Differential pressure type steam dryness measurement instrument and calculation method

A calculation method, differential pressure technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of unsuitable real-time measuring instruments, loss, difficult to popularize and apply, etc., to achieve broad application and development prospects, fast dynamic response speed, continuous real-time Display and record powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

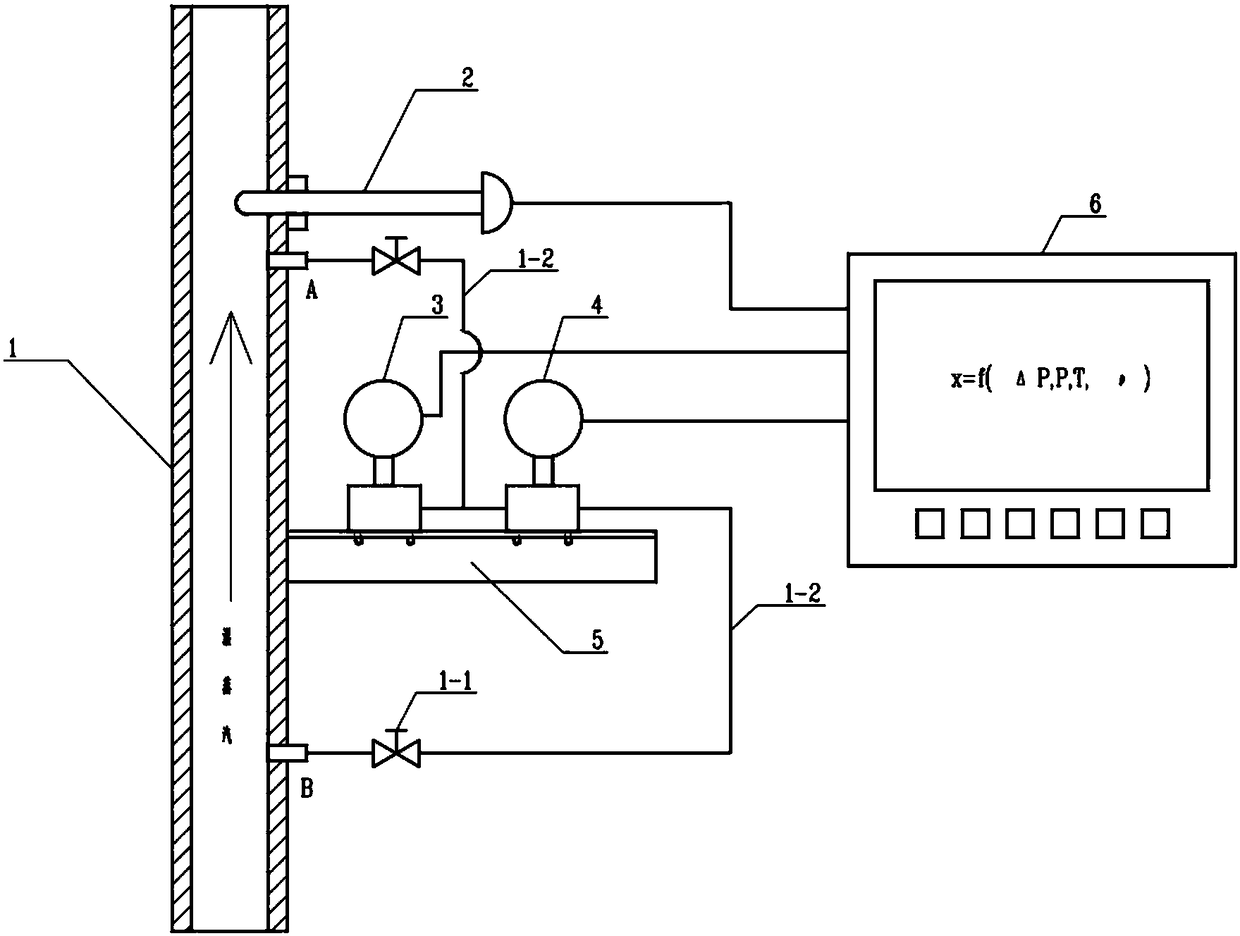

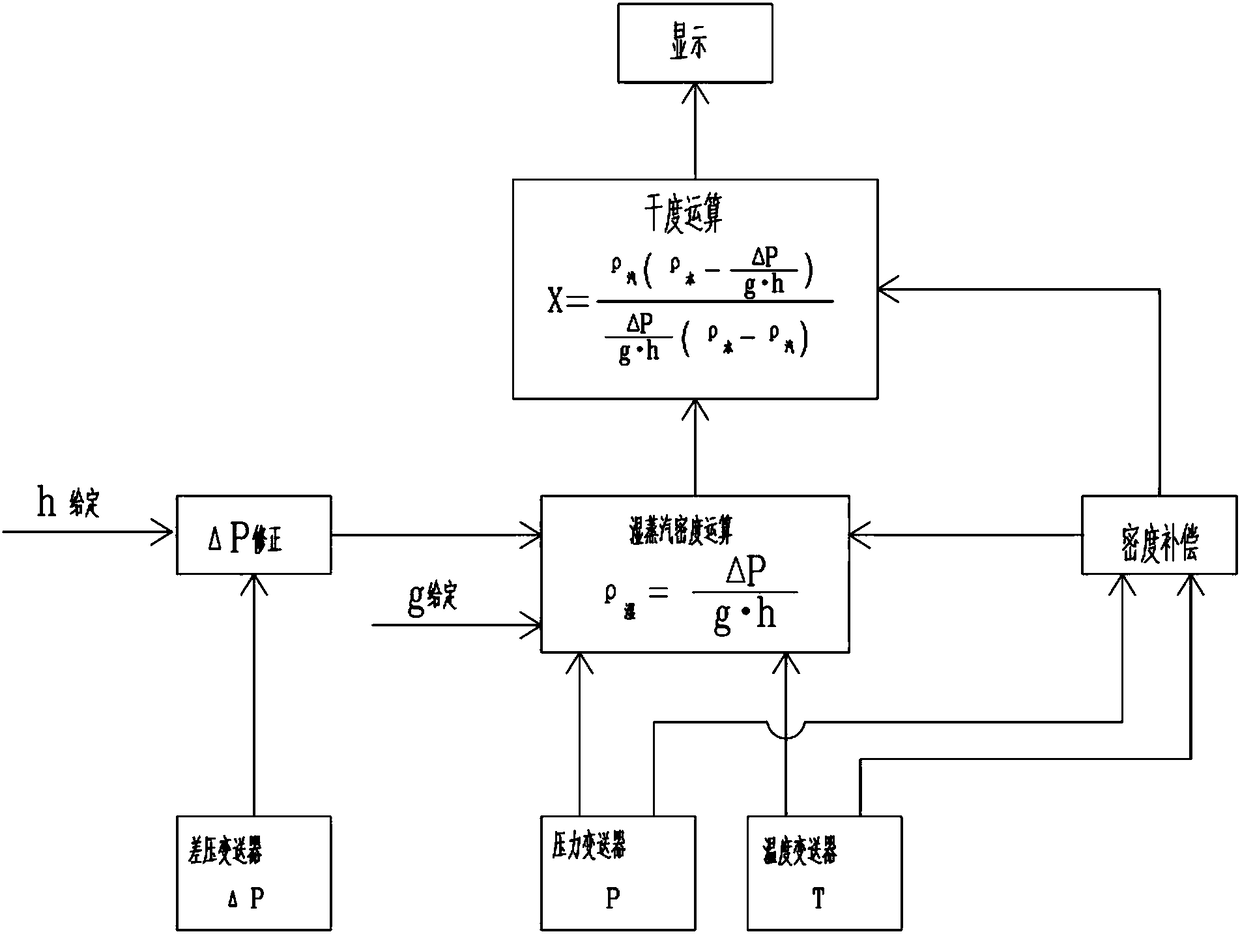

[0035] Such as figure 1 and figure 2 As shown, the specific embodiment one of the present invention includes a steam sampler 1, a temperature transmitter 2, a differential pressure transmitter 3, a pressure transmitter 4 and a dryness calculator 6, and the steam sampler 1 is respectively connected to Temperature transmitter 2, differential pressure transmitter 3 and pressure transmitter 4, steam sampler 1 is provided with high pressure A terminal and low pressure B terminal, and is connected to differential pressure transmitter 3, A terminal and B terminal are respectively provided with A cut-off needle valve 1-1, temperature transmitter 2, differential pressure transmitter 3, and pressure transmitter 4 respectively measure and convert changes in physical quantities of temperature, differential pressure, and pressure into standard electrical signals and transmit them to Dryness calculator 6 performs calculation;

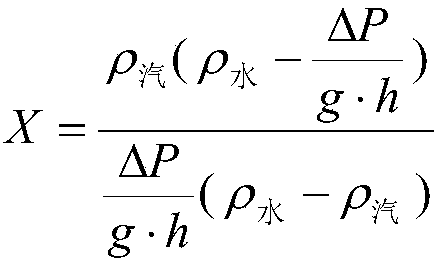

[0036] The steam dryness calculation method is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com