Two-level breaking recovery device for corrugated cases

A recycling device and corrugated box technology, applied in the direction of grain processing, etc., can solve the problem of low crushing efficiency, achieve the effect of improving the crushing effect and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

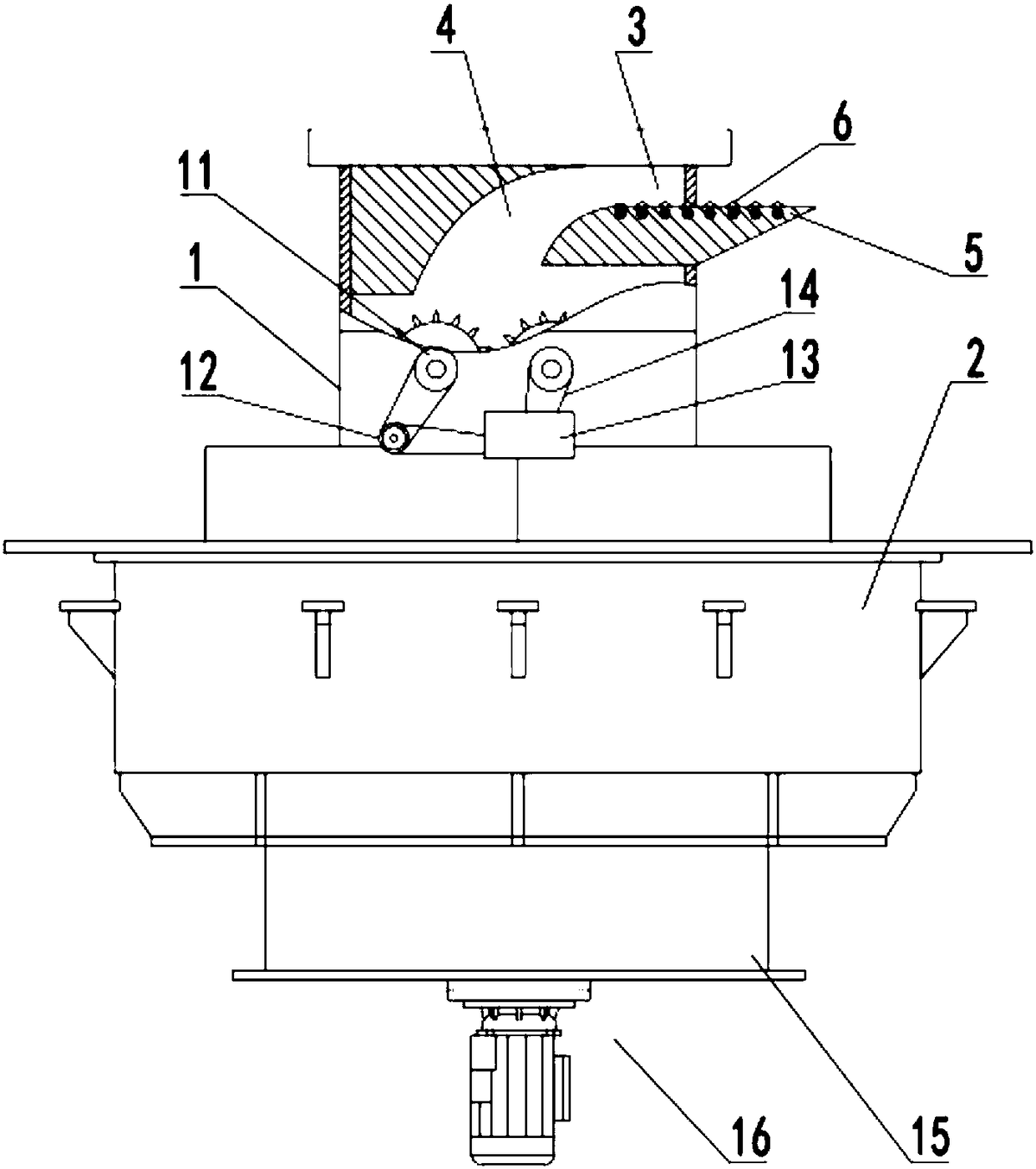

[0022] see Figure 1~2 , in an embodiment of the present invention, a two-stage crushing and recycling device for corrugated cardboard boxes, including a shell with an inner cavity formed by fixedly splicing the upper shell 1 and the lower shell 2, and the cavity in the shell is from top to bottom The first and second crushing mechanisms are installed on the bottom, that is, the corrugated box or corrugated cardboard is crushed twice by the first crushing mechanism and the second crushing mechanism, specifically;

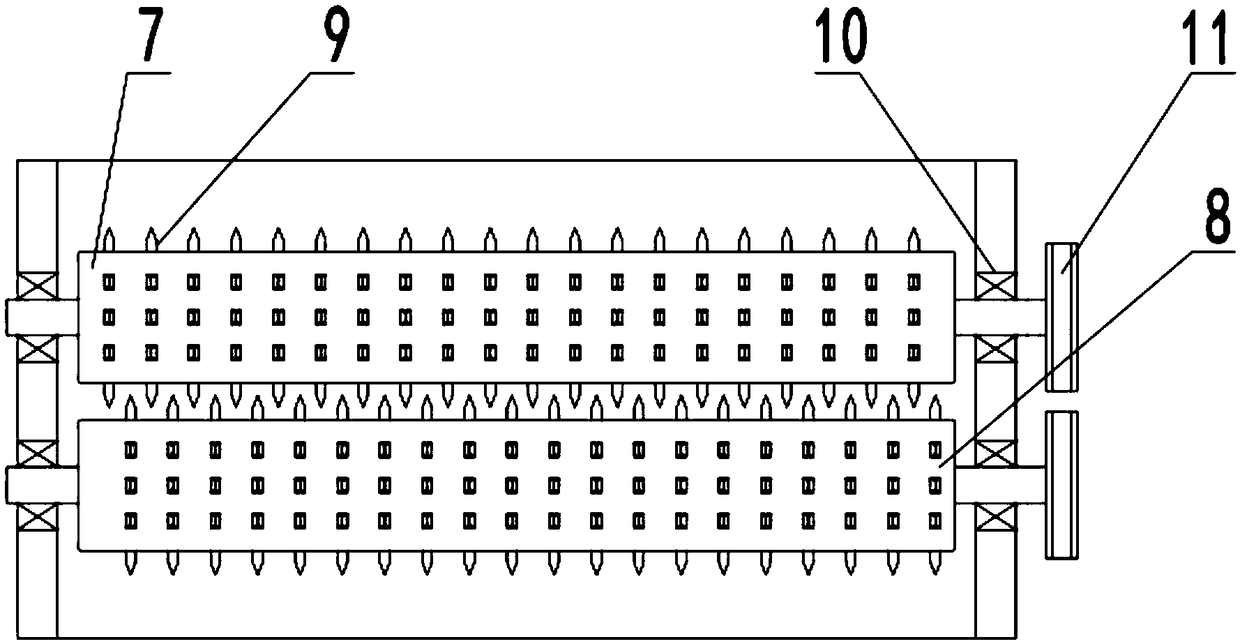

[0023] The first crushing mechanism includes a first crushing roller 7 and a second crushing roller 8 installed in the housing through a bearing 10, and a plurality of crushing knives 9 are fixed on the surfaces of the first crushing roller 7 and the second crushing roller 8, and the first crushing roller 7 and the second crushing roller 8 The position of the crushing knife 9 on the crushing roller 2 8 is staggered, the rotation direction of the crushing roller 1 7 ...

Embodiment 2

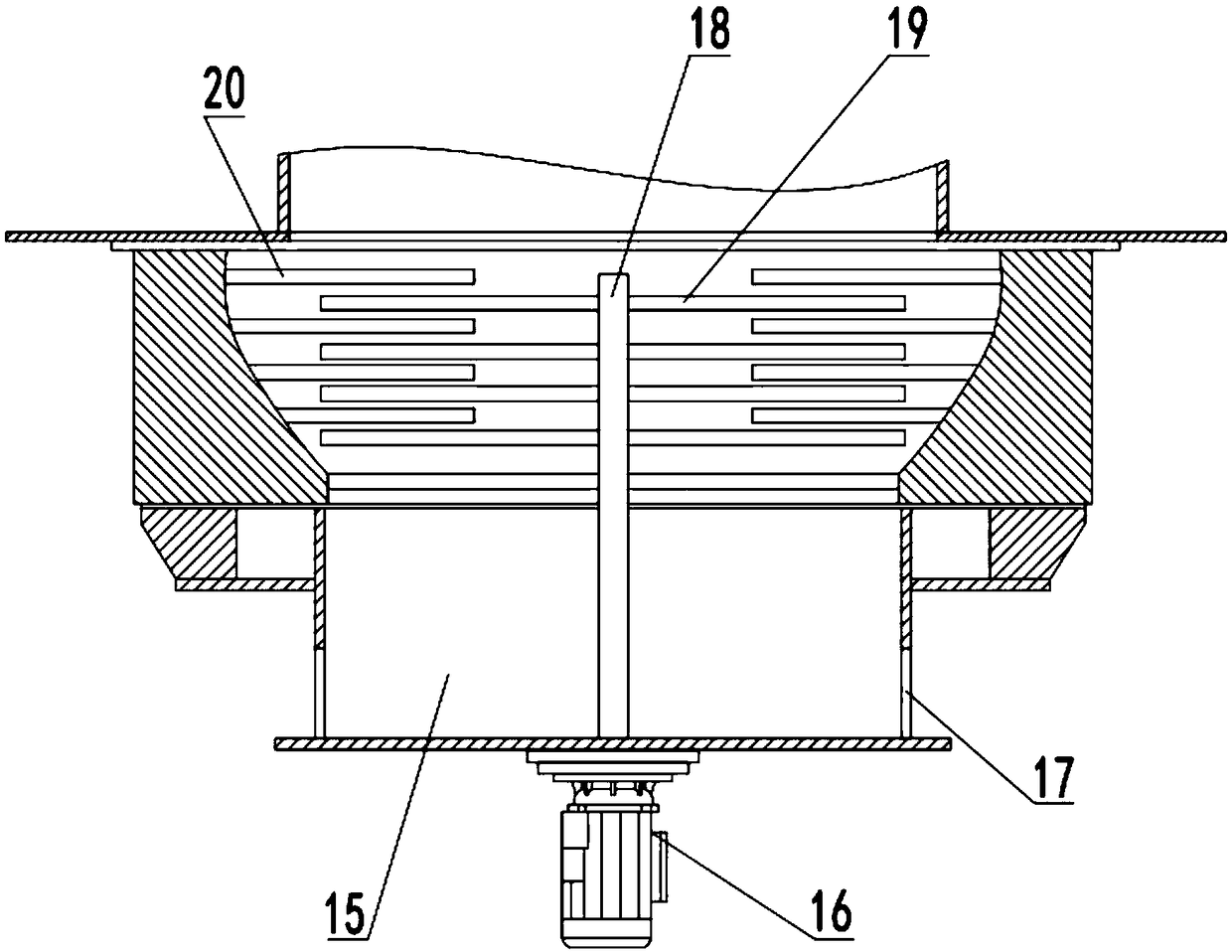

[0028] see image 3 , on the basis of embodiment 1, this embodiment further describes the structure of the crushing mechanism two, specifically,

[0029] The crushing mechanism two includes a crushing motor two 16, a rotating shaft 18 and a crushing blade one 19, the crushing motor two 16 is installed on the bottom of the material storage box 15, the output end of the crushing motor two 16 and the rotating shaft 18 extending into the housing cavity connection, the crushing motor 16 is electrically connected with the external power supply and the control switch, and a plurality of crushing blades 19 are fixed on the outside of the rotating shaft 18. When the crushing motor 2 16 outputs power, the crushing blades 19 rotate at a high speed, and the crushing blades 19 will pass through the crushing process. The corrugated cardboard box or corrugated cardboard crushed by roller one 7 and crushing roller two 8 is crushed again, and the corrugated cardboard box or corrugated cardboar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com