Impulse wheel of fan coal grinding mill using casting-forging welding device

A technology of fan coal pulverizer and welding structure, which is applied in grain processing and other directions, can solve the problems of difficulty in realizing the casting quality of large-diameter roulettes, unable to guarantee the casting quality 100%, and difficult to realize large-diameter roulettes, etc., and shorten the idle running time. , the effect of light weight and shortened start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

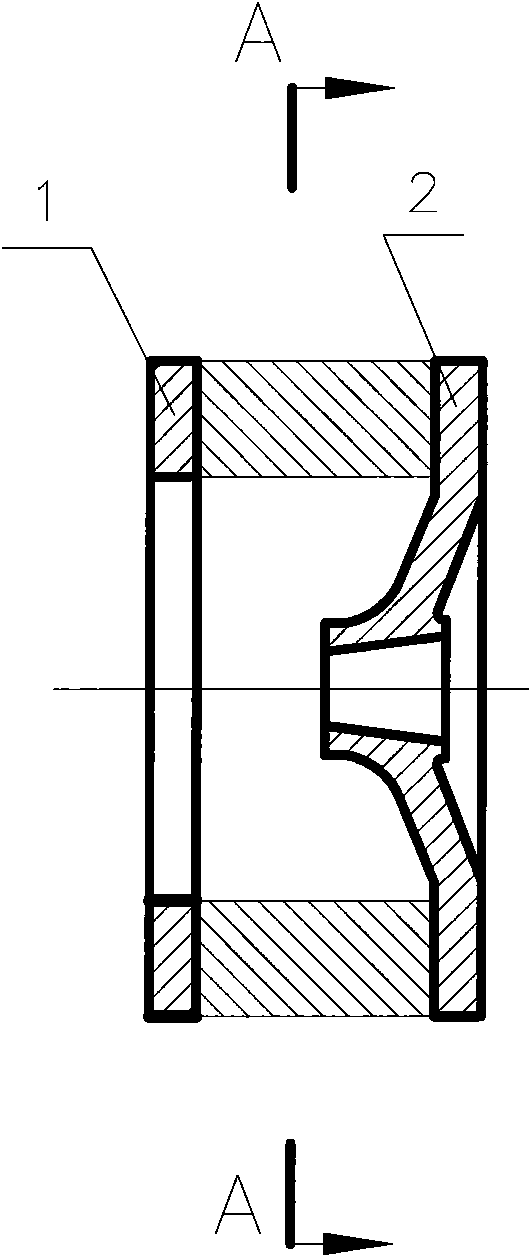

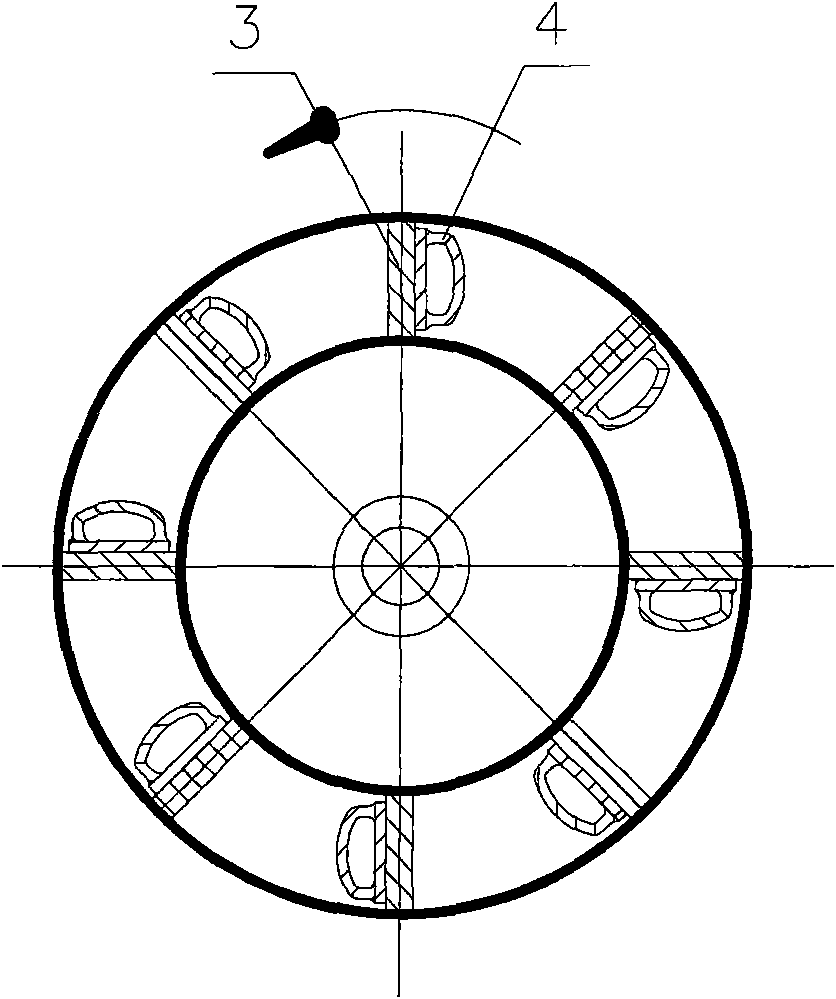

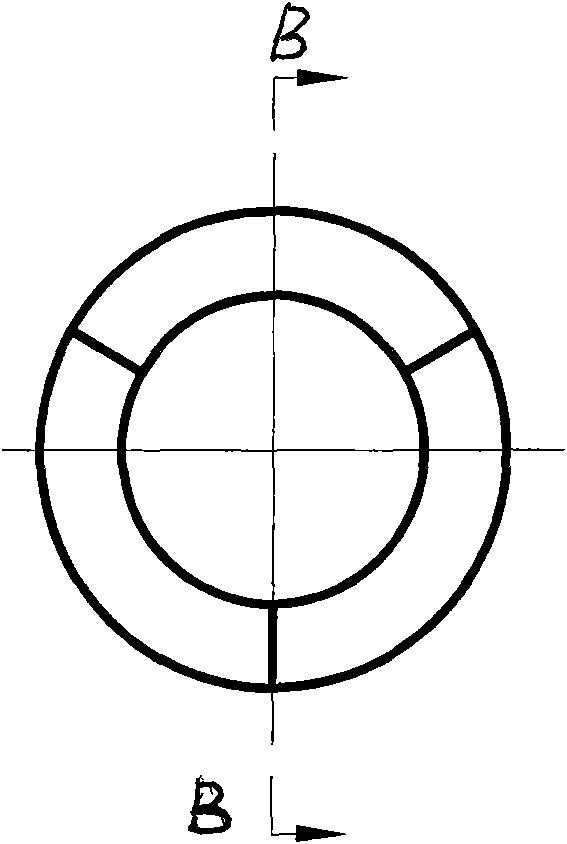

[0014] Referring to the accompanying drawings, a fan coal mill impact wheel adopts cast forging and welding structure. The whole device is composed of front plate 1, rear plate 2, striking plate 3, and connecting beam 4. Connected together, the strike plate 3 is installed on the connecting beam 4; the front plate 1 is welded with three forged steel plates; the rear plate 2 is welded with three forged steel plates, and then welded with the cast hub; the front plate 1 The material is 9NiMo5, the disc material of the rear disc 2 is 9NiMo5, and the hub material is ZG20MnV; the material 9NiMo5, at a temperature of 350°C, the material strength value σs=335MPa; the material ZG20MnV, at a temperature of 350°C, the material strength value σs =220MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com