A dregs-free food processor

A technology for food processing machines and grinding surfaces, which is applied in kitchen utensils, home utensils, applications, etc., and can solve the problems of motor shaft movement, inability to achieve filter-free and slag-free, delicate taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

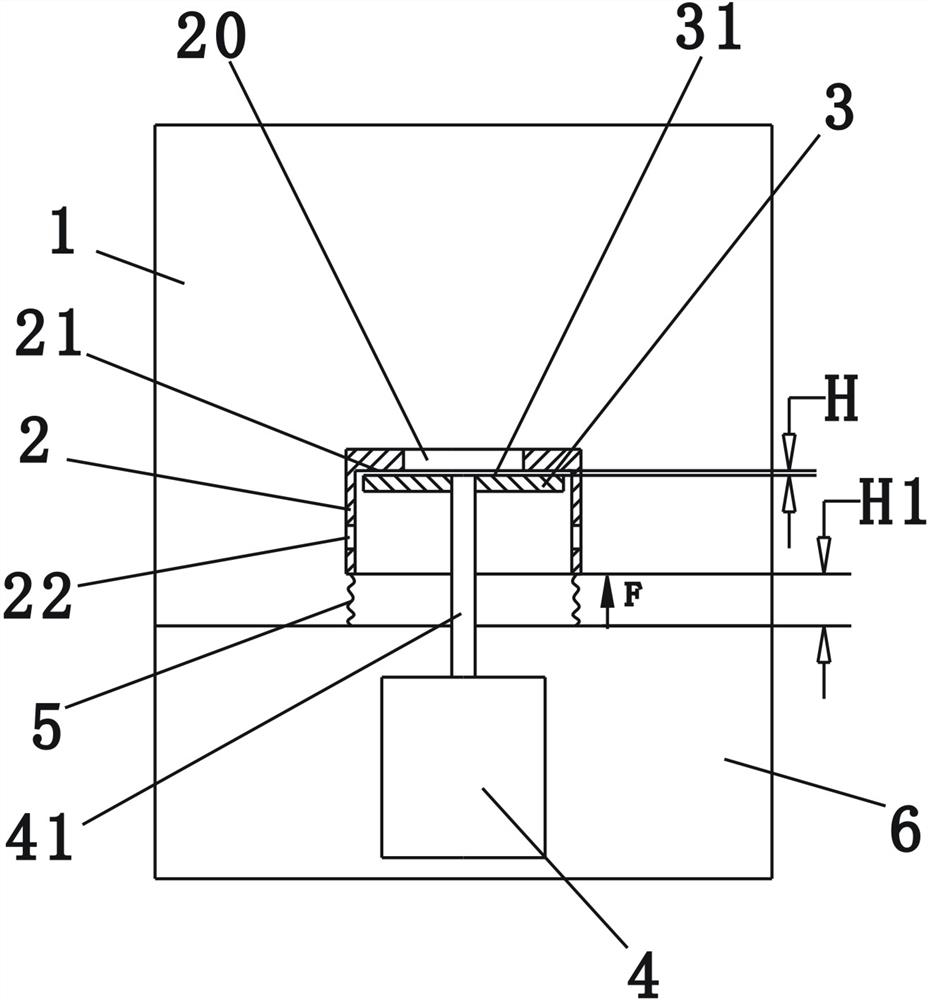

[0048] Such as figure 1 Shown is a schematic structural diagram of the first embodiment of the present invention. A slag-free food processor, comprising a cup body 1 and a grinding device arranged in the cup body 1, the grinding device includes a grinding cover 2 installed at the bottom of the cup body 1, driven by a rotating shaft 41 and arranged in the grinding cover 2 The rotating grinding disc 3 and the tightening device 5, the grinding cover 2 has a first grinding surface 21 towards the bottom of the cup, and the rear end of the grinding cover 2 has an opening 20 passing through the first grinding surface, and the rotating grinding disc 3 has a The first grinding surface 21 cooperates to form the second grinding surface 31 of plane grinding, and the said tightening device 5 has a downward tensioning force F to the grinding cover 2, so that the first grinding surface 21 is tightened on the second grinding surface 31 , located below the first grinding surface 21, the perip...

Embodiment 2

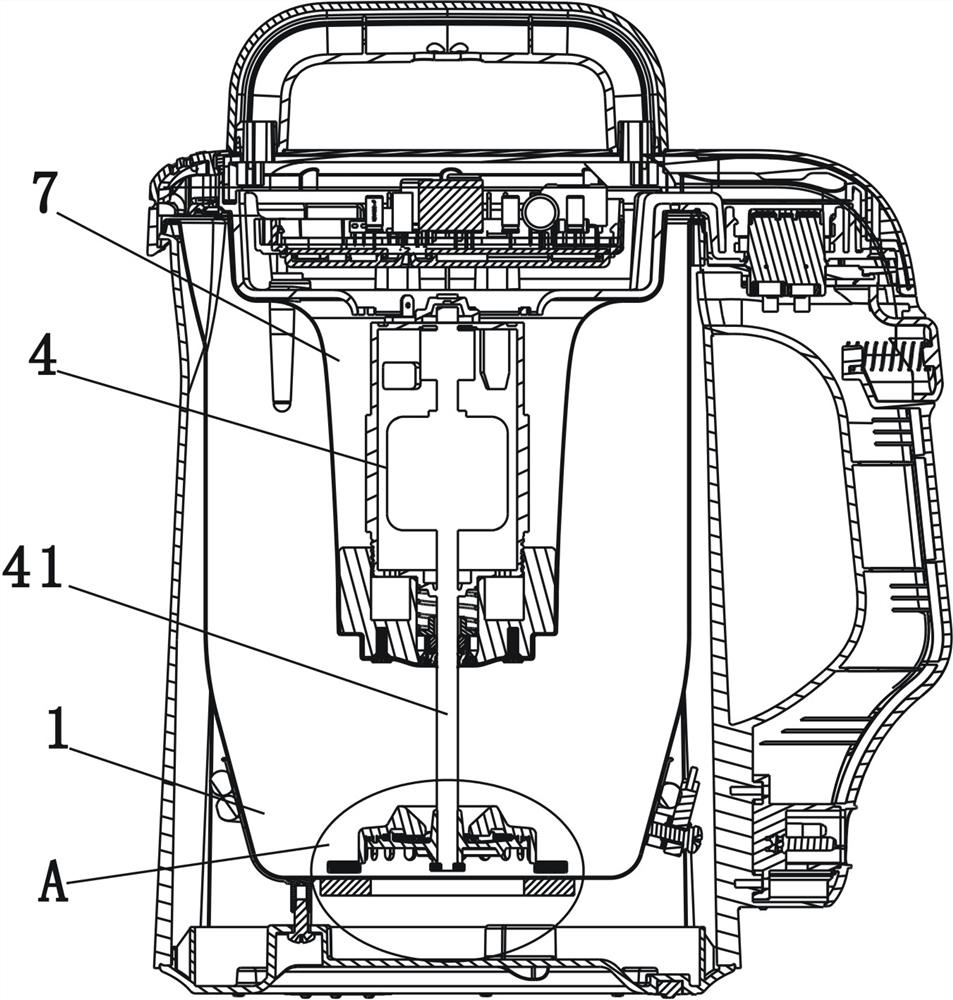

[0057] Such as figure 2 , image 3 , Figure 4 Shown is a schematic structural diagram of the second embodiment of the present invention. A soybean milk machine, comprising a machine head 7 and a cup body 1, a motor 4 is installed in the machine head, and a rotating shaft 41 driven by the motor penetrates the bottom of the machine head 7 and extends into the cup body, and the front end of the rotating shaft 41 is fixed with a rotating grinding disc through a nut 42 3. The grinding cover 2 is set on the outside of the rotating grinding table 3, the grinding cover 2 has a first grinding surface 21 towards the bottom of the cup, and the rotating grinding table 3 has a second grinding surface 31 corresponding to the first grinding surface 21 to form a plane grinding, And the grinding cover 2 is supported on the rotating shaft 41 by the rotating grinding disc 3 .

[0058] Simultaneously, the soya-bean milk maker of this embodiment also has a tightening device that makes the gri...

Embodiment 3

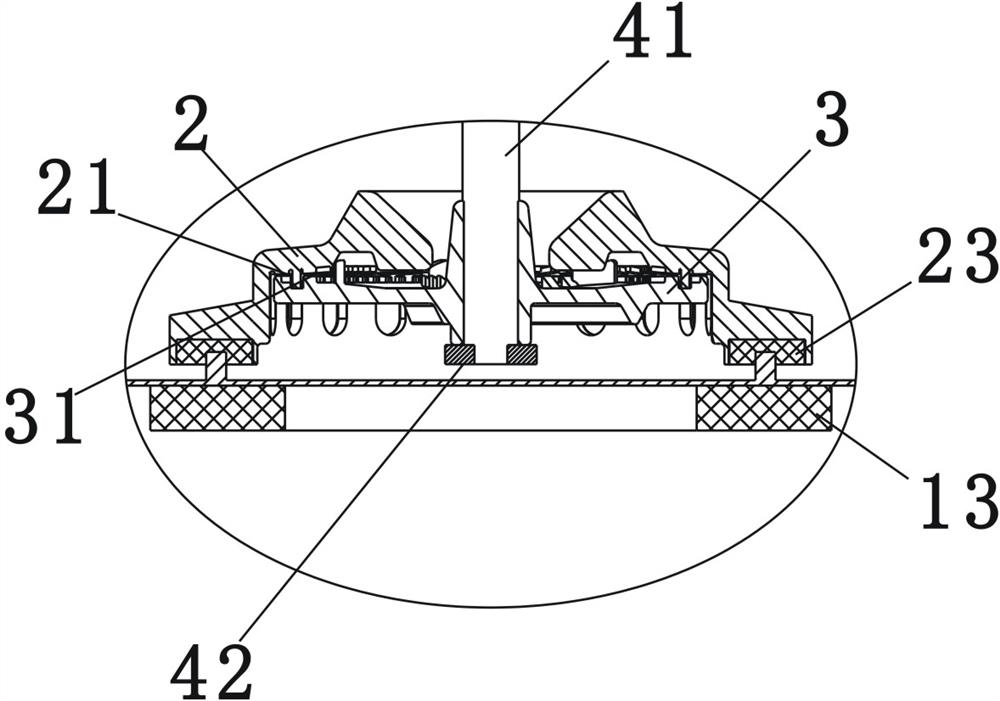

[0062] Such as Figure 5 , Figure 6 , Figure 7 , Figure 8 Shown is a schematic structural view of the third embodiment of the present invention. This embodiment is an improvement made on the basis of Embodiment 1. The difference from Embodiment 1 is that in this embodiment, the grinding cover 2 is installed on the mounting part at the bottom of the cup body 1, and the mounting part is a detachable mounting platform 11 relative to the cup body 1. In this embodiment, the tightening The device comprises a first magnetic part 23 arranged at the front end of the grinding cover 2 and a second magnetic part 13 arranged on the mounting table 11, the first magnetic part 23 and the second magnetic part 13 magnetically cooperate, and the grinding cover 2 Through the magnetic attraction between the first magnetic part 23 and the second magnetic part 13, the first grinding surface is tightened to the second grinding surface.

[0063] In this embodiment, the mounting table 11 has an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com