Anti-rollover body mechanism of multi-wheel truck

An anti-rollover and wheel-loading technology, applied in passenger bicycles, bicycles, motor vehicles, etc., can solve the problems of easy rollover, potential safety hazards, and easy tilting of the body, so as to reduce the impact of centrifugal force and avoid rollover. , to ensure the effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

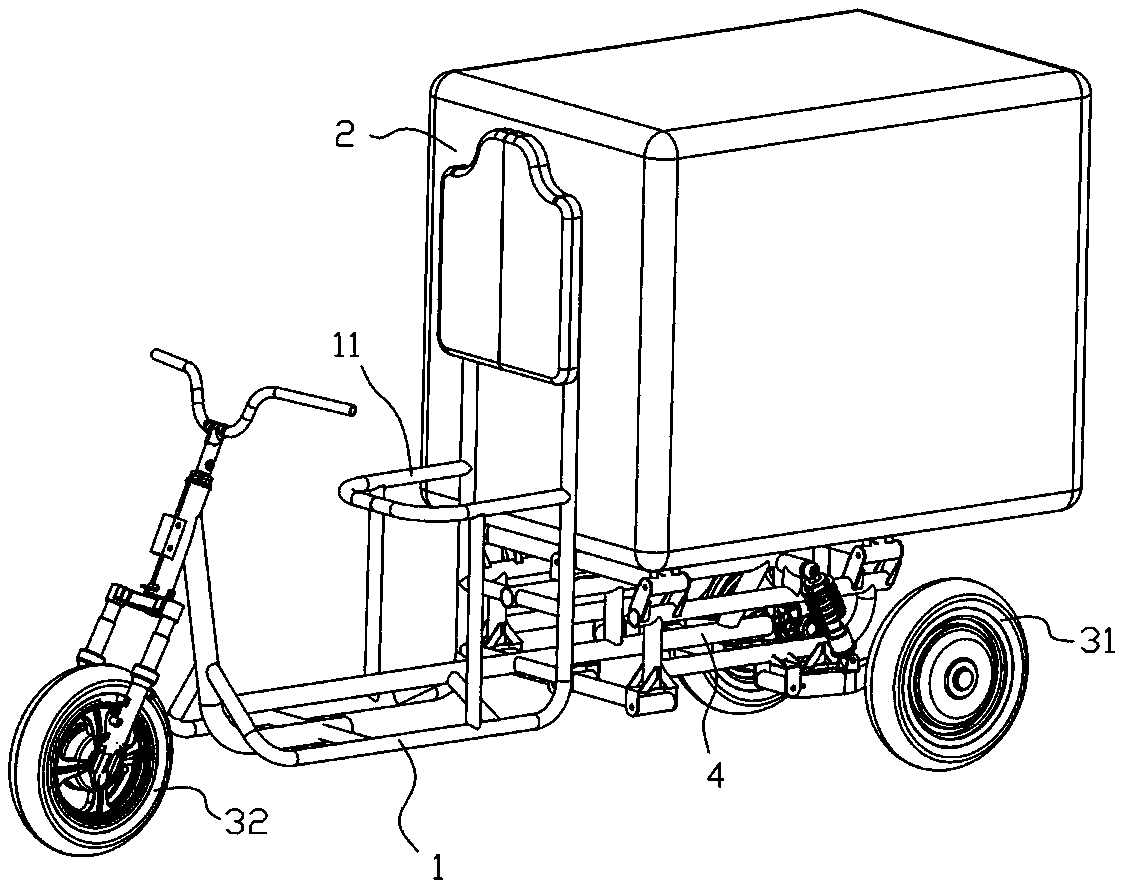

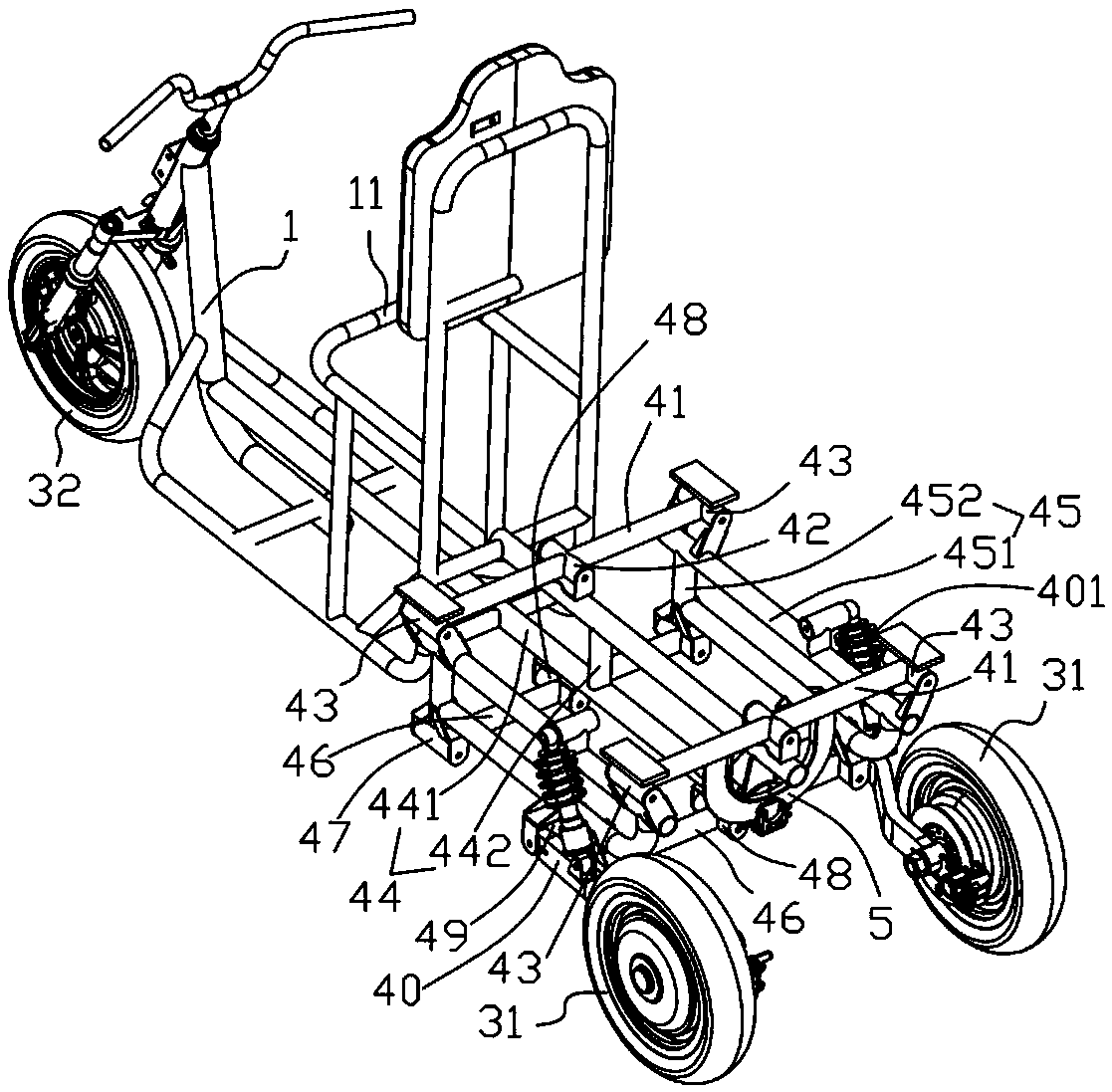

[0019] like Figure 1-4 As shown, an anti-rollover body mechanism of a multi-wheeled cargo vehicle includes a vehicle frame 1, on which a cargo box 2 is arranged, and at least three wheels are arranged under the vehicle frame 1. In the illustration of this embodiment, only the structure of three wheels is described, but in practice it can be set to four or more wheels as required.

[0020] Two of the wheels constitute two linkage adjusting wheels 31 , and the other wheels 32 are located at the front side or the rear side of the adjusting wheels 31 . The two adjustment wheels 31 are arranged in parallel and at intervals on both sides below the load box 2 , and the two adjustment wheels 31 are connected with the vehicle frame 1 and the load box 2 through a linkage adjustment mechanism 4 .

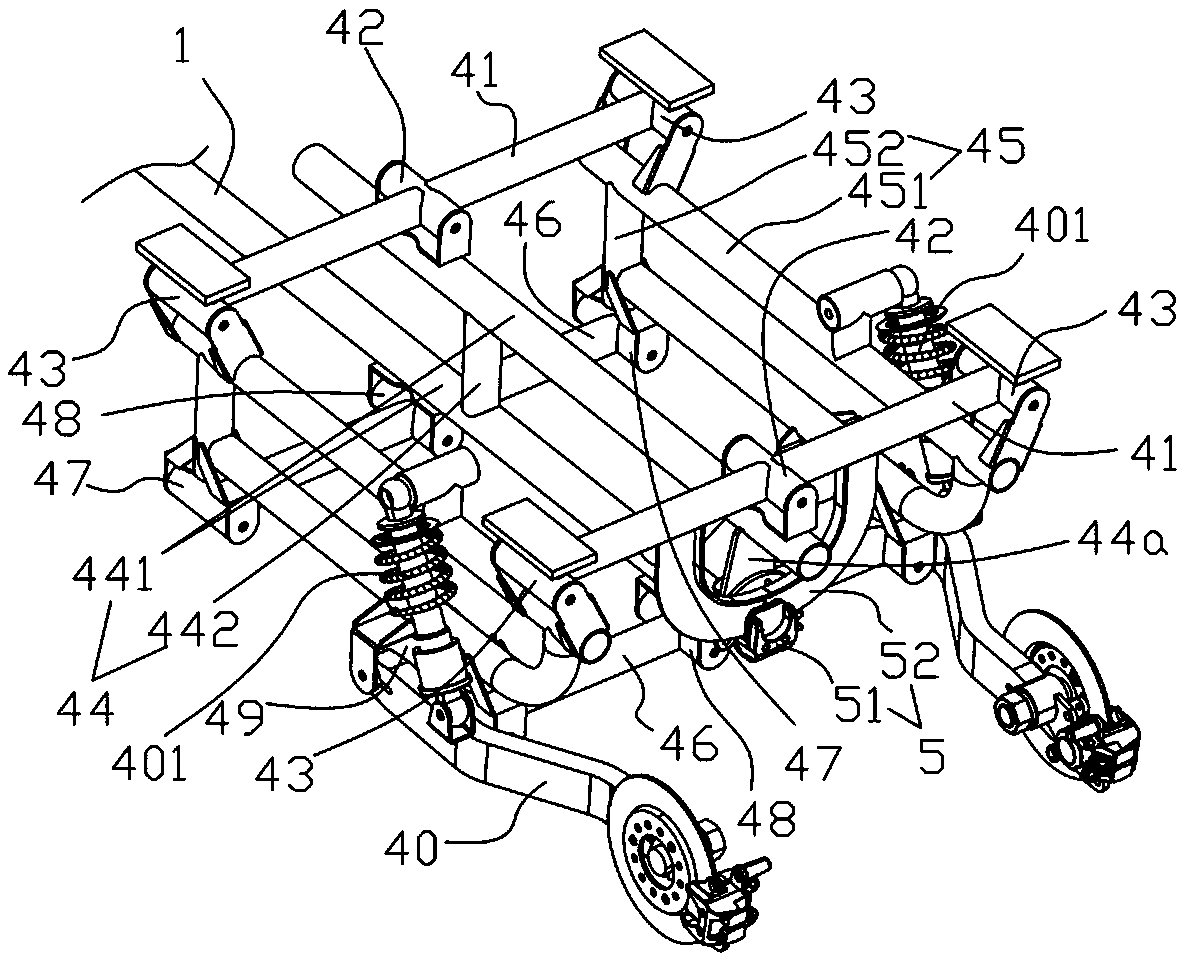

[0021] The linkage adjustment mechanism 4 includes at least two upper rails 41 positioned below the cargo box 2. In this illustration, two upper rails 41 are used. In practice, more upper ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com