Inner and outer core pulling type injection molding mold and inner core pulling shaping structure

A technology for molding structures and injection molds, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of complexity and high manufacturing cost of core-pulling mechanisms, and achieve low manufacturing costs, high molding quality, and high structural compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

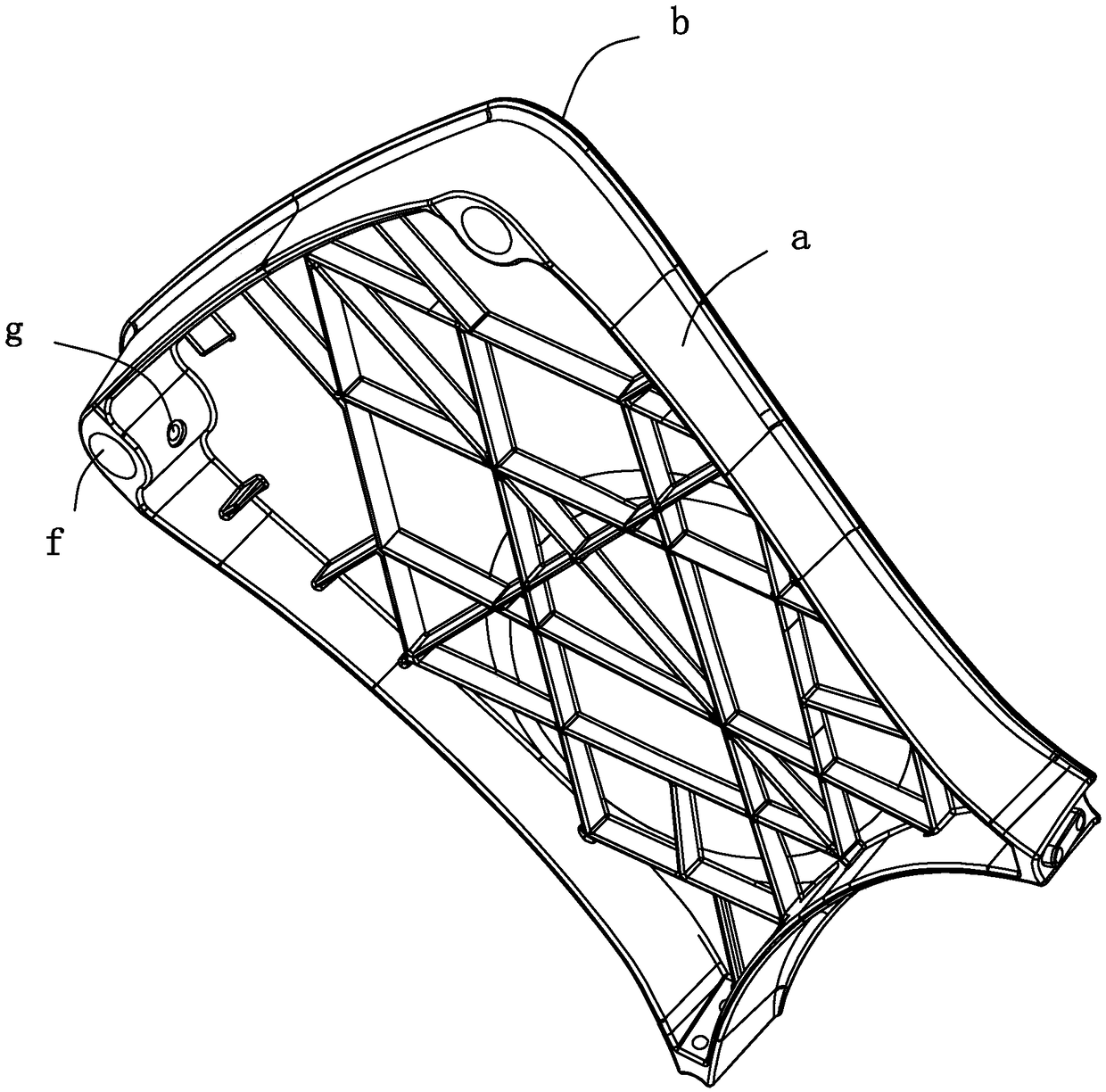

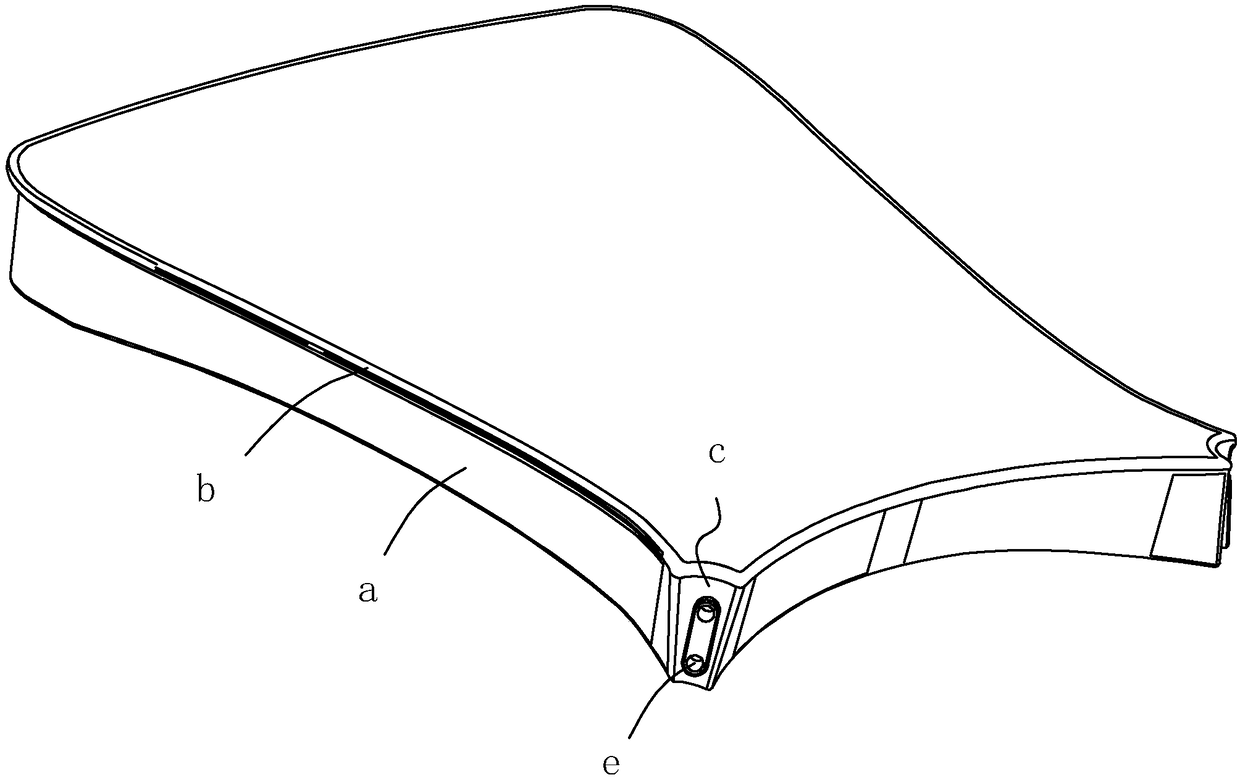

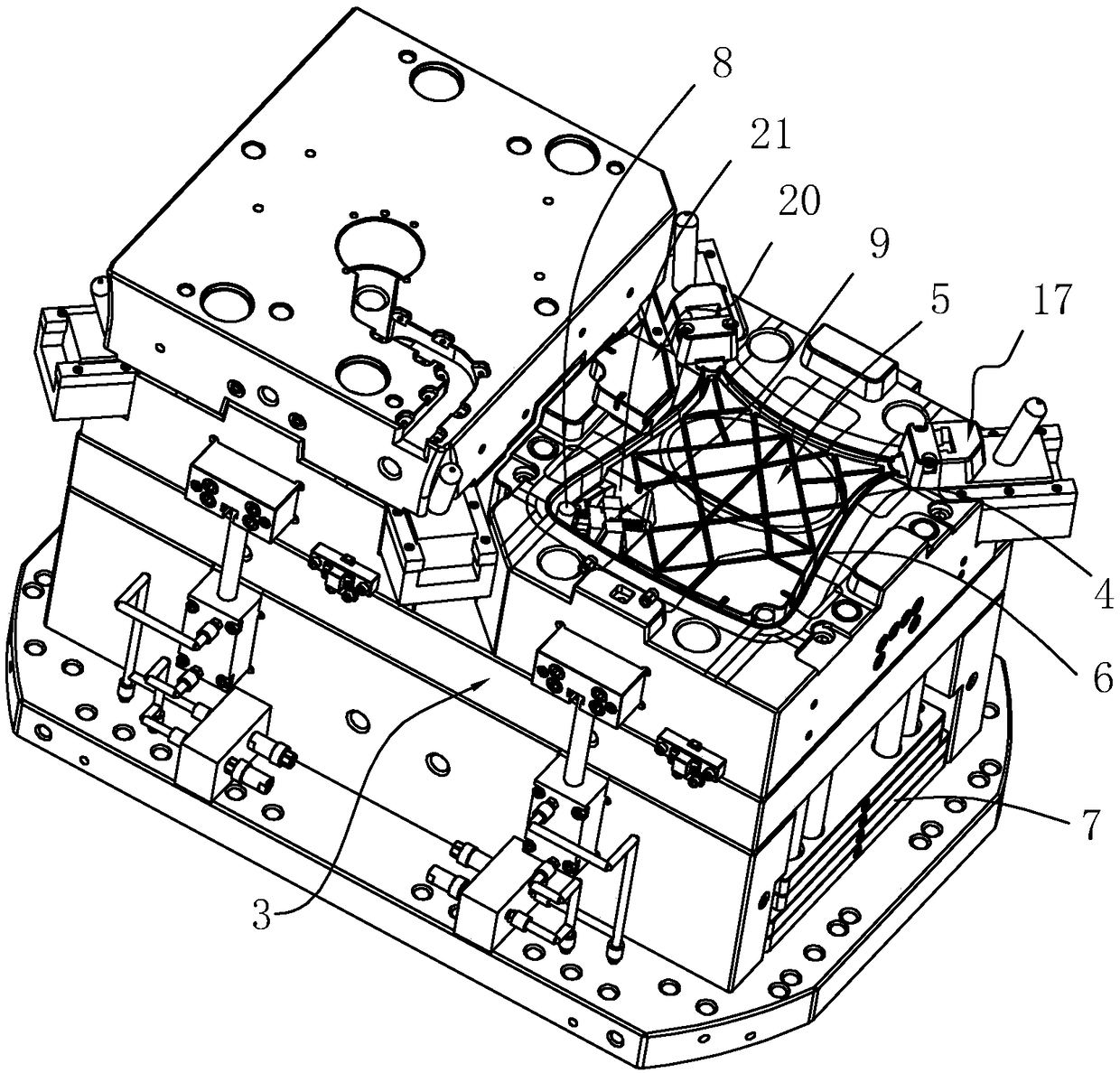

[0057] An inner core-pulling forming structure for forming such as figure 1 Inserting hole f and fastening hole g of the seat surface, see image 3 , which includes a first movable mold 3, an installation groove 4 is provided on the first movable mold 3, a core 5 is installed in the installation groove 4, and a molding cavity 6 is formed between the outer wall of the core 5 and the groove wall of the installation groove 4, forming Cavity 6 is used to form such as figure 1 as well as figure 2 The seat surface, the inner core-pulling molding structure is installed in the core 5.

[0058] see image 3 as well as Figure 4 , the inner core-pulling forming structure includes a forming rod 8, a driving rod 10, and a first driving part 44. One end of the forming rod 8 extends into the molding cavity 6 and is used to form the insertion hole f, and the other end of the forming rod 8 is connected to the first driving part 44. Section 44. One end of the drive rod 10 is inserted in...

Embodiment 2

[0064] An inner and outer core pulling injection mold for injection molding such as figure 1 as well as figure 2 The chair surface shown here.

[0065] see image 3 as well as Image 6 , its structure includes a first molding die 1, the first molding die 1 includes a first fixed mold 2, the first fixed mold 2 and the first movable mold 3 can be molded or parted with each other, and an external core-pulling structure 17 is included. The inner core-pulling molding structure in Example 1.

[0066] Among them, see Image 6 as well as Figure 7 , the first movable mold 3 includes a first mold base 14, a primary template 15 in a relatively fixed state relative to the first mold base 14, a secondary template 16 in a relatively movable state relative to the first mold base 14, and the outer core pulling The structure 17 includes a sliding seat 18 and an inclined guide post 19. The sliding seat 18 is slidably connected to the secondary formwork 16, one end of the inclined guide ...

Embodiment 3

[0076] Embodiment 3: The difference from Embodiment 1 and Embodiment 2 is that, see Figure 12 , a tank body 48 is provided in the tank cover 20, the end of the driving bolt 132 away from the forming block 12 is located in the tank body 48, the driving spring 131 is located in the tank body 48, and an elastic air bag 49 is also arranged in the tank body 48, and the driving bolt 132 is deviated from the end of forming block 12 and can produce extrusion force to elastic airbag 49, and the integral volume of elastic airbag 49 can become smaller, when elastic airbag 49 is not subjected to extrusion force, can return to original shape; 20 is provided with a blowing channel 50, one end of the blowing channel 50 is docked inside the elastic air bag 49, the other end of the blowing channel 50 faces the first boss 45, and the mouth of the blowing channel 50 near the first boss 45 is provided with One-way outlet valve 51.

[0077] When the forming block 12 moves away from the forming c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com