Pulping method of food processor

A food cooking machine and pulping technology, which is applied in kitchen utensils, home utensils, applications, etc., can solve the problems of low soybean utilization rate, poor flavor, and reduced solubility of soybean milk protein, so as to increase the probability of contact and accelerate exchange , the effect of reducing the average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

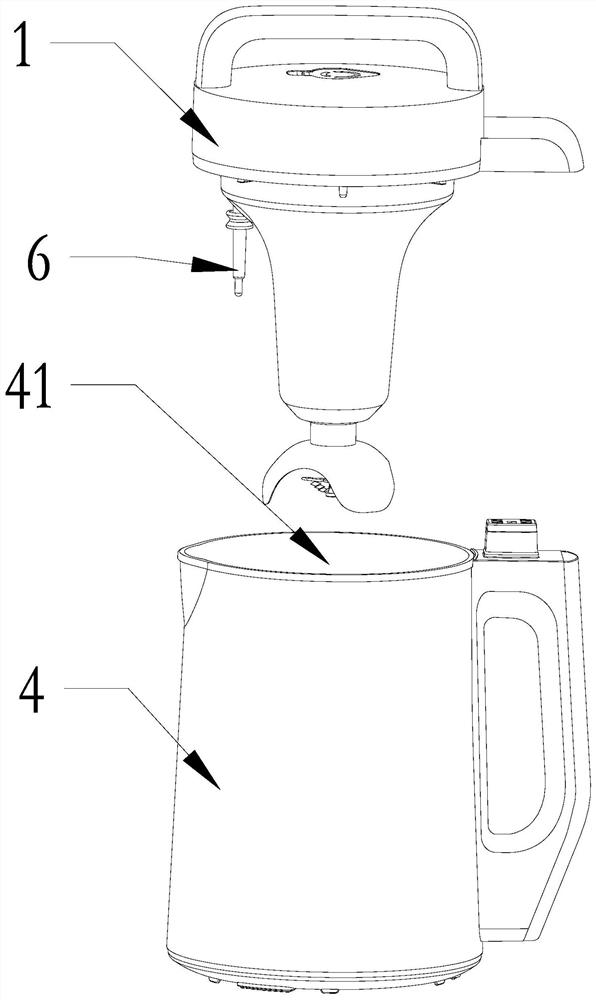

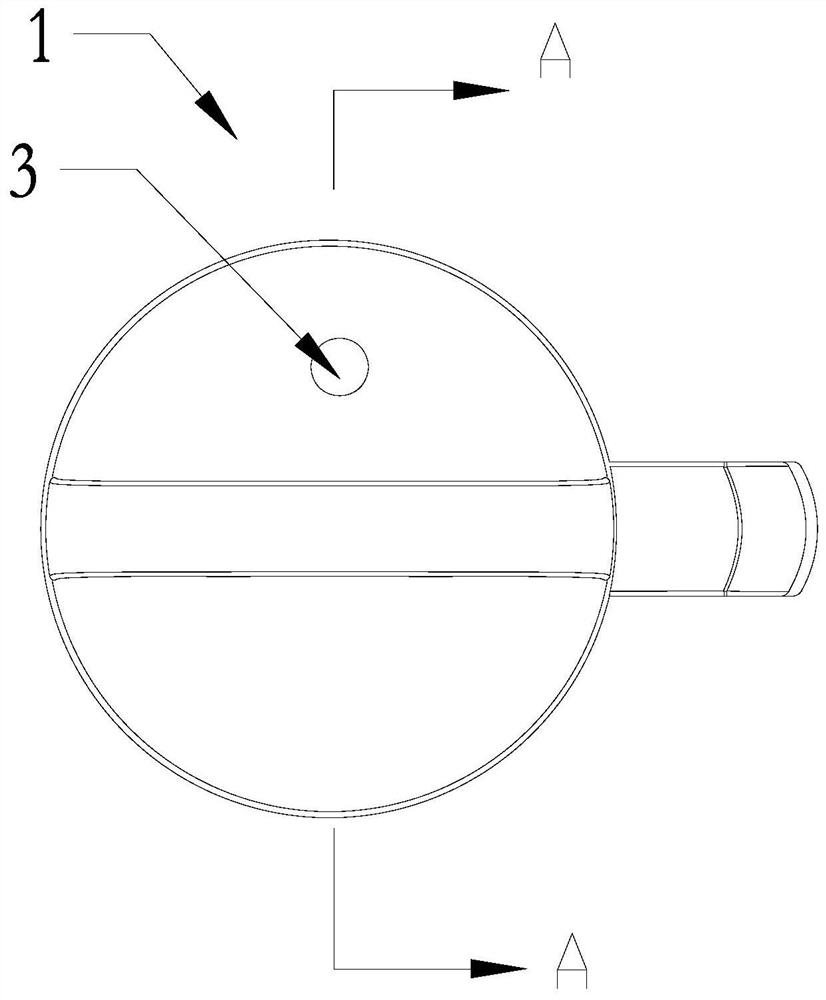

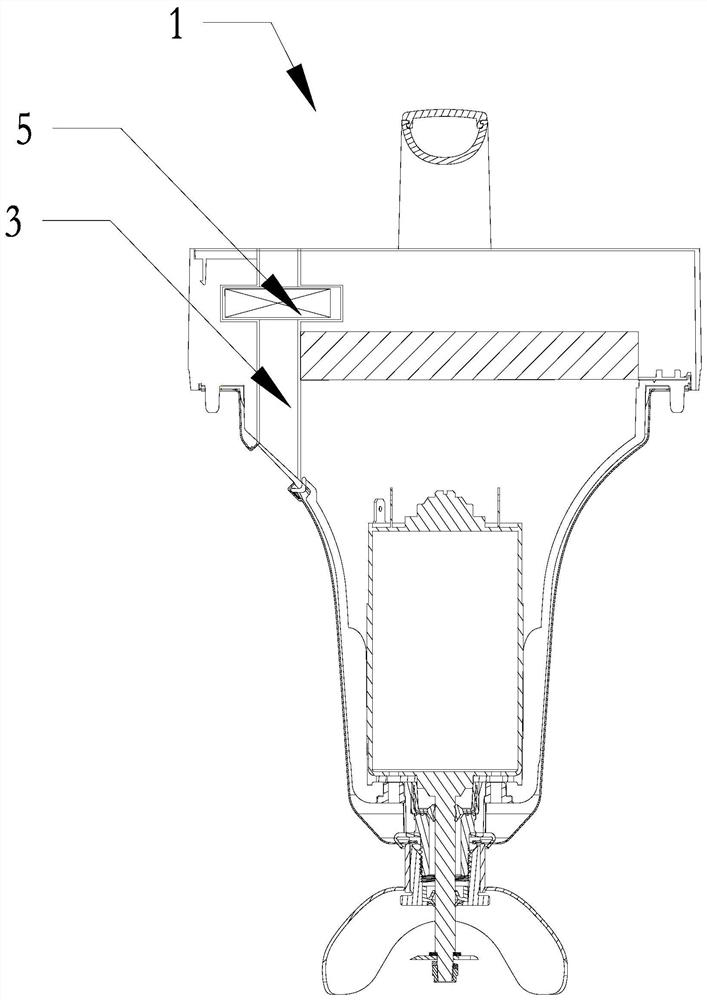

[0032] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0033] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0034] In the present invention, unless otherwise stated, the directional words used such as "upper, lower, top, bottom" are usually for the direction shown in the drawings or for the vertical, vertical or gravity direction The words used to describe the mutual positional relationship of the components mentioned above.

[0035] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

[0036] In order to improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com