Automatic glue dispensing machine

A dispensing machine and automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of inability to work continuously, insufficient dispensing area, space occupation, etc., to improve product quality and reduce the number of manpower , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

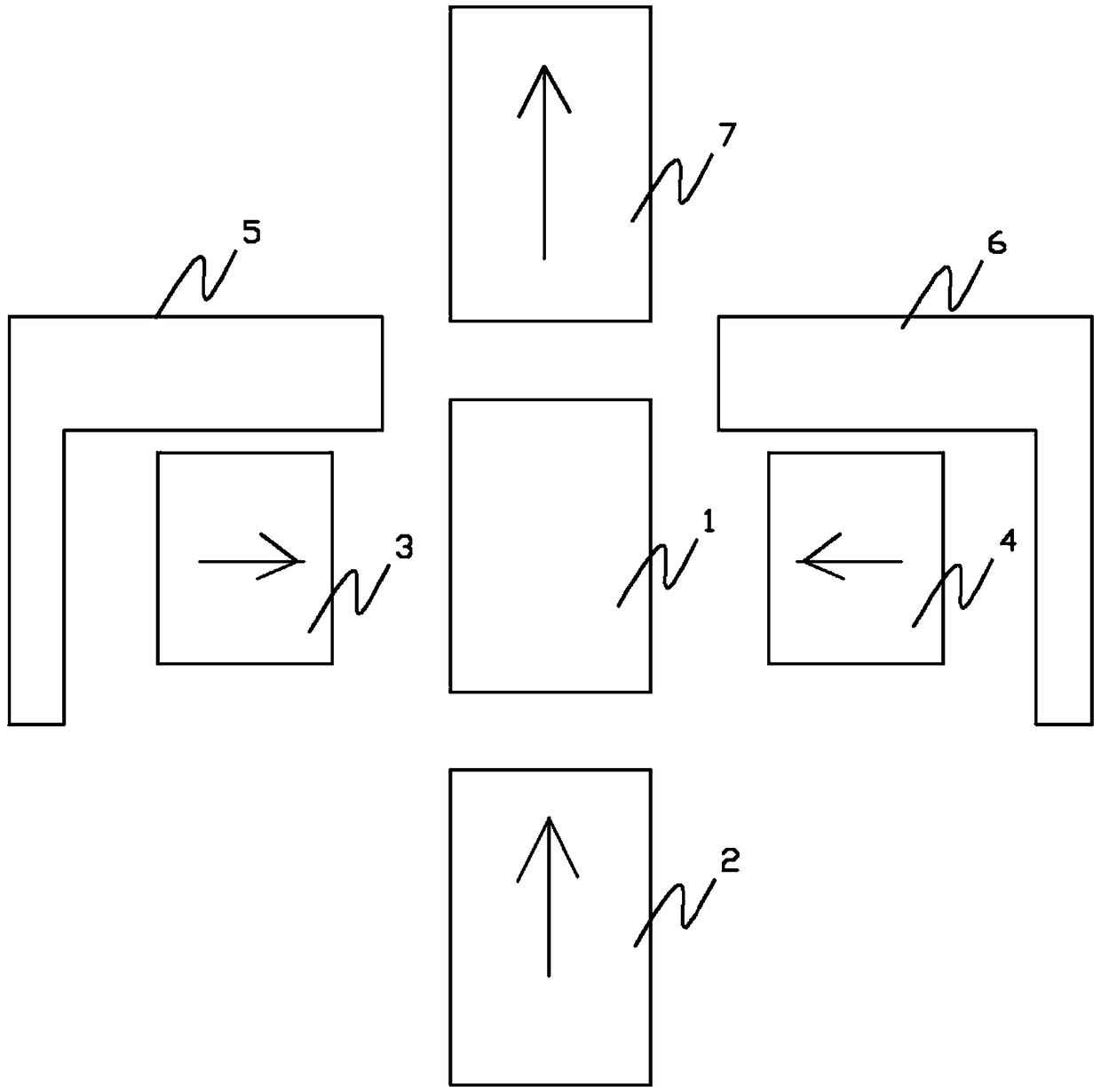

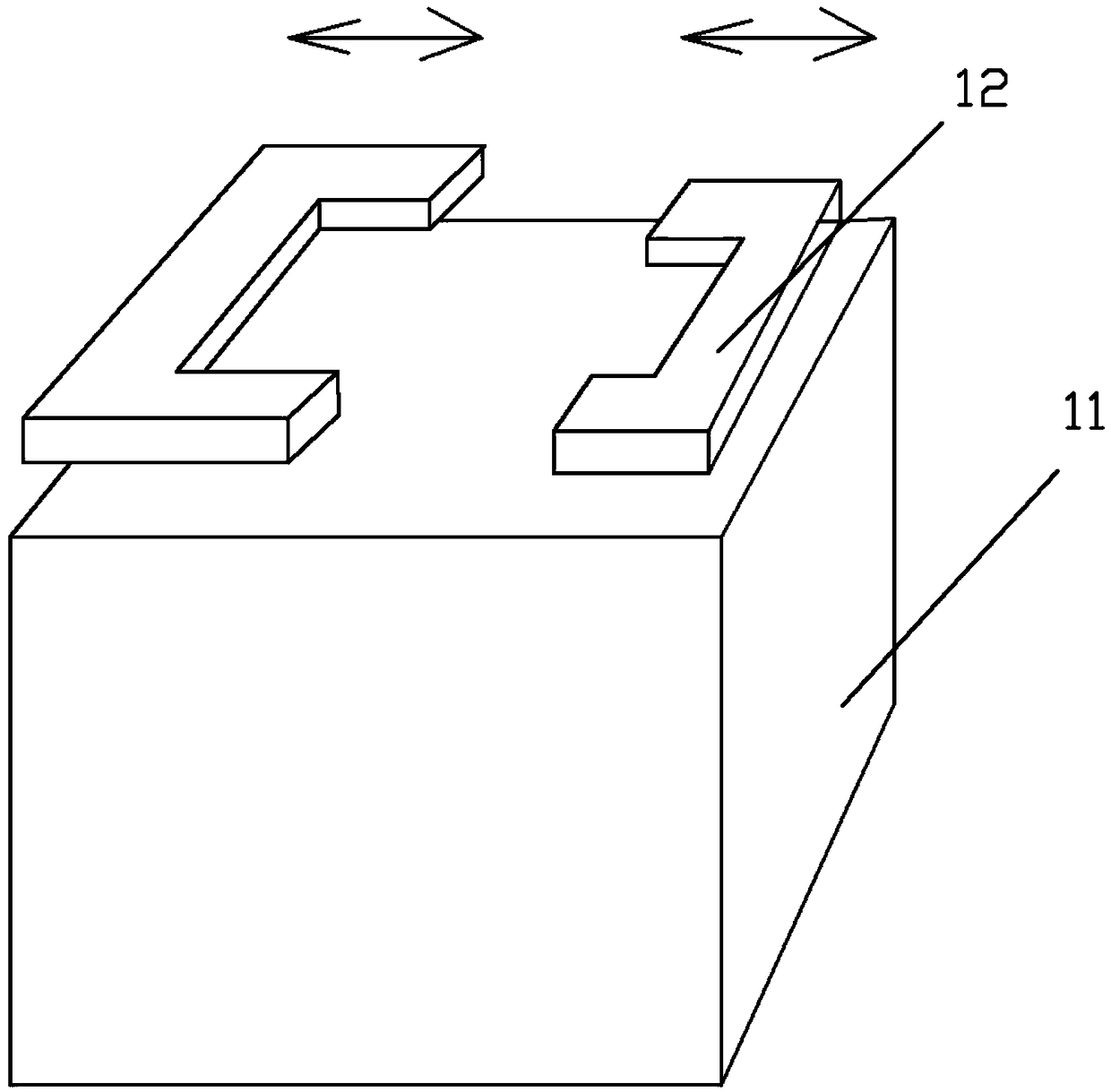

[0033] Such as Figure 1 to Figure 7 Shown, a kind of automatic dispensing machine of the present invention is characterized in that comprising:

[0034] Workpiece assembly device 1;

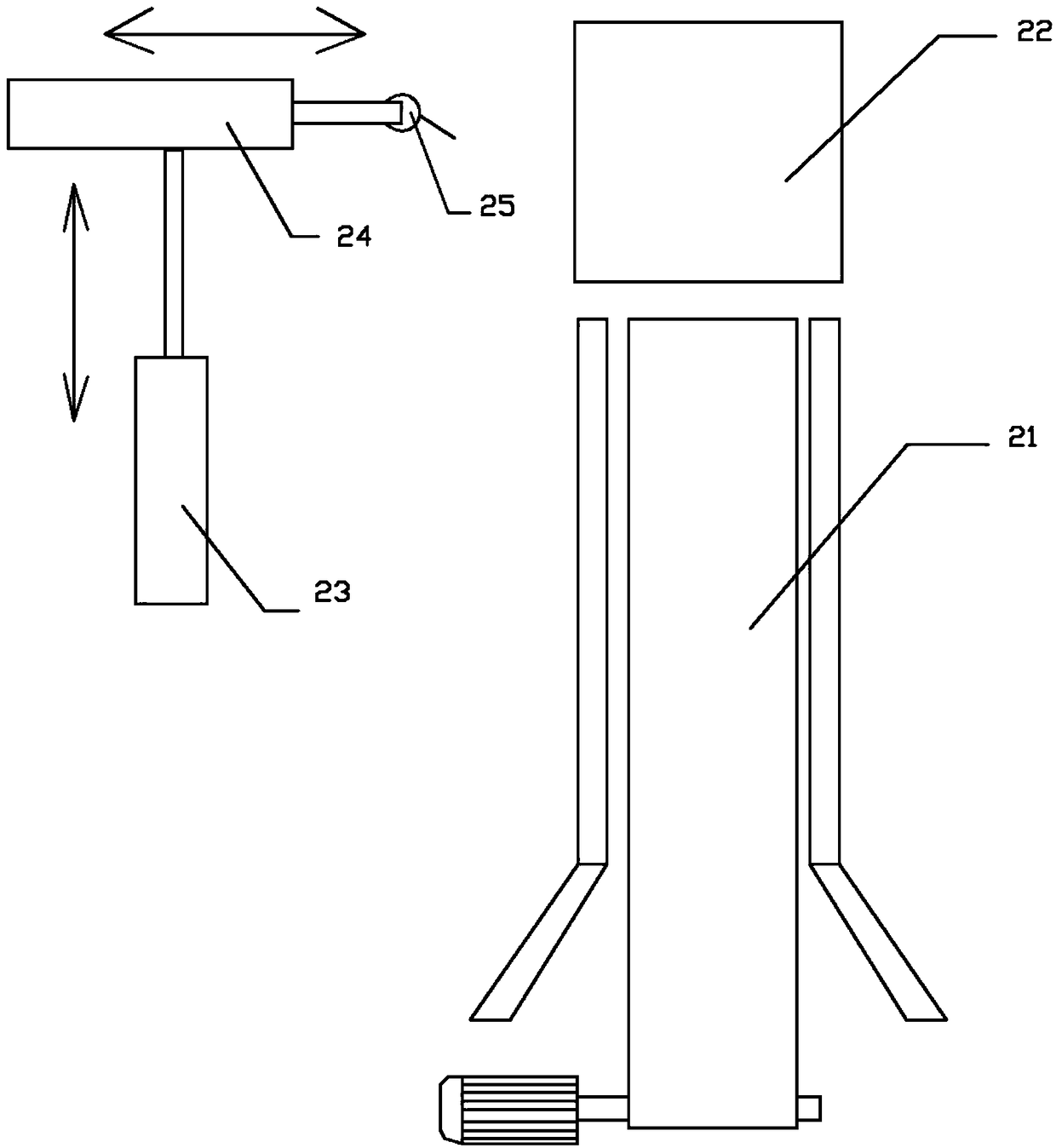

[0035] Skeleton feeding device 2, which is provided with the front end of workpiece assembly device 1;

[0036] The first magnetic core feeding device 5 is located at the left end of the workpiece assembly device 1;

[0037] The second magnetic core feeding device 6 is located at the right side end of the workpiece assembly device 1;

[0038] Feeding manipulator 7, above its workpiece assembly device 1;

[0039] The control device is electrically connected to the workpiece assembly device 1 , the skeleton feeding device 2 , the first magnetic core feeding device 5 , the second magnetic core feeding device 6 and the feeding manipulator 7 .

[0040] The integration of assembly and dispensing has been realized, which can greatly reduce the number of manpower, enable continuous production, stable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com