A low noise pulping method of a food processing machine

A food processing machine and food processing technology, applied in non-electric variable control, control/regulation systems, and simultaneous control of multiple variables, etc., can solve problems such as noise, overflow or poor crushing, and reduce beating noise and prevent overflow. Risk, avoid the effect of excessive crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

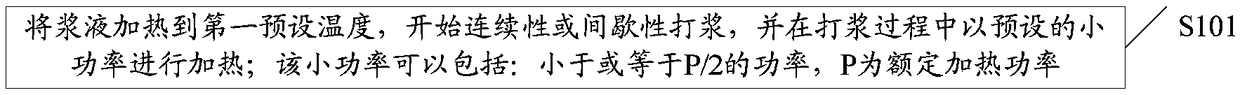

[0059] Embodiments of the present invention provide a low-noise pulping method for a food processor, such as figure 1 As shown, the method may include S101:

[0060] S101. Heating the slurry to a first preset temperature, starting continuous or intermittent beating, and heating with a preset low power during the beating process; the low power may include: power less than or equal to P / 2, P is the rated heating power.

[0061] In the embodiment of the present invention, since the current pulping process cannot take into account pulping noise, slurry overflow and pulping effect, the embodiment of the present invention proposes a low-noise pulping method for a food processor, which can Continuous or intermittent beating is carried out according to different pulping stages to ensure the pulping effect and reduce the pulping noise; in the beating process, it can be supplemented with low-power heating, so as to prevent the pulp from overflowing due to excessive power, and can Make...

Embodiment 2

[0063] On the basis of Example 1, this example provides a specific implementation of the preheating stage of the embodiment scheme of the present invention when the food processing flow includes a preheating stage.

[0064] Optionally, the food processing process of the food processor may include: a pre-heating stage; the pre-heating stage is used to heat the slurry from room temperature to a preset temperature value.

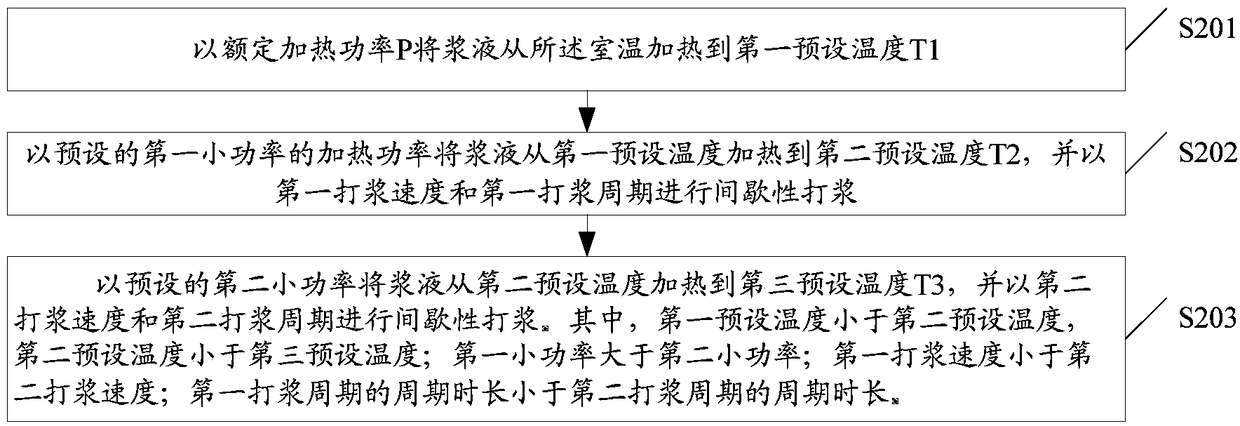

[0065] Optionally, as in figure 2 As shown, heating the slurry to a first preset temperature, starting continuous or intermittent beating, and heating at a preset low power during the beating process may include S201-S203:

[0066] S201, heating the slurry from the room temperature to a first preset temperature T1 with a rated heating power P.

[0067] In the embodiment of the present invention, the first preset temperature T1 may satisfy: 75°C<=T1<=80°C.

[0068] In the embodiment of the present invention, in the initial heating stage of the preheating stag...

Embodiment 3

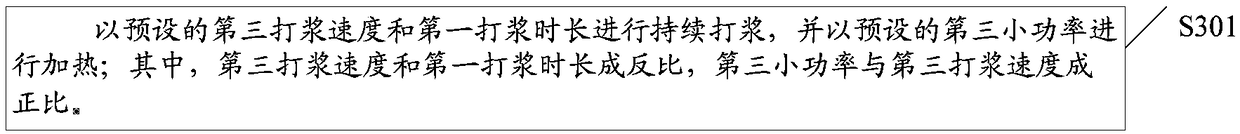

[0084] This embodiment is based on the second embodiment, in order to prevent overflow caused by too long heating time, the second low power (the power of low power heating can be set to 1 / 3P to 1 / 4P,) the heating time can be based on A specific implementation method of limiting different capacities (or material quantities).

[0085] In the embodiment of the present invention, taking a 1000W heating tube, a 130W motor, and 1300ml of material as an example, assuming a temperature rise of 5°C from T2 to T3, the total absorbed energy of the material is C*m*ΔT=4200*1.3*5=27300J , the total heating energy provided by the power supply is U*I*t*η, the stirring speed of the 130W motor is 15W, the heating efficiency is 0.8, and the motor is stirred for 3s and stopped for 3s, then (1000*t / 3+15*t / 2) *0.8=27300, t=100s can be obtained, that is, the heating time of the second low power can be limited to 100s. It can be seen that the amount of material is proportional to the second low pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com