Press riveter with special-shaped head stripping plate

A technology of specific shape and stripping plate, which is applied in the direction of threaded fasteners, connecting components, nuts, etc., can solve the problems of parts interference, etc., and achieve the effect of fast and effective maintenance without affecting safety, reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

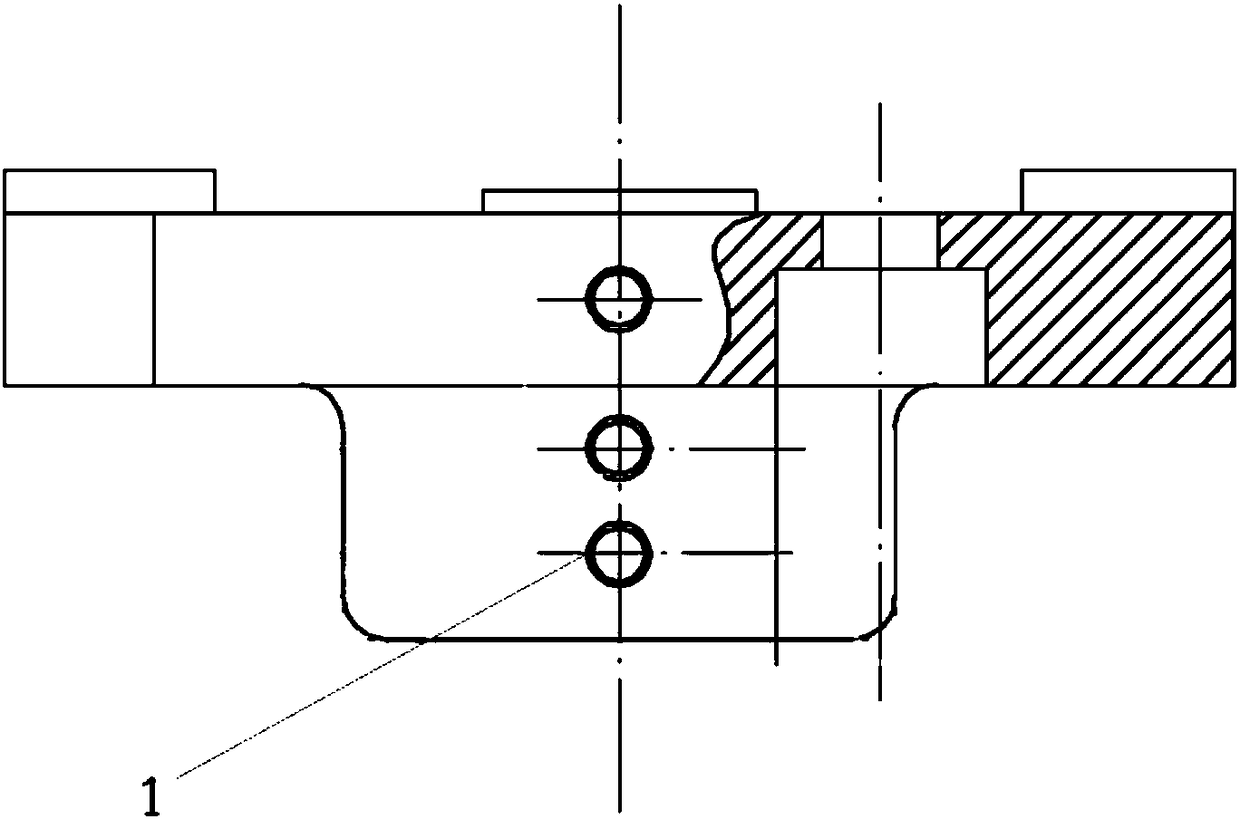

[0022] Based on the existing riveting device, the present invention mainly changes the outer circular shape of the head of the stripping plate, so that the head of the stripping plate has a convenient solution in the case of parts interference, and can promptly eliminate product quality problems generated during the production process. And the changed shape of the outer circle of the head of the release plate does not affect its function. The invention solves the method of quickly finding the cause of the failure.

[0023] Specific structure:

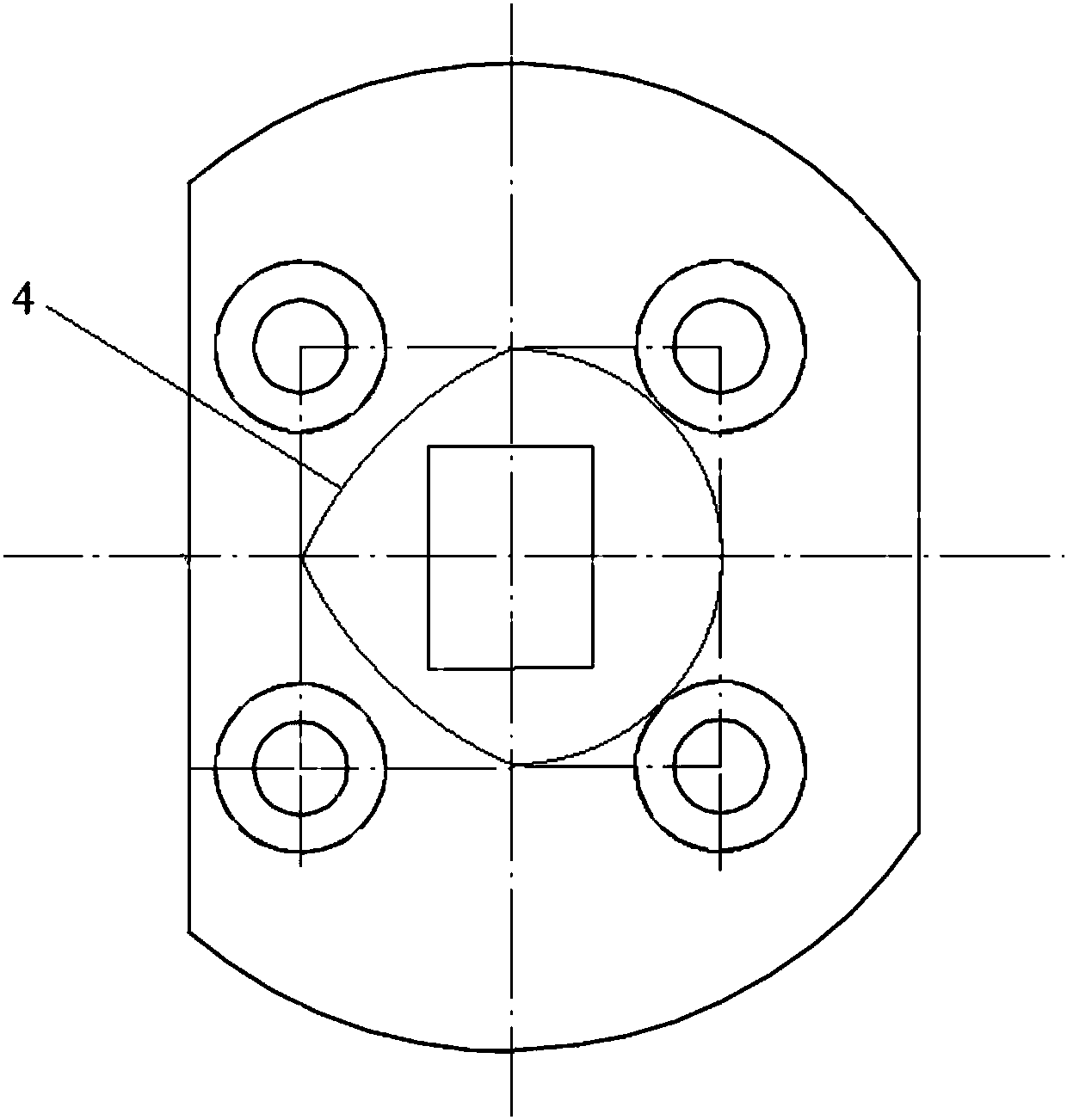

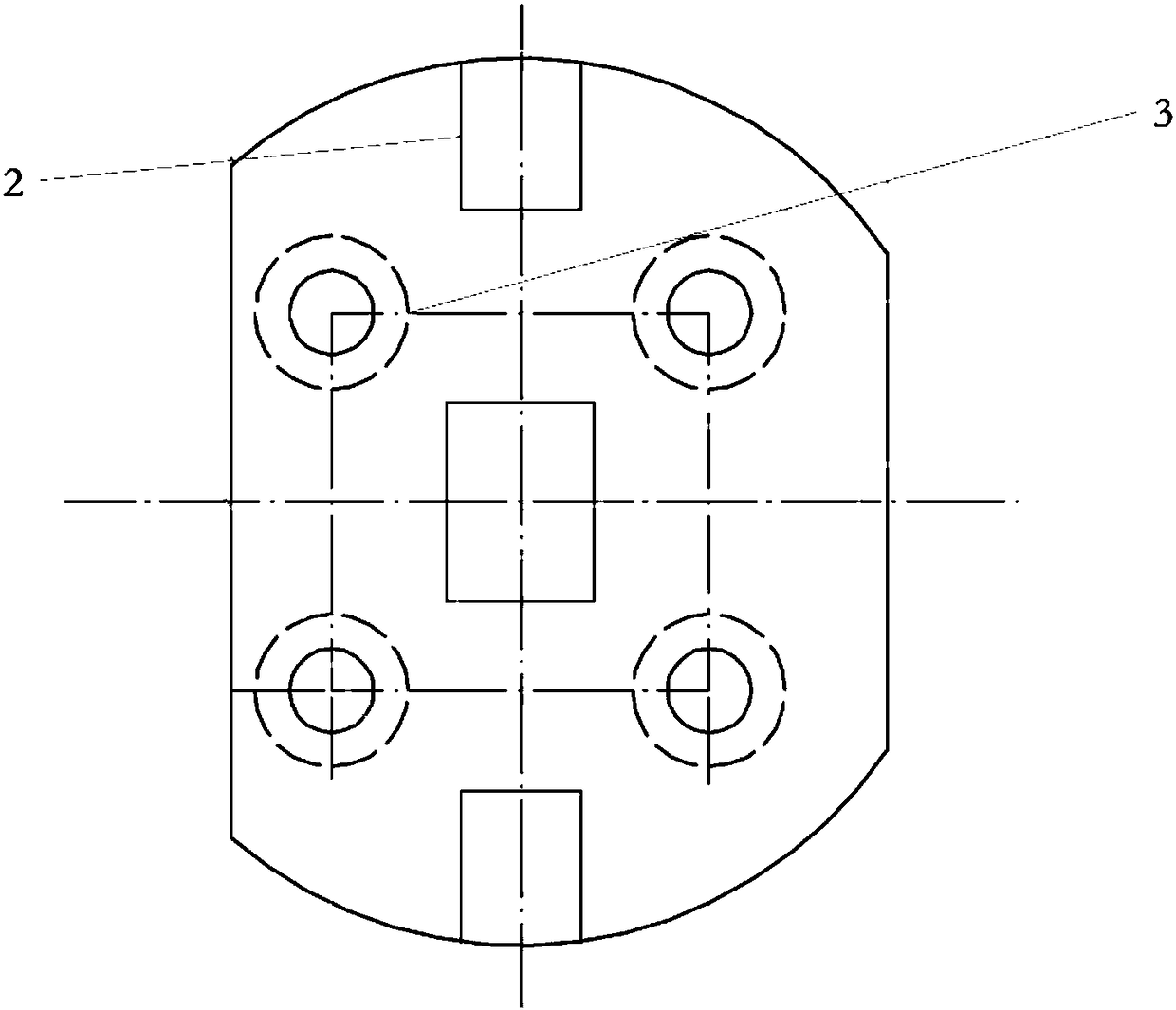

[0024] A riveter with a stripping plate of a specific shape head. The rivet includes a stripping plate, a guide post and a stamping unit connected in sequence. A protrusion 4 is provided in the middle of the side of the stripping plate that contacts the stripping part, such as figure 1 As shown, the raised shape is half arc-shaped, half of which is formed by two symmetrical arcs. If the radius of the arc-shaped half of the raised arc i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com