Combined type labyrinth sealing bearing

A labyrinth seal, combined technology, used in bearing elements, shafts and bearings, rigid brackets of bearing components, etc., can solve problems such as instability, difficult disassembly, and loose bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

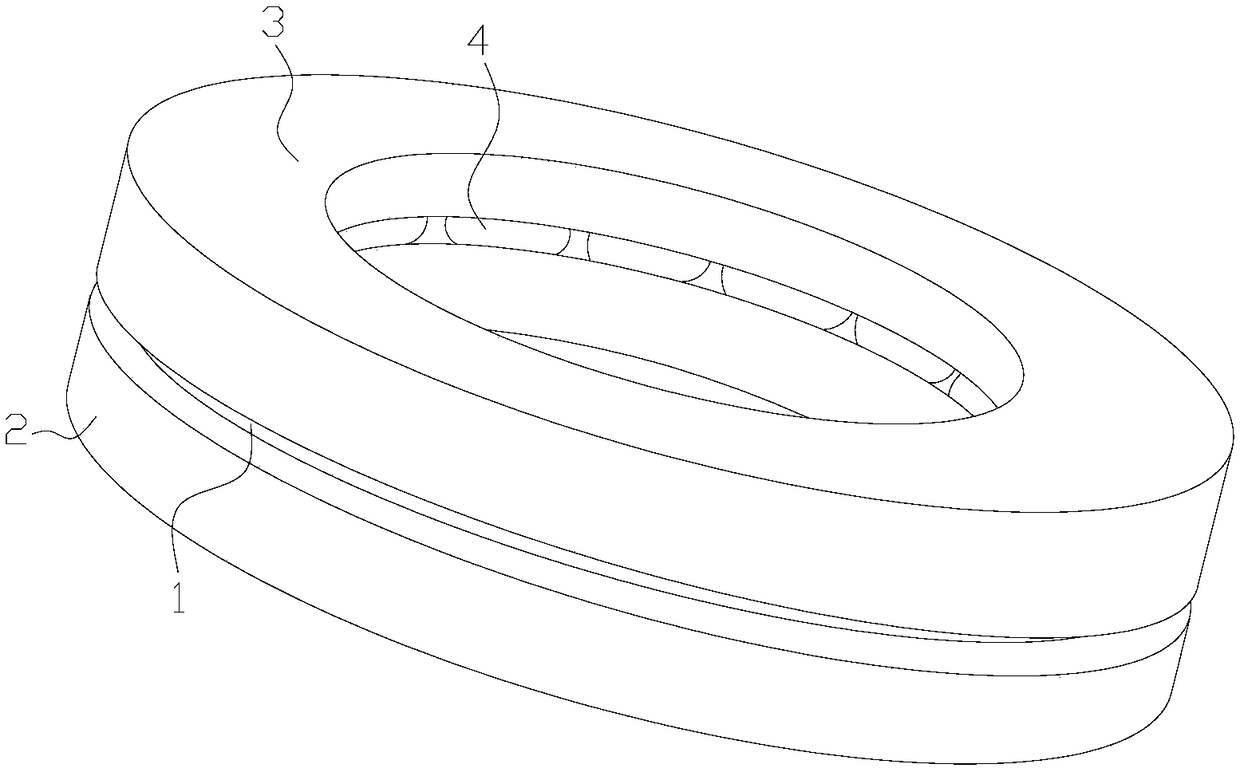

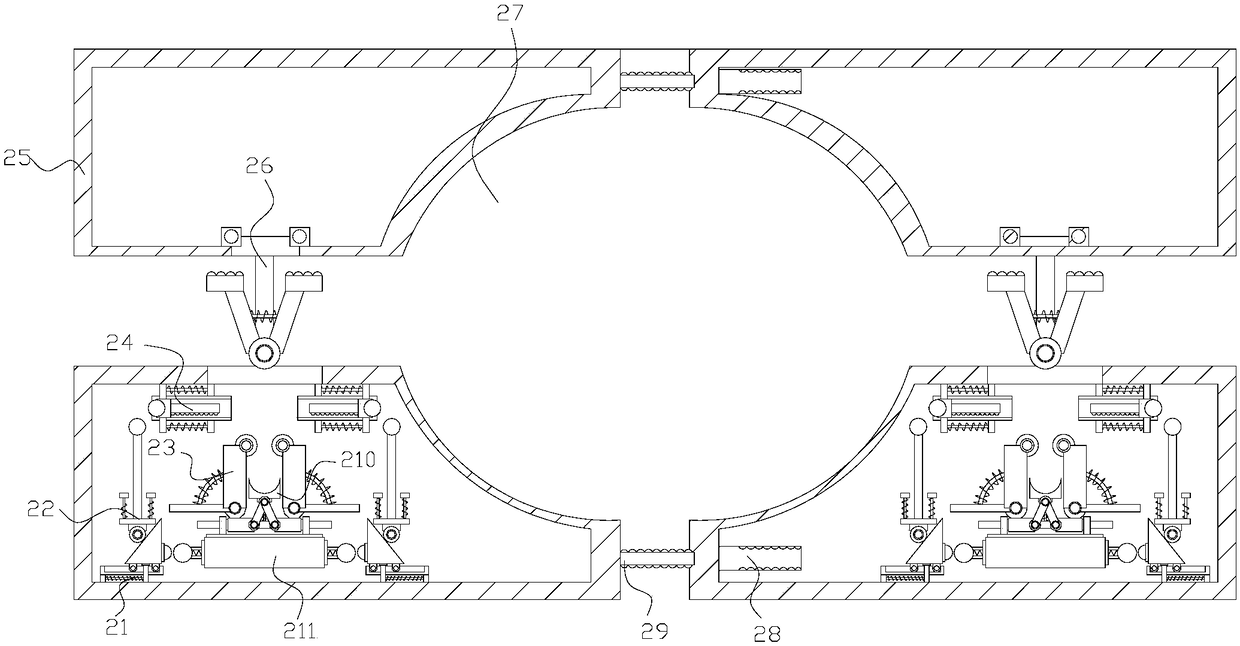

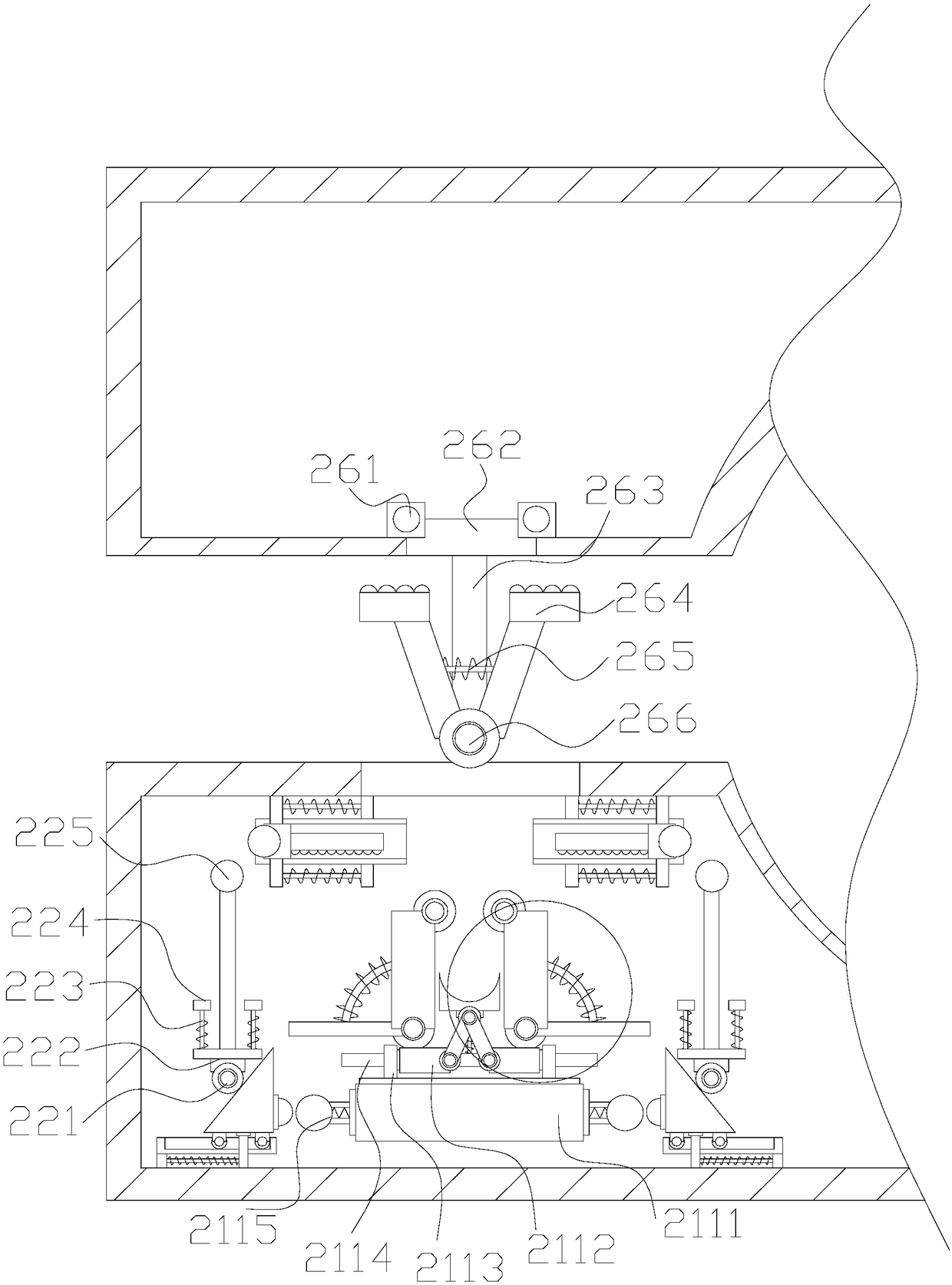

[0024] see Figure 1-Figure 6 The present invention provides a combined labyrinth seal bearing, including an installation alignment end 1, a labyrinth buckle seal shaft housing 2, a buckle cover 3, and a ball 4. The installation alignment end 1 is embedded in the labyrinth buckle seal shaft housing 2 and is located On the same axis, the labyrinth buckle seal shaft housing 2 and the buckle cover 3 are parallel to each other and located on the same center line, and the ball 4 is embedded between the buckle cover 3 and the labyrinth buckle seal shaft housing 2 and moves connection, the labyrinth buckle seal shaft housing 2 includes a magnetic field pusher 21, a magnetic field end 22 to be pushed, a stressed extrusion body 23, a buckle to be pushed 24, a protective shell 25, a buckle device 26, a ball installation groove 27, The friction groove 28, the moving friction rod 29, the forced extrusion trigger device 210, and the magnetic field end 211 to be activated.

[0025]The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com