Solid mushroom strain transferring cultivation machine for edible mushroom stick transferring cultivation and transferring cultivation method

A technology for inoculating solid bacteria and bacteria sticks, which is applied in botany equipment and methods, applications, horticulture, etc., can solve the problems of poor consistency of bacteria in the bag, uneven size of bacteria blocks, and high labor intensity of workers. Reduce production costs, simple and ingenious structure, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

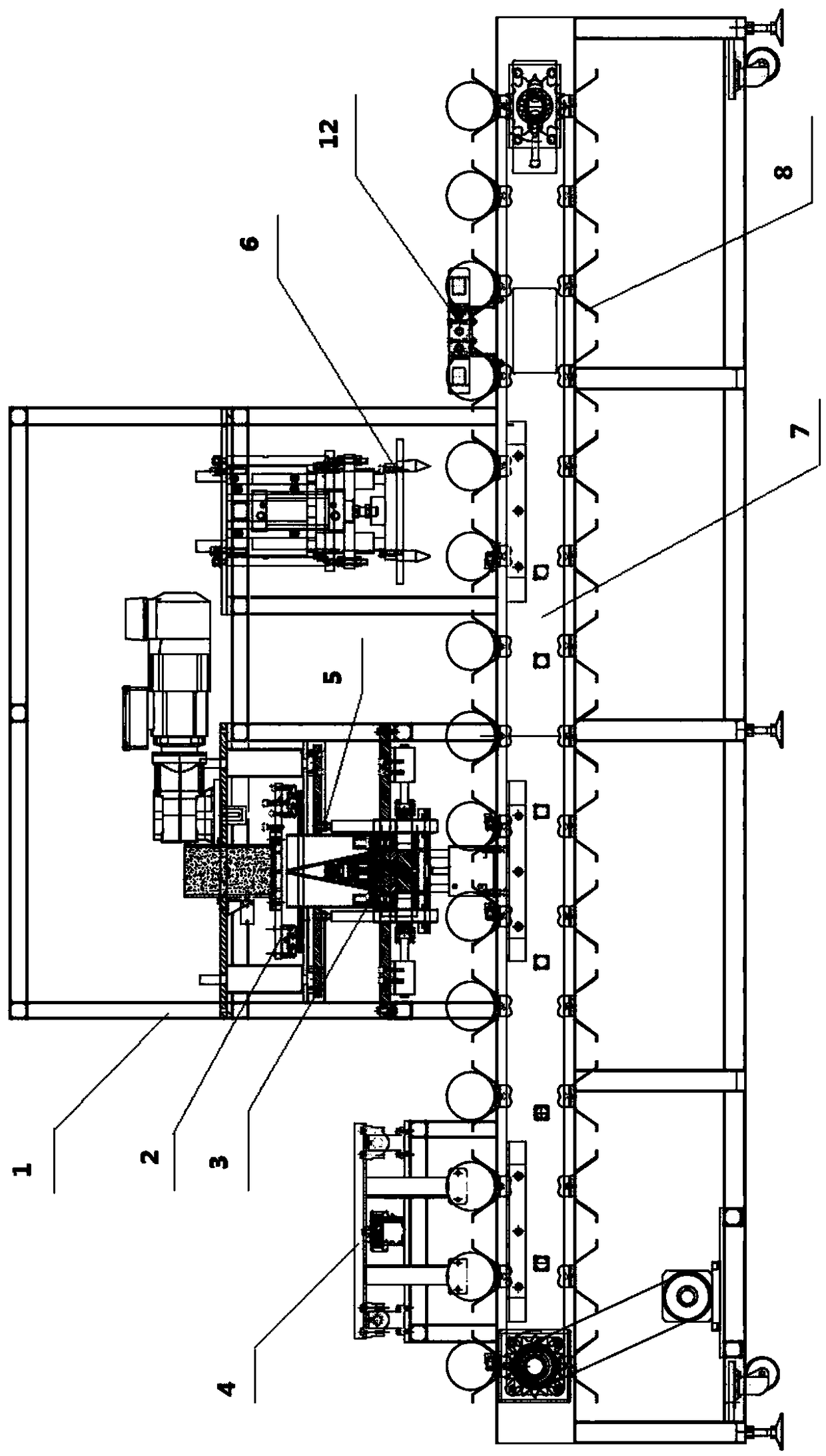

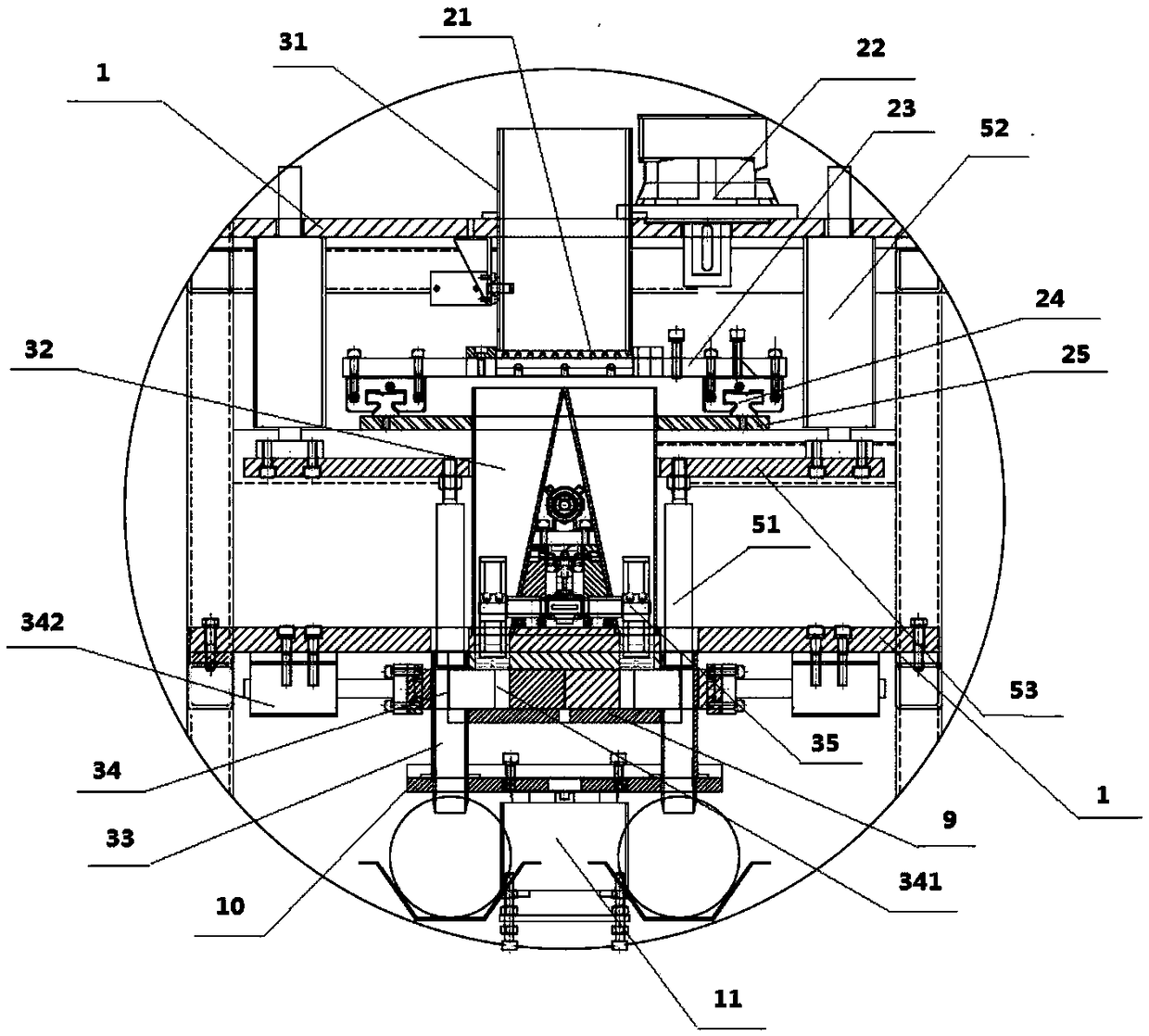

[0038] Example 1, reference figure 1 , figure 2 , A solid strain inoculation machine suitable for inoculation of edible fungus sticks, including:

[0039] The strain scraping mechanism 2 includes a scraper 21 and a scraping power mechanism 22 that drives the scraper 21 to reciprocate;

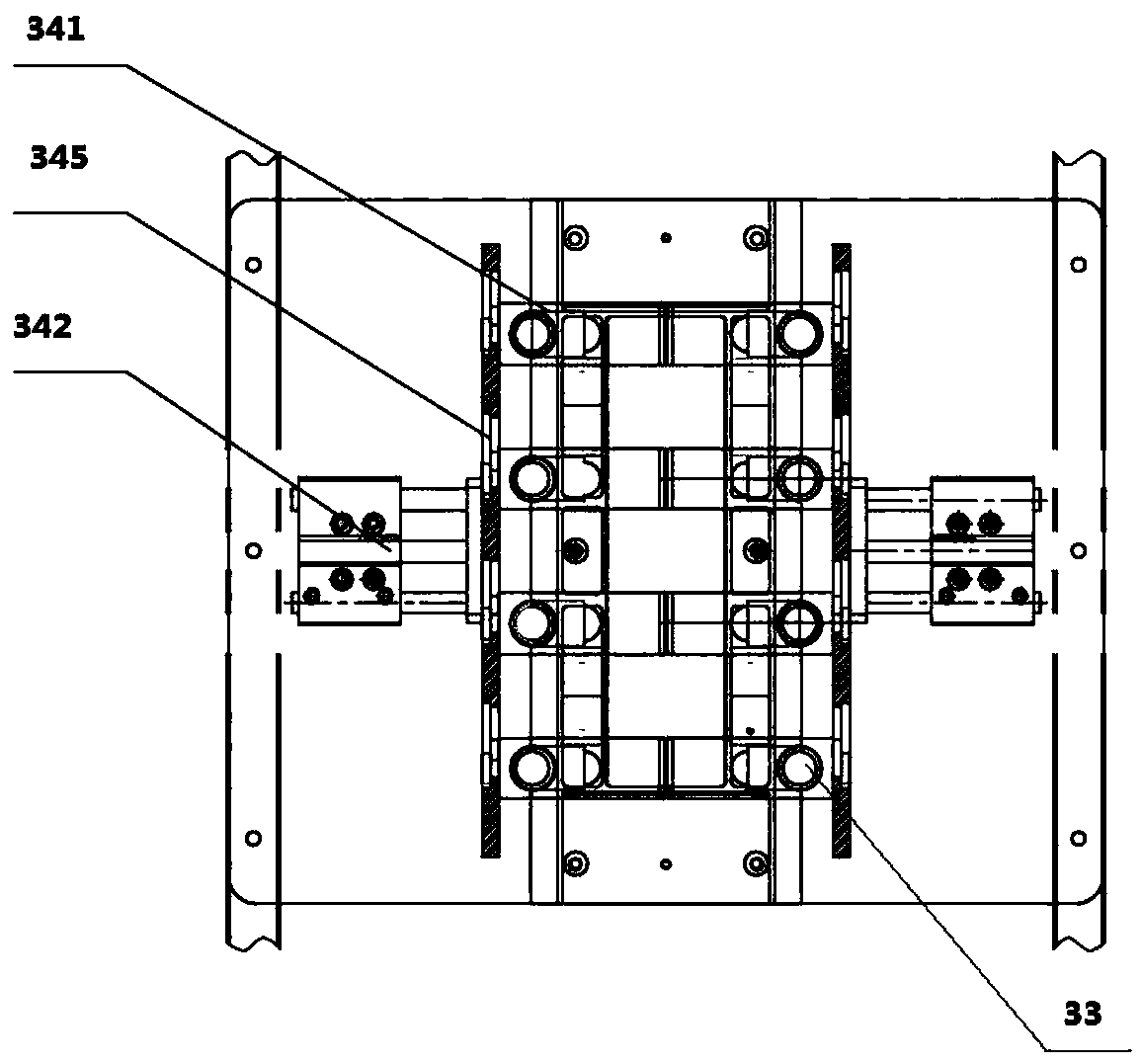

[0040] The strain feeding mechanism 3 includes a strain tube 31, a strain bin 32, a feeding tube 33, and a quantitative mechanism 34; the strain tube 31 and the strain bin 32 are respectively installed on the frame 1 above and below the scraper 21; The quantification mechanism 34 includes a quantifier 341 and a quantification power mechanism 342 that drives the quantifier 341. The quantifier 341 is provided under the discharge port of the bacterial seed bin 32. The quantifier 341 is provided with a feeding tube 33 for supporting passage and holding bacteria. The quantitative trough 343 of the seed and the blocking block 344 matched with the discharge port of the bacterial seed bin. The bottom of th...

Example Embodiment

[0043] Example 2, the solid strain inoculation machine suitable for inoculation of edible fungus sticks as described in Example 1: Refer to Figure 5 with 6 The fixed strain inoculation machine is also provided with a shifting mechanism 35. The shifting mechanism 35 includes a shifting lever 351 arranged in the lower part of the strain storage 32. The shifting lever 351 is connected to the shifting lever power mechanism 352 directly or through a transmission mechanism.

Example Embodiment

[0044] Example 3, reference Image 6 In the solid strain inoculation machine suitable for inoculation of edible fungus sticks described in Example 2: The shifting lever power mechanism 352 is a shifting cylinder, and the power output end of the shifting cylinder is equipped with a rack 353. The bar 353 is fixed on the rack slide 354, the rack slide 354 runs in the slider, and the slider is installed on the frame 1. The shift lever 351 is installed on the pinion shaft 355, the rack 353 and the pinion shaft 355 are geared Engaged, driving the lever 351 to rotate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap