Rapid deicing method for high-speed train bogie with hot micro-sand spraying method

A technology for high-speed trains and bogies, applied in railway auxiliary equipment and other directions, can solve the problems of destroying bogie parts, hindering the normal movement of each part of the bogie, reducing maintenance reliability, etc. Increase the effect of freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

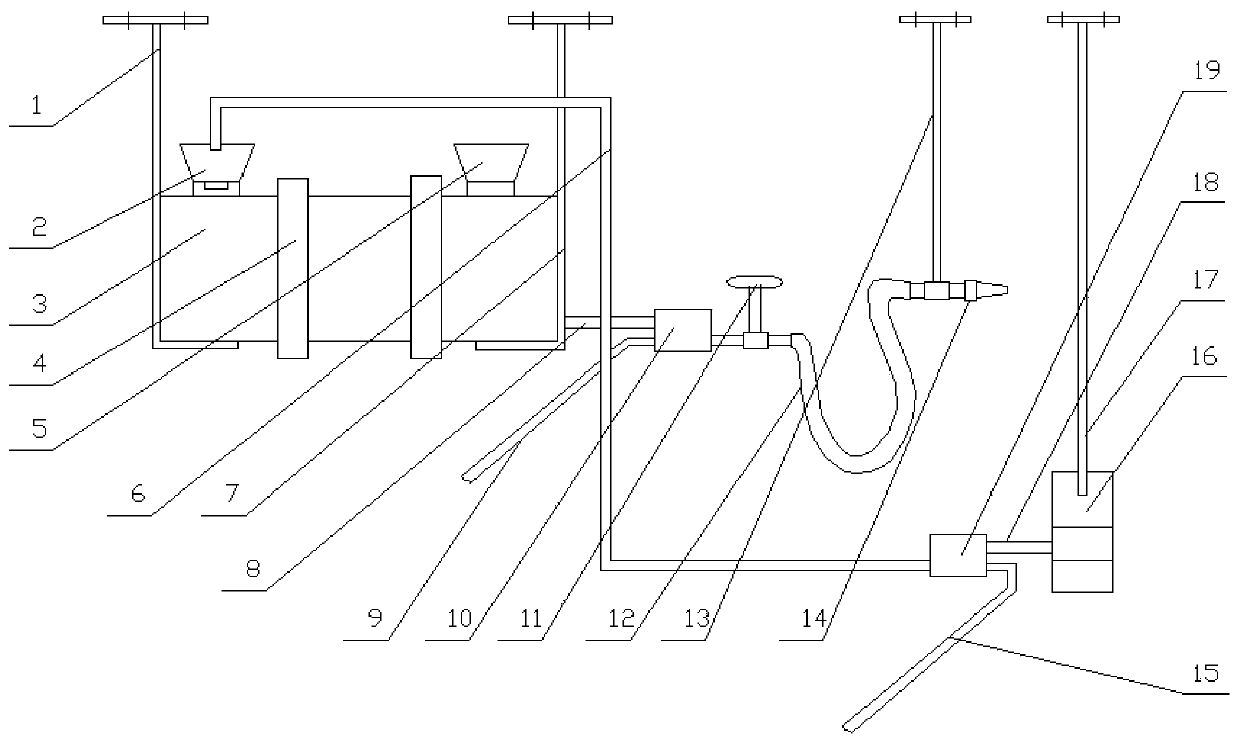

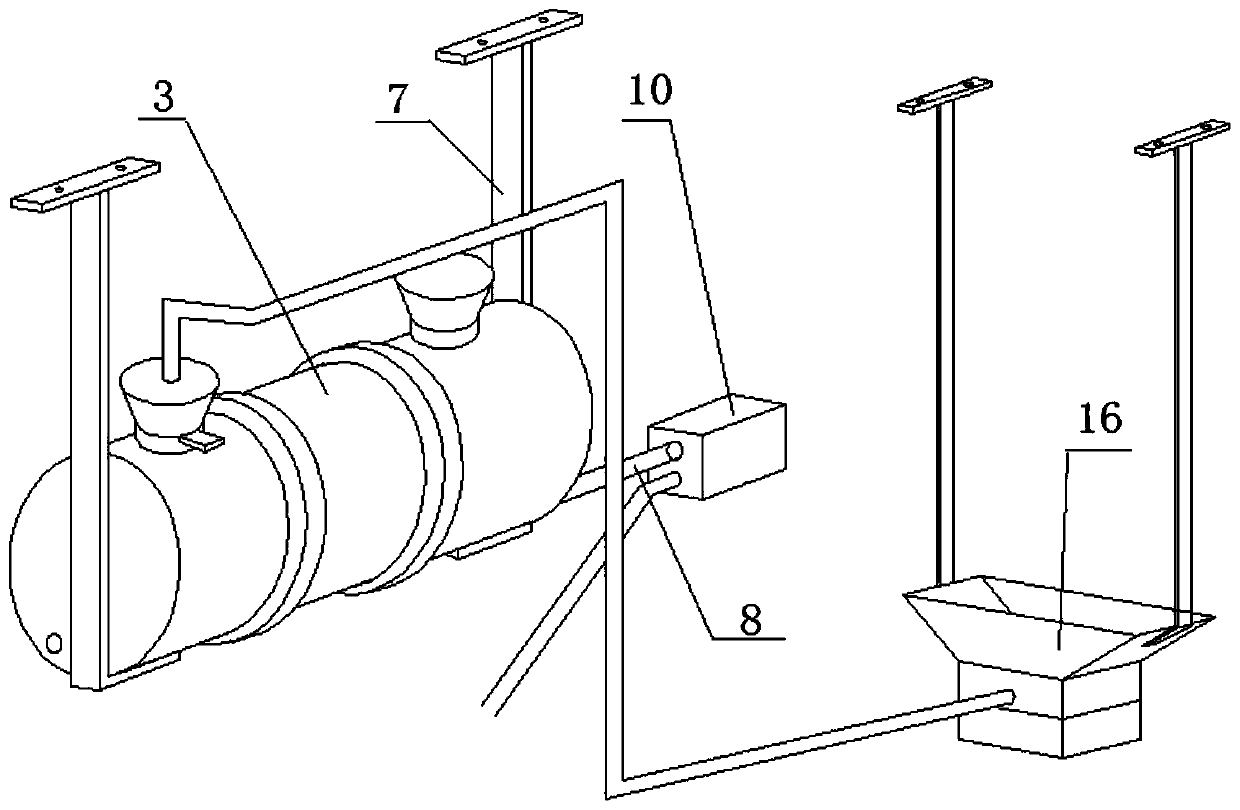

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The purpose of the present invention is to use the tiny hot sand grains with heat to spray into the ice layer on the train bogie, immediately the ice will be made into a honeycomb shape, and the heat of the hot sand will directly melt the ice layer.

[0022] For the compartment of a high-speed rail train, the car body is located at the upper part, and the bogie, as the running part, is located at the lower part. Considering that there is sufficient installation space under the car, the devices in this system are hung under the car body through the hanging rod, which is also It can be hung and fixed on the proper part of the bogie.

[0023] Such as figure 1 As shown, the sand storage box 3 is used to store tiny sand grains. It is suspended by the left sand storage box suspension rod 1 and the right sand storage box susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com