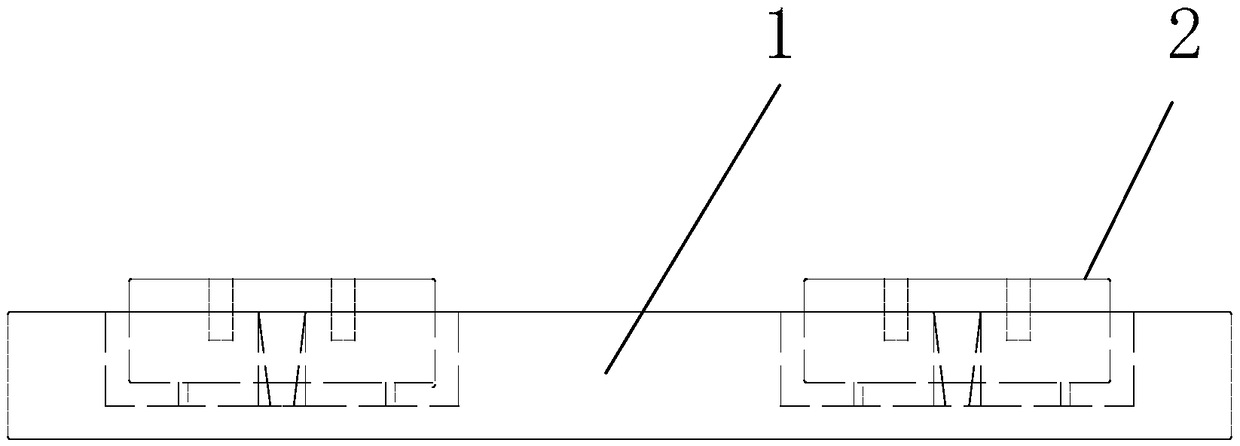

A multi-stage prefabricated track plate

A track slab and multi-stage technology, applied in the field of rail transit, can solve the problems of high cost of prefabricated molds, difficult precision control, low mold cycle utilization rate, etc., to reduce maintenance requirements and costs, reduce production costs, and increase cycle use rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

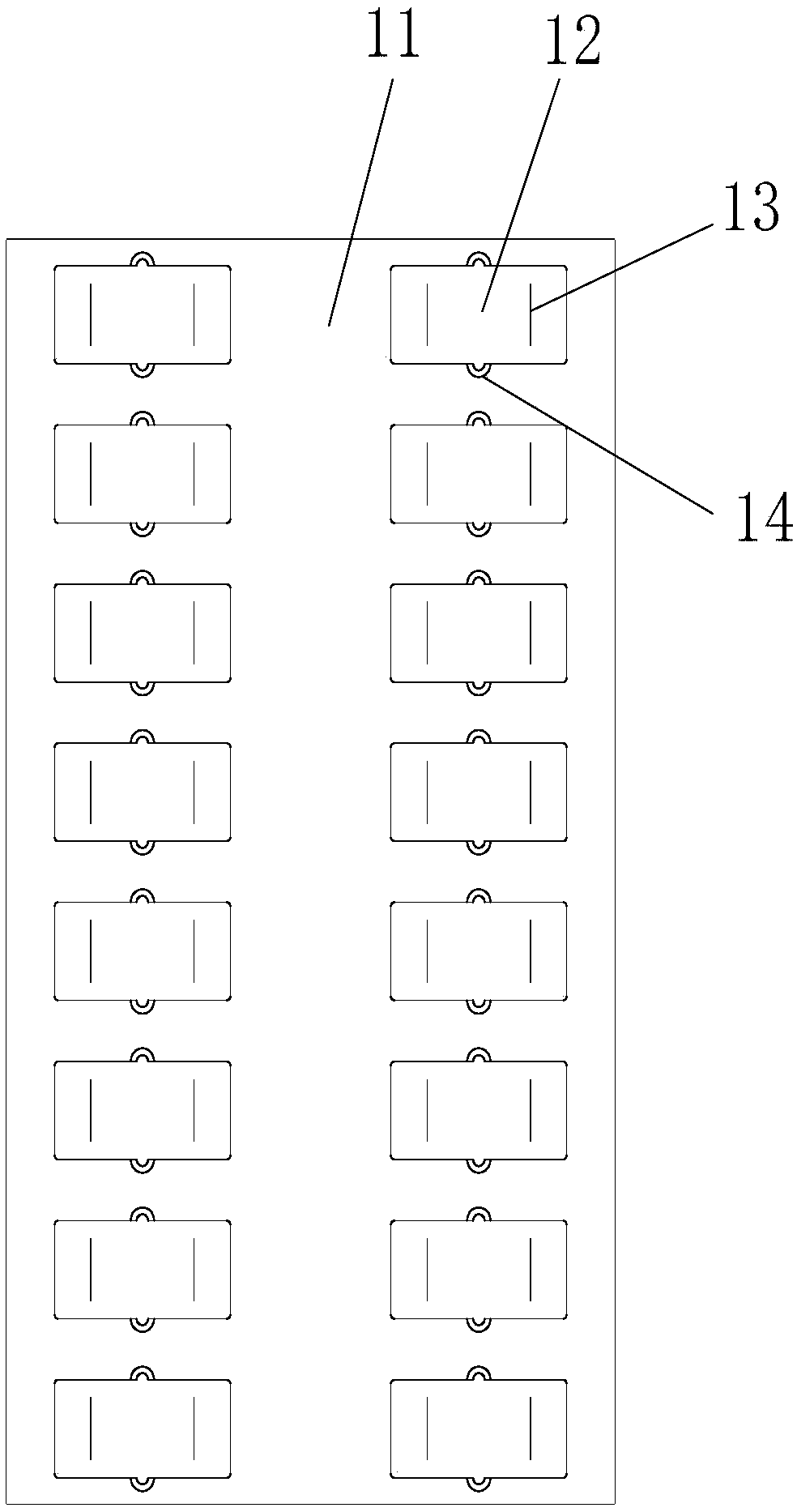

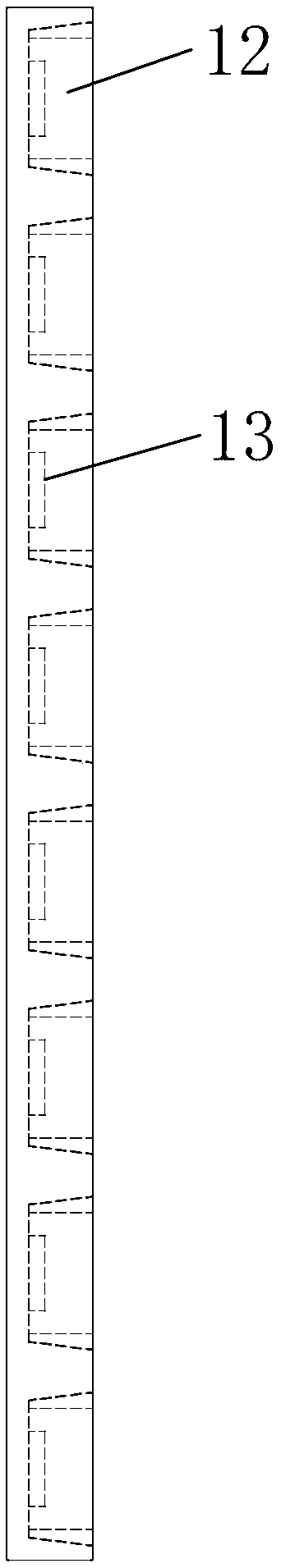

[0046] Such as Figure 8-14 As shown, in this embodiment, the number of reserved grooves 12 is multiple, and the plurality of reserved grooves 12 are distributed in a row along the longitudinal direction of the track on the lower plate 1, and at both ends of each block 21 respectively A pre-embedded casing 23 for installing rail fasteners is provided. Three grouting holes 14 are arranged on both sides of each reserved groove 12 . It should be noted that those skilled in the art should understand that in some other embodiments of the present invention, grouting holes 14 can also be provided on one side of the reserved groove 12, and in addition, the number of grouting holes 14 can also take oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com