Weld pass three-dimensional shape detection method based on surface structured light

A technology of three-dimensional shape and detection method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of restricting the precise research of metal additive manufacturing process and parameters, unable to fully express three-dimensional information, and limited information dimensions , to achieve the effect of low cost, simple installation, comprehensive and accurate description

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

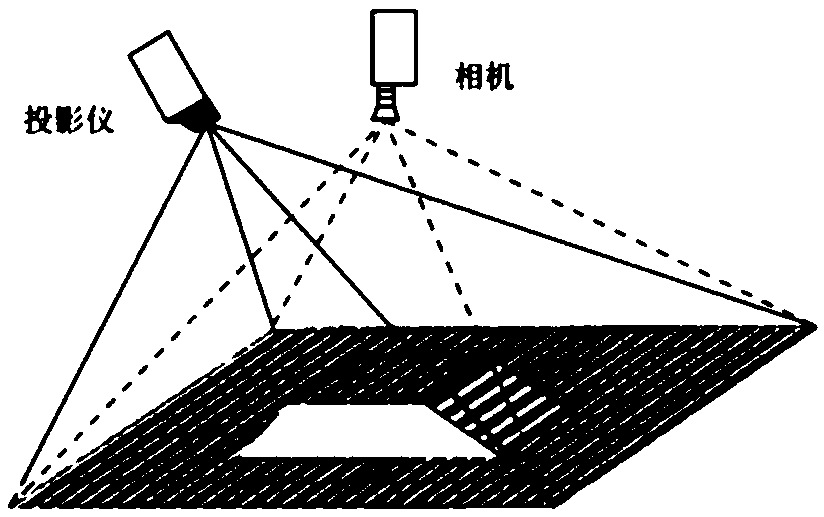

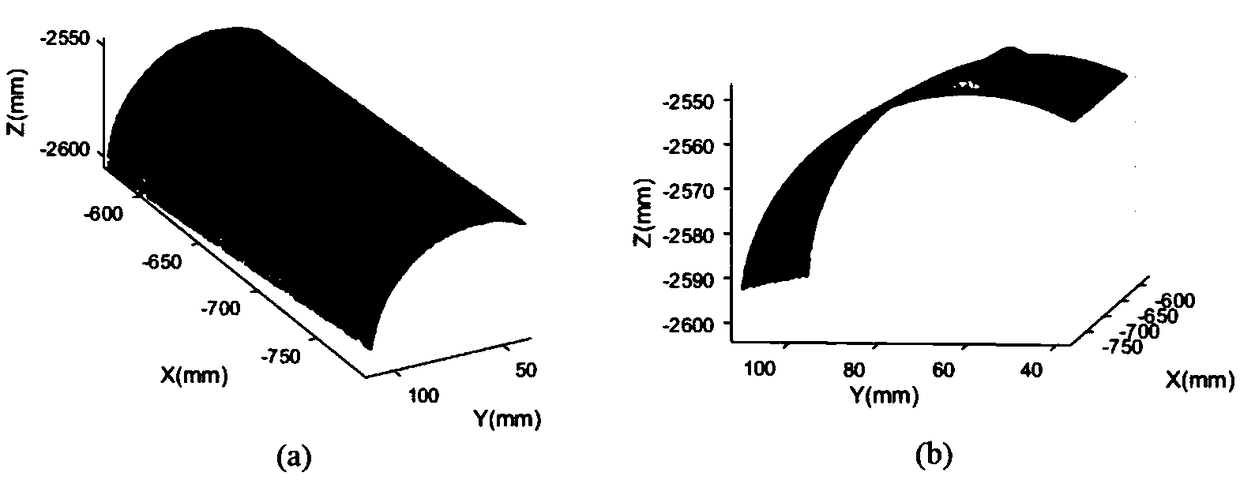

[0040] The present invention proposes a method for detecting the three-dimensional shape of a weld bead based on surface structured light. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

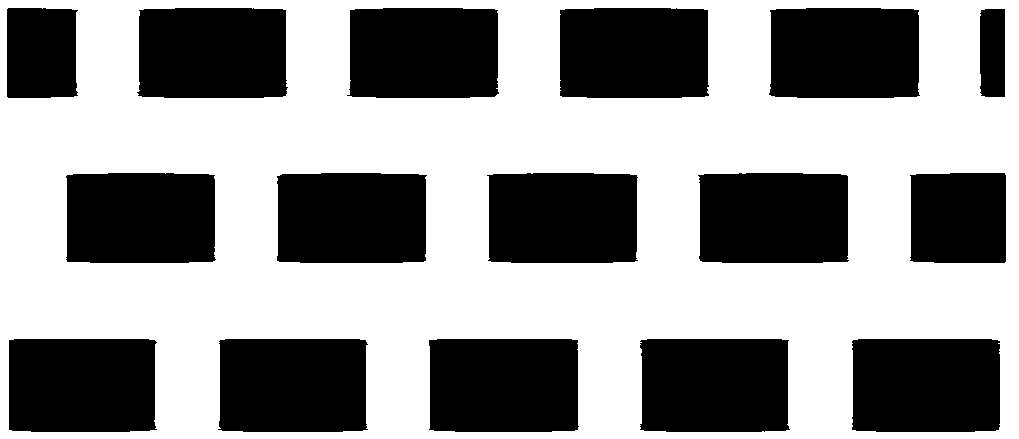

[0041] The invention proposes a method for detecting the three-dimensional shape of a weld bead based on surface structured light, which uses the principle of structured light to measure the three-dimensional shape of the weld bead surface, and separates the weld bead point cloud from the obtained point cloud data. The method includes the following steps:

[0042] (1) Build a structured light measurement system;

[0043] Choose projector (can be arbitrary model, present embodiment adopts Texas Instruments DLP LightCrafter 4500), camera (can be arbitrary model, present embodiment adopts GO-5000M-USB of Danish JAI company), connect projector, camera and to-be-tested The weld bead samples are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com