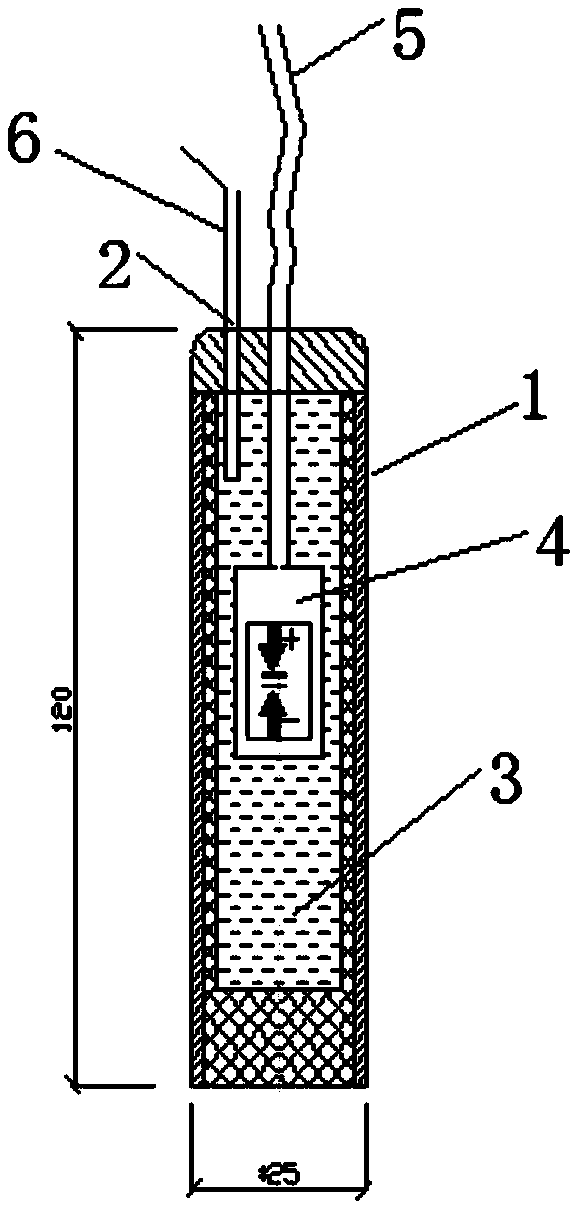

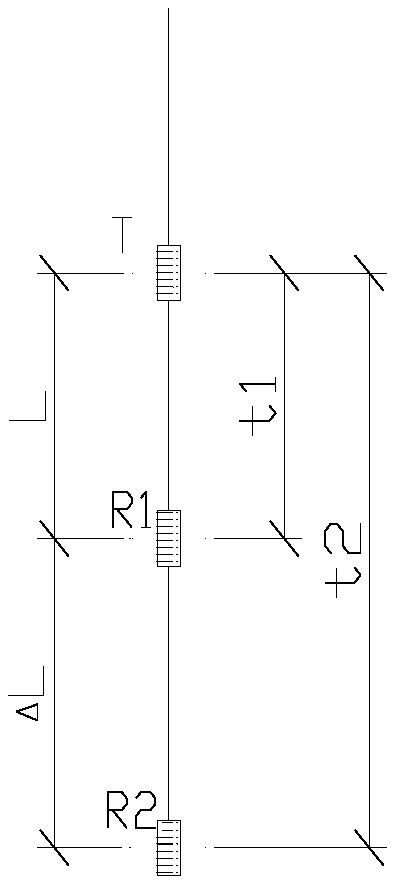

[0015] Such as figure 1 As shown, the detection device of the present invention includes an electric spark seismic source 8 embedded in the concrete of the anchorage section of the borehole 7; at least two acceleration sensors 9 are embedded in the concrete of the anchorage section of the borehole 7, and the two acceleration sensors The sensors are respectively buried in the middle and bottom of the borehole 7, and the two acceleration sensors 9 and the electric spark source 8 are electrically connected to the detector.

[0016] An acceleration sensor is embedded in the concrete of the anchor cable anchorage section at the top of the borehole 7, and the acceleration sensor is electrically connected to the detector. The advantages of setting the acceleration sensor: good performance in adapting to the environment during use, no matter it is shock, vibration or temperature difference change, it will not cause any interference to the use of the instrument; the cost is low, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com