Thermal tranfer method

A technology of thermal transfer printing and transfer printing paper, applied in the direction of copying/marking methods, printing, etc., can solve the problems of strong professionalism, difficulty in implementation by ordinary people, single pattern, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The thermal transfer printing method of the present invention is used to transfer and fix the pattern from the first carrier to the second carrier of cloth. Wherein, the first carrier is transfer paper with a release layer on the surface, and the second carrier can be fabrics such as clothes and bags.

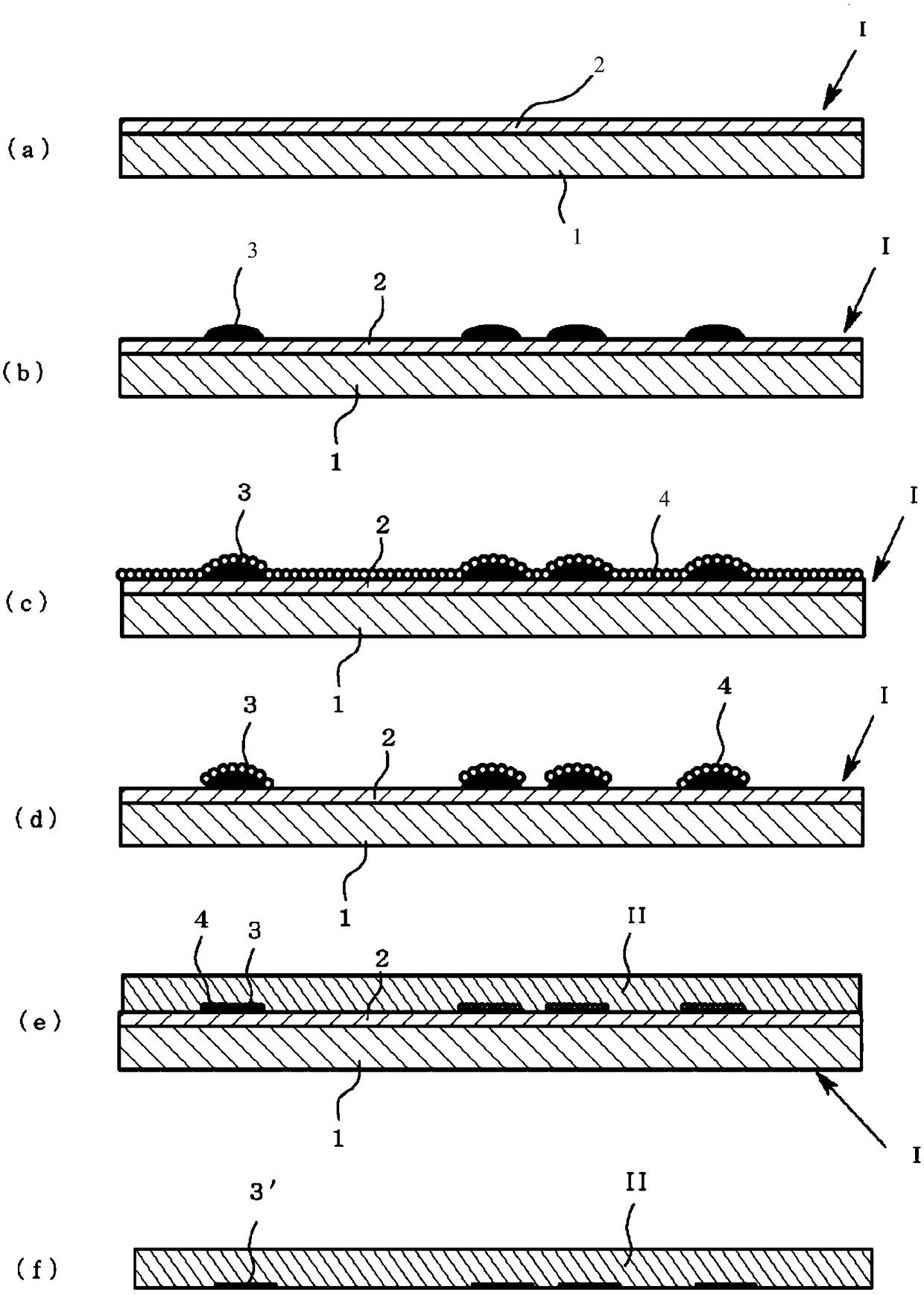

[0017] Please refer to figure 1 , the specific thermal transfer method is as follows:

[0018] Sub-figure a shows the structure of the first carrier I, where 1 is the base material and 2 is the release layer.

[0019] Use pigments to draw pattern 3 on the first carrier I, as shown in sub-figure b;

[0020] Sprinkle resin powder 4 on the surface of the drawn pattern, shake the first carrier I in the horizontal direction, so that the resin powder 4 is fully attached to the surface of the drawn pattern, as shown in sub-figure c. Then shake the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap