Core head structure not prone to being mixed with residual sand and stable in position

A technology of core head and residual sand, which is applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problems of mixing residual sand, affecting the stability of runner cores, and large differences in wall thickness of volute castings. The effect of floating and positioning stability

Inactive Publication Date: 2019-01-04

KEHUA HLDG

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] During the production process of Ningbo Fengwo Company’s turbocharger volute production task undertaken by our company, due to the large difference in wall thickness of the volute castings, in order to make the cooling speed of the castings close to each other, chillers are installed on parts such as the intake flange. , but the orifice of the inlet flange is also the position where the core of the runner is positioned. Since the aperture of the cold iron and the core cannot be closely matched, there are many and large gaps. During molding, residual sand is mixed in the gap between the apertures of the cold iron, and at the same time It also makes the core head easy to float, which affects the stability of the runner core in the cavity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

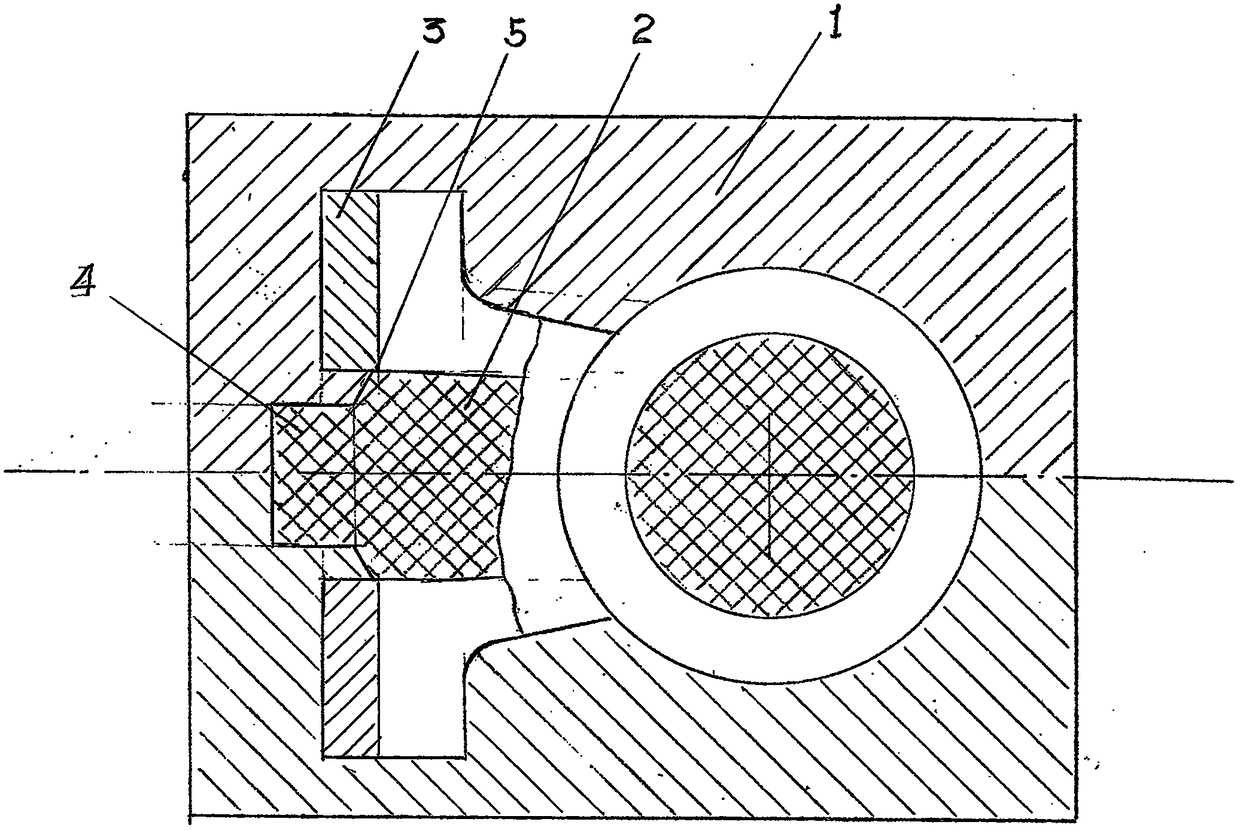

[0008] The outer diameter of the core head 4 of the runner core 2 is smaller than the hole diameter of the cold iron 3, and only a small part of the positioning head 5 with a larger diameter is left at the rear end for pre-positioning when the core is lowered. During molding, the sand of the shell type 1 enters the hole of the cold iron 3 Closely cooperate with the core head 4 to complete the final positioning.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a core head structure not prone to being mixed with residual sand and stable in position. In the modeling of a turbocharger volute, a volute channel core needs to be used, a core head is positioned at an opening of a gas inlet flange, since the wall thickness difference is large, the temperature is balanced by the gas inlet flange and other cold iron, the core head is arranged in a cold iron hole, and not only a gap exists, but also there is a floating phenomenon. Nowadays, the core head feeding is decreased, a gap which is about 5 mm wide is generated between the corehead and the cold iron hole, modeling sand enters the gap during modeling for curing and positioning, no seams exist, and the positioning floating phenomenon is eliminated.

Description

technical field [0001] The core head structure of the foundry industry sand core positioned in the shell mold. Background technique [0002] During the production process of Ningbo Fengwo Company’s turbocharger volute production task undertaken by our company, due to the large difference in wall thickness of the volute castings, in order to make the cooling speed of the castings close to each other, chillers are installed on parts such as the intake flange. , but the orifice of the inlet flange is also the position where the core of the runner is positioned. Since the aperture of the cold iron and the core cannot be closely matched, there are many and large gaps. During molding, residual sand is mixed in the gap between the apertures of the cold iron, and at the same time It also makes the core head easy to float, which affects the stability of the runner core in the cavity. Contents of the invention [0003] The present invention is a core head structure that is not easi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22C9/02B22C9/24B22C9/10

CPCB22C9/02B22C9/10B22C9/24

Inventor 曹先进

Owner KEHUA HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com