A kind of preparation method of highly dispersed carbon-supported pt-ni catalyst

A high-dispersion, catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Energy saving, harsh reaction conditions and other issues, to achieve the effect of small particle size, low production cost, and improved agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

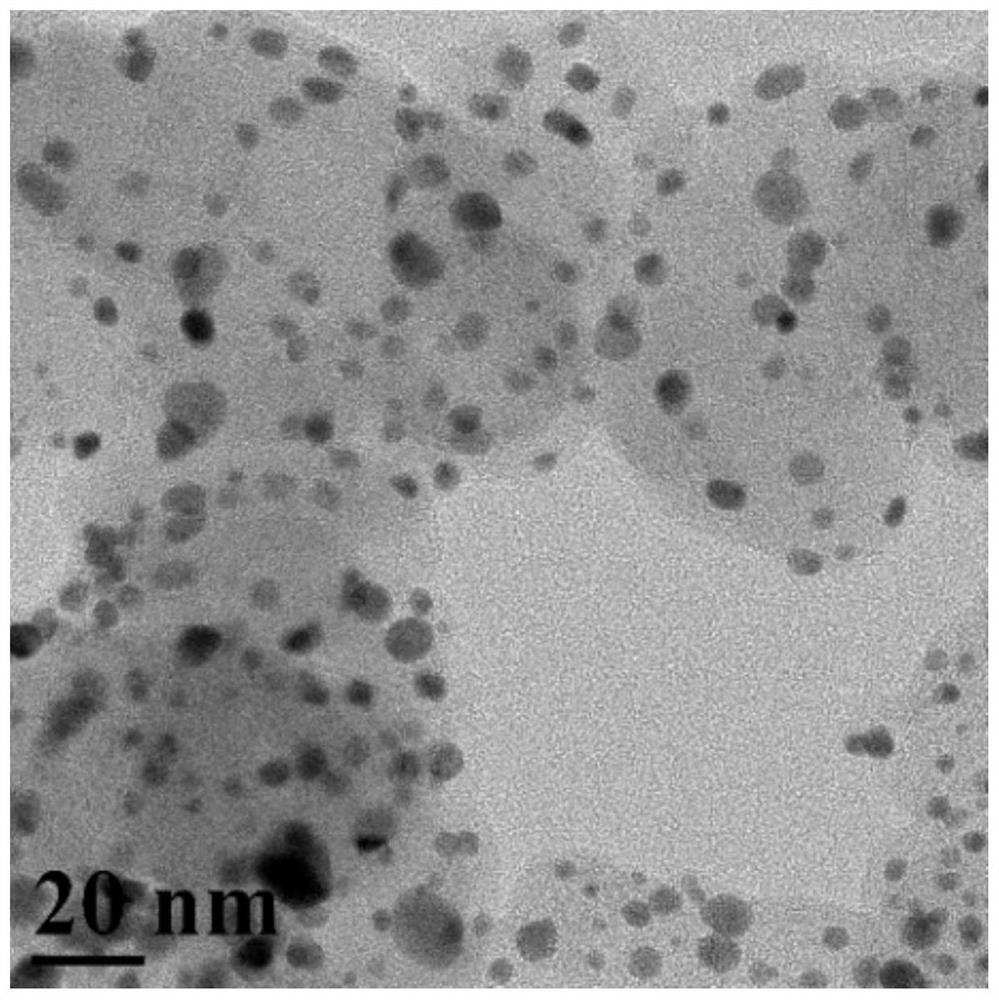

[0031] Pt 2 Ni / C catalyst (Pt:Ni molar ratio 2:1, mass accounts for 30% of catalyst total mass), takes by weighing the carbon powder slurry that is equivalent to 0.4gvulcan XC-72 carbon powder after ultrasonic and stress shear treatment, according to The above steps are followed by adding 0.7gNaCO 3 Adjust the pH to 8, and under magnetic stirring, mix 6.6 ml of 0.1158 mol / L chloroplatinic acid solution, 3.3 ml of nickel nitrate solution of the same concentration, and 1.5 g of formaldehyde solution (preparation method: add 14 ml of each 1 ml of formaldehyde solution to Diluted with deionized water) slowly drop into the slurry one by one, and stir evenly, control the reaction temperature to react at 75°C. After filtering and cleaning, at 550°C, a mixed gas of hydrogen and nitrogen (H 2 :N 2 =1:4) heat treatment for 5h to get 30%Pt 2 Ni / C catalyst. The catalyst was tested by TEM ( figure 1 ) and electrochemical characterization (Table 1), figure 1 It can be seen that the c...

Embodiment 2

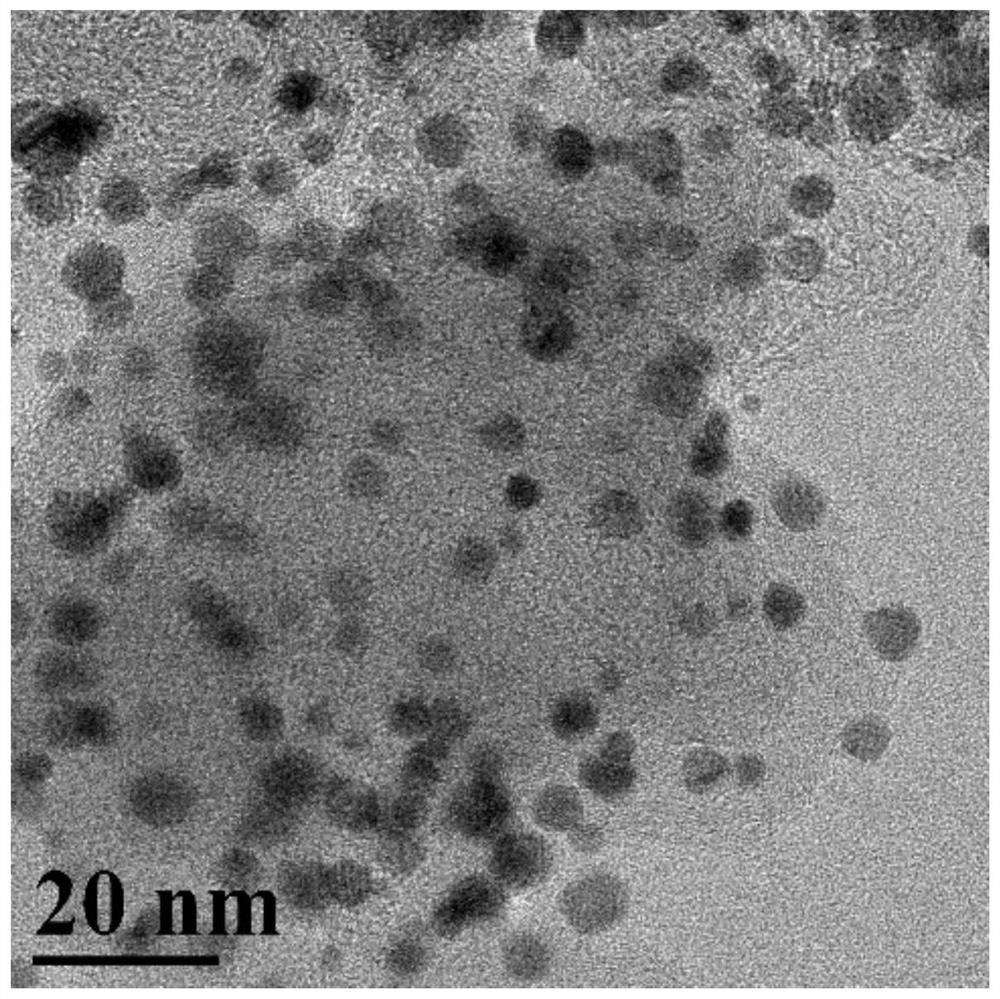

[0033] Change the Pt and Ni mol ratio among the embodiment 1, prepare PtNi / C catalyst (Pt:Ni mol ratio 1:1, quality accounts for 30% of catalyst total mass), take by weighing the equivalent through stress shearing of 0.35g Ketjen black carbon powder After cutting and crushing the carbon powder slurry, add 0.7g NaHCO successively according to the above steps 3 Adjust the pH to 8, and under magnetic stirring, mix 5.8267ml of 0.1158mol / L chloroplatinic acid solution, 5.8267ml of the same concentration of nickel nitrate solution, and 1.5g of formaldehyde solution (preparation method: add 14ml of each 1ml of formaldehyde solution to Diluted with deionized water) slowly drop into the slurry one by one, and stir evenly, control the reaction temperature to react at 80°C. After filtering and cleaning, at 500°C, a mixed gas of hydrogen and nitrogen (H 2 :N 2 =1:19) was heat-treated for 5 hours to obtain a 30% PtNi / C catalyst. The catalyst was tested by TEM ( figure 2 ) and electroc...

Embodiment 3

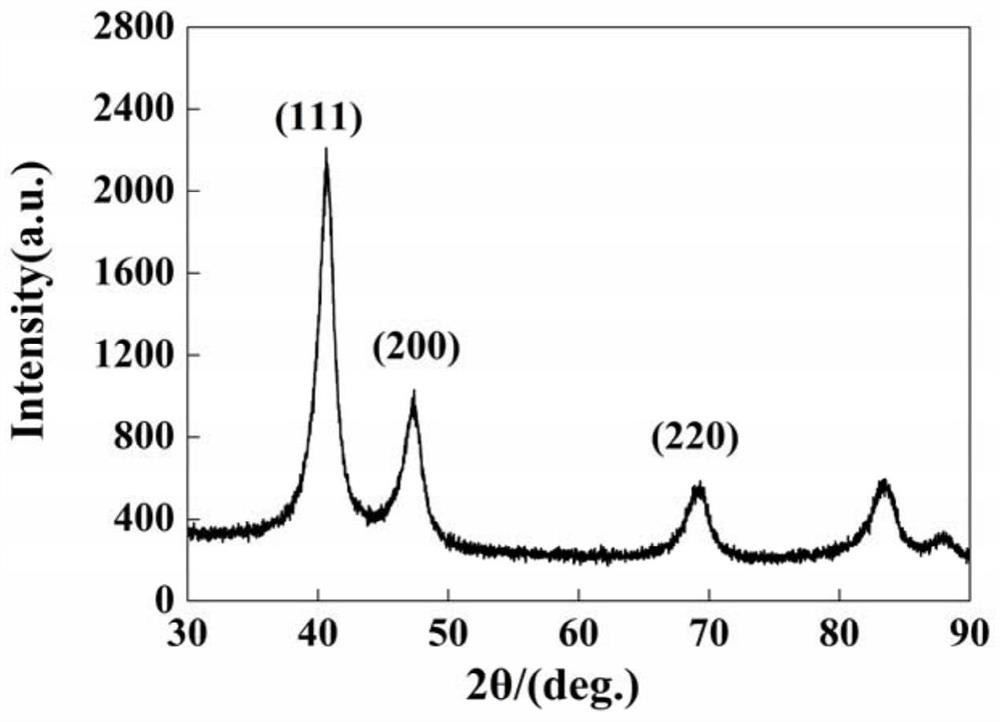

[0035] Change Pt and Ni mol ratio among the embodiment 1, prepare Pt 3 Ni / C catalyst (Pt:Ni molar ratio 3:1, the mass accounts for 30% of the total mass of the catalyst), weigh the carbon powder slurry equivalent to 0.4g carbon powder after ultrasonic and stress shearing treatment, follow the above steps Add 0.8g NaHCO 3 Adjust the pH to 8.5, slowly drop 6.8944ml of 0.1158mol / L chloroplatinic acid solution, 2.2522ml of the same concentration of nickel nitrate solution and the prepared 1.5g of ethylene glycol solution into the slurry successively under magnetic stirring, and mix evenly Stir and control the reaction temperature to react at 85°C. After filtering and cleaning, at 600°C, a mixed gas of hydrogen and argon (H 2 :Ar=1:4) heat treatment for 2h to get 30%Pt 3 Ni / C catalyst. Get catalyst and carry out XRD test ( image 3 ) and electrochemical characterization (Table 1), image 3 It can be seen that the crystallization degree of the catalyst Pt particles is good, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com