Direct-current contactor

A DC contactor and dynamic contact technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of low energy saving and high coil power consumption, and achieve the effects of convenient installation, low production cost, and reduced startup power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

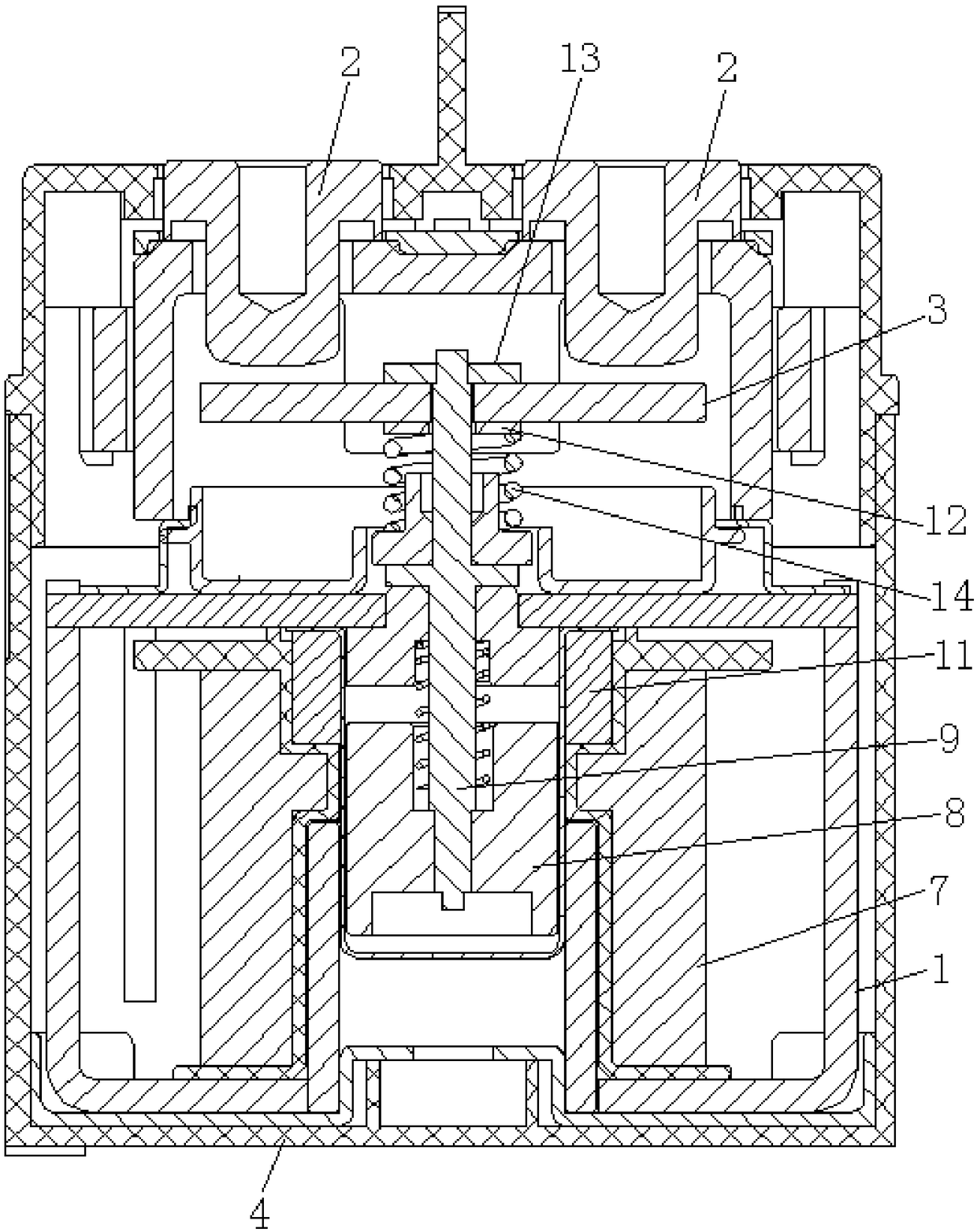

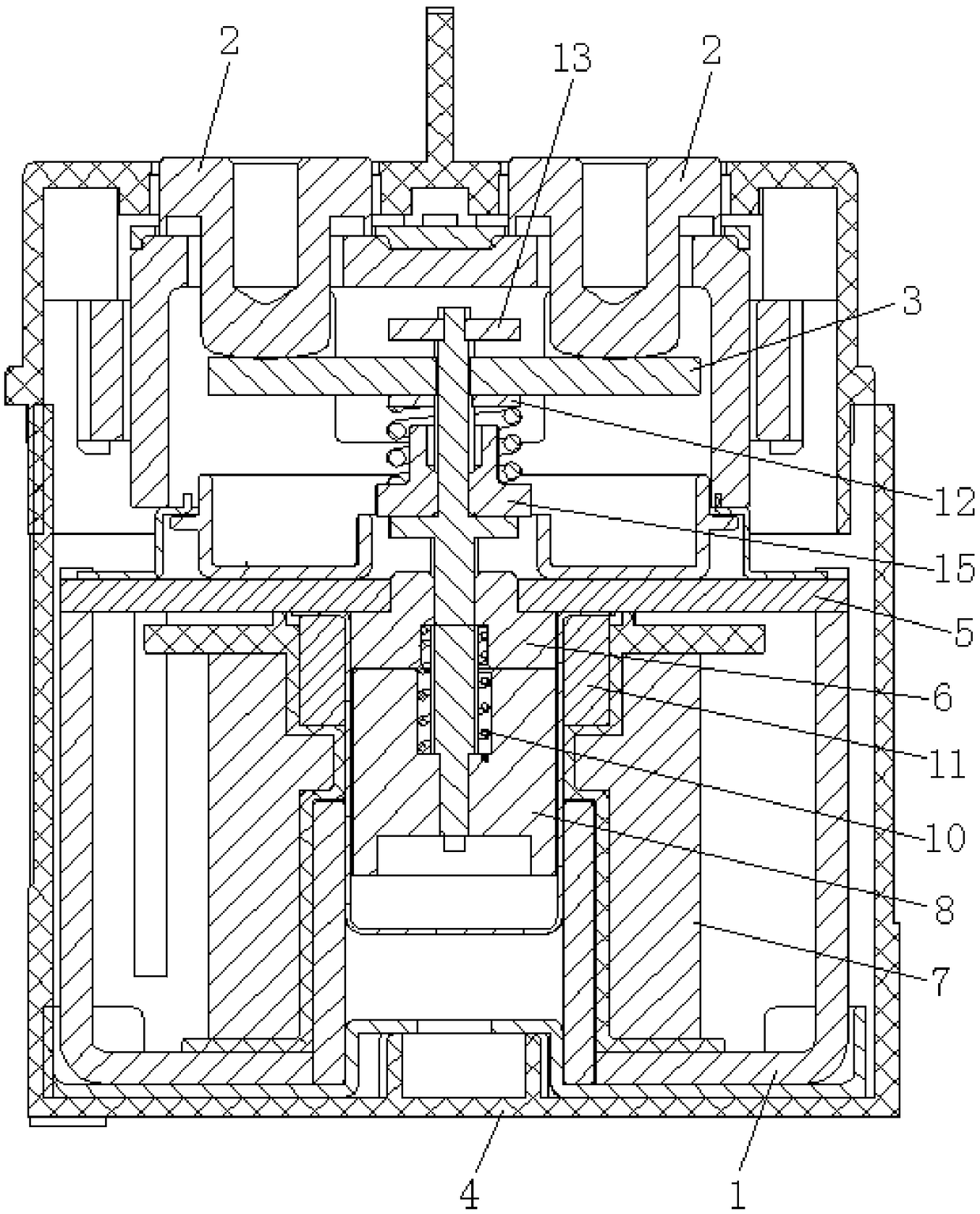

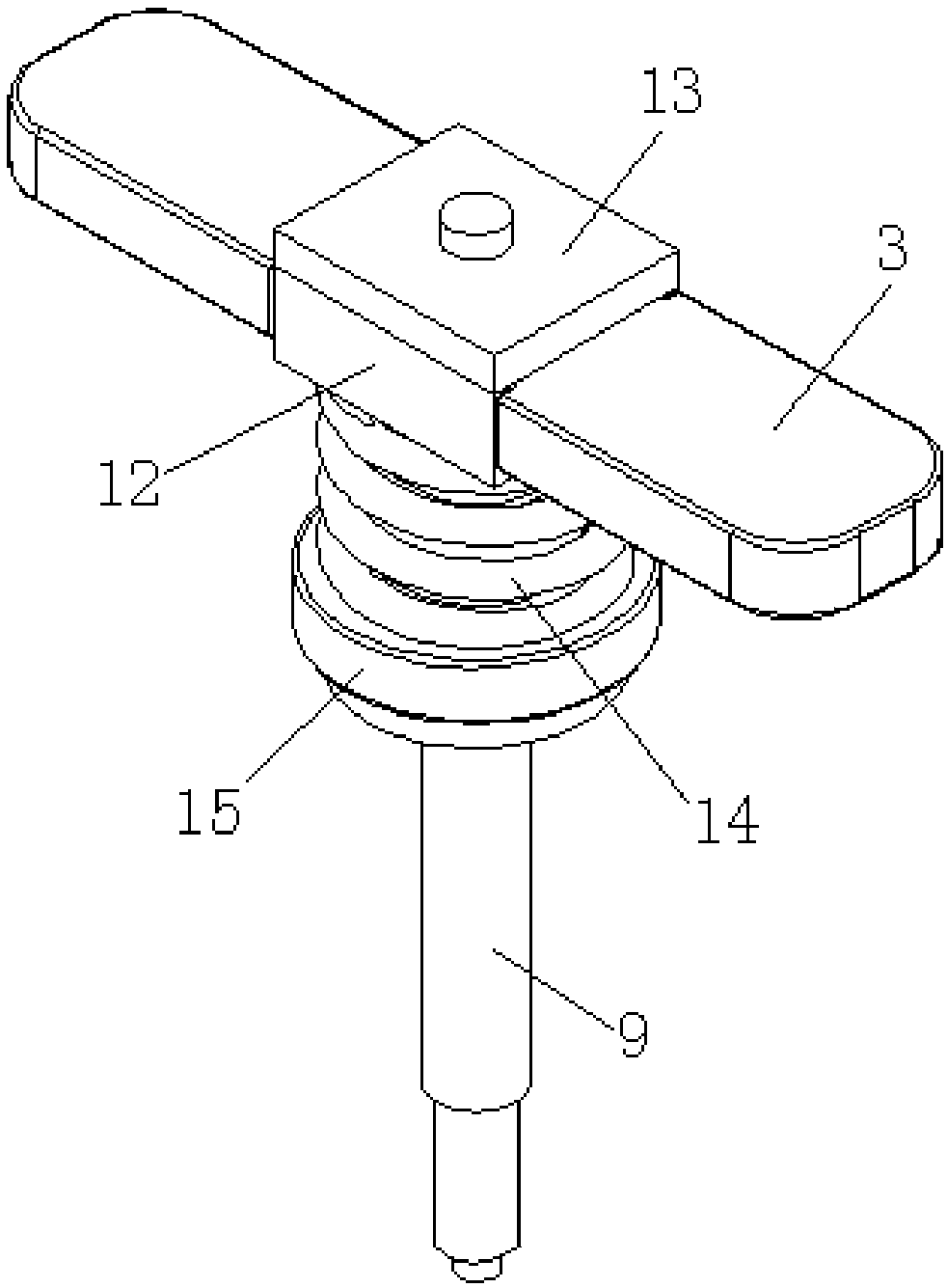

[0032] Please refer to the attached figure 1 And attached figure 2 As shown, they are schematic cross-sectional structural diagrams of the DC contactor in the present invention in the disconnected working state and the connected working state; the DC contactor includes a housing 1, two static contacts 2, a moving contact piece 3 and a driving mechanism, Wherein, an insulating shell 4 is fixedly sheathed outside the housing 1, and a diaphragm 5 is positioned and installed in the inner cavity of the housing 1, and the diaphragm 5 divides the inner cavity of the housing 1 Separated into an upper chamber and a lower chamber, and a static iron core 6 is positioned and installed on the diaphragm 5; the two static contacts 2 are arranged side by side in the upper chamber, and the moving contact piece 3 is also arranged in the upper chamber, and the moving contact piece 3 is arranged vertically opposite to the two static contacts 2 respectively; the driving mechanism has a coil 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com