A preparation system and process of tungsten carbide powder

A technology of tungsten carbide powder and preparation system, applied in carbides, tungsten/molybdenum carbides, chemical instruments and methods, etc., can solve the problem that the quality of tungsten carbide is difficult to further improve, the calcination effect of tungsten carbide is not good, and the grinding ball is difficult to contact To avoid the accumulation of material powder, enhance the grinding effect, and improve the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

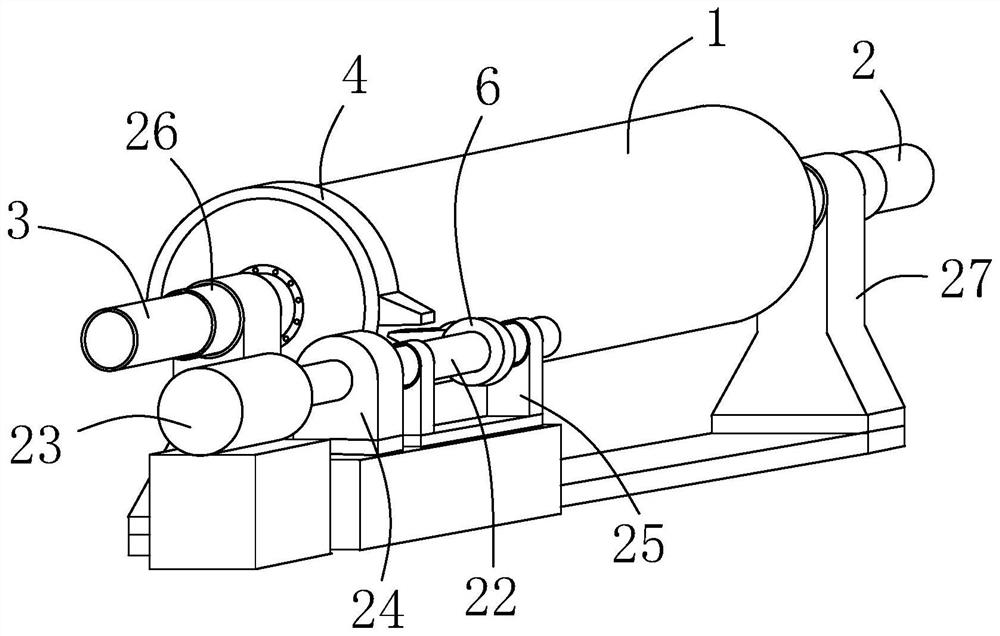

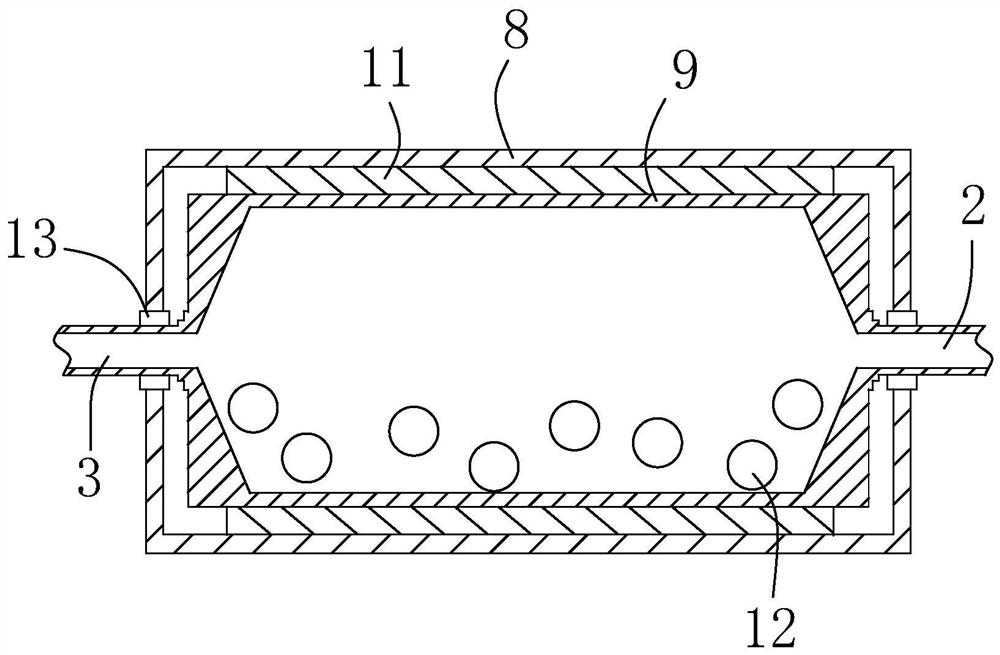

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

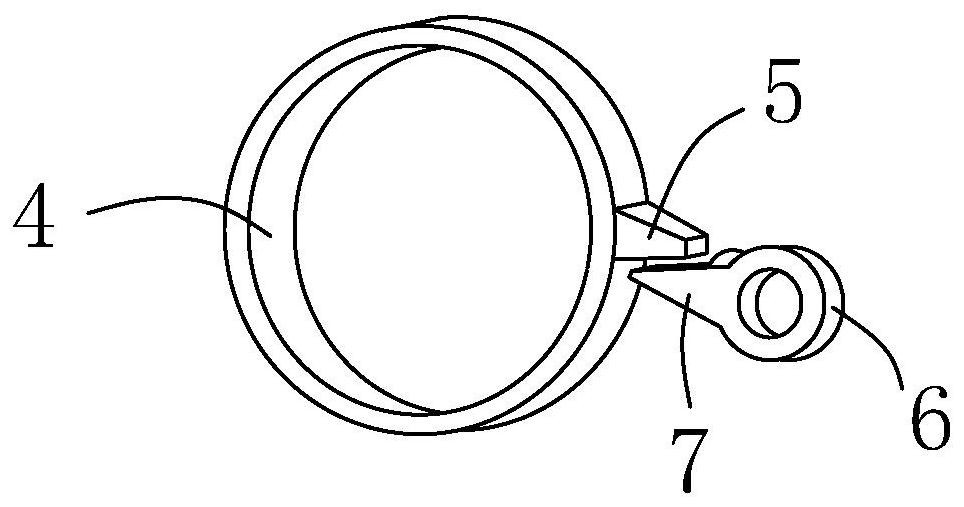

[0033] The feed pipe and the discharge pipe are all equipped with a rotary joint. As shown in FIG. 5 , the rotary joint includes a fixed shell 14 and a rotary

[0035] A rotary seal 21 is provided between the bottom of the rotary cup and the fixed shell.

[0038] The feed side of the grinding cylinder is higher than the discharge side, which facilitates the use of gravity to discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com