A multi-lobe concentrating soot swirl mixing partition and exhaust after-treatment device

A swirl mixing and soot technology, which is applied to exhaust treatment, exhaust devices, mufflers, etc., can solve the problems of unsatisfactory mixing effect of airflow and soot, uneven distribution of soot particles, large temperature gradient, etc. Achieve the effect of improving uniformity, reducing the uniformity of temperature distribution, and reducing the influence of centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

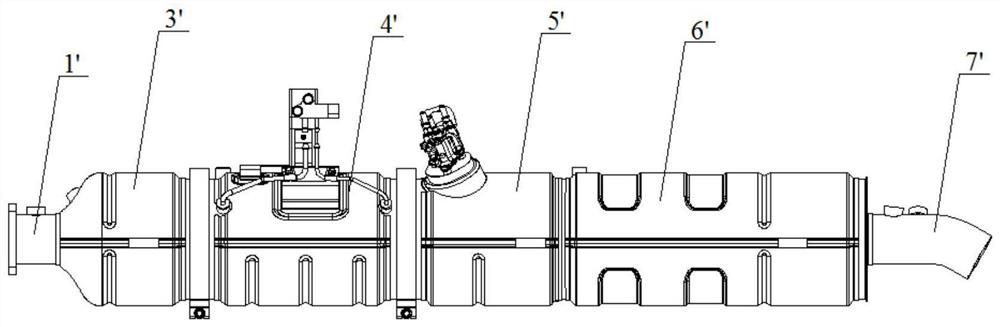

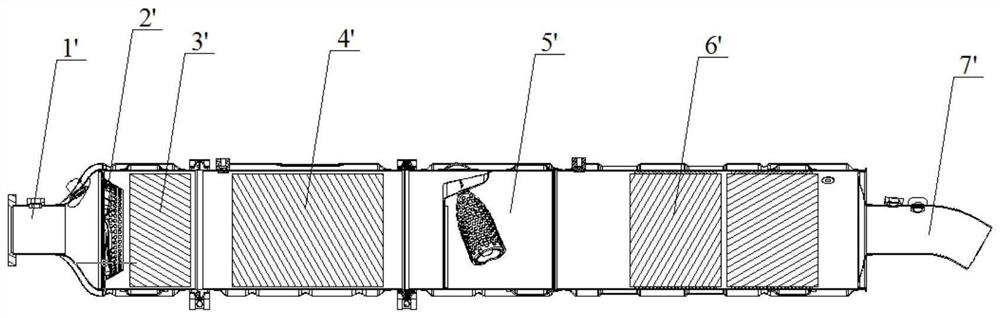

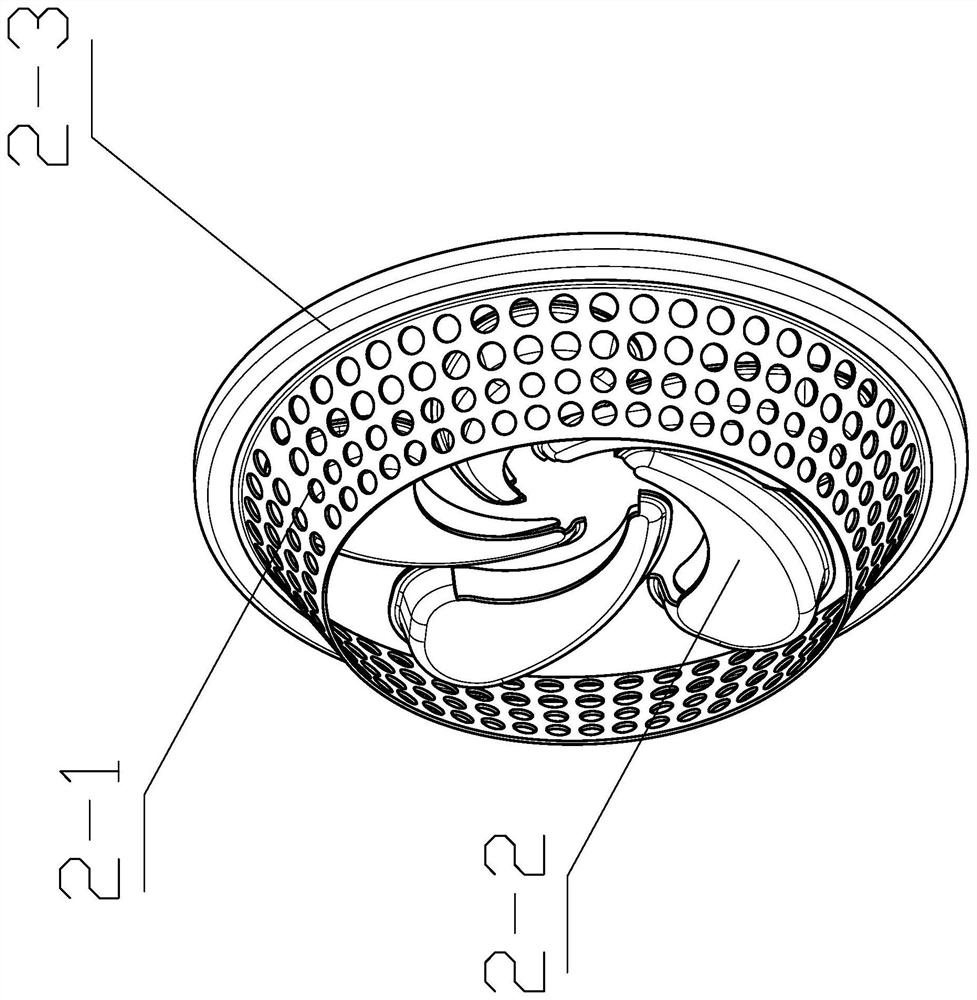

[0025] Figure 1-6 , including intake pipe assembly 1, multi-lobe converging soot swirl mixing plate 2, conical orifice plate 2-1, orifice plate connection end 2-11, orifice plate middle exhaust end 2-12, soot side Exit 2-13, swirl blade 2-2, swirl cladding plate 2-21, swirl top plate 2-22, soot swirl outlet 2-23, support plate 2-3, soot inlet 2-31, DOC Component 3, DPF component 4, urea mixer component 5, SCR component 6, exhaust tailpipe component 7, etc.

[0026] Such as Figures 1 to 2 As shown, the present invention is a kind of exhaust post-processing device, and the exhaust post-processing device consists of an intake pipe assembly 1, a multi-lobe concentrating soot swirl mixing plate 2, a DOC assembly 3, a DPF assembly 4, and a urea mixing The device assembly 5, the SCR assembly 6 and the exhaust tailpipe assembly 7 and other comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com