mql oil mist terminal mixing system

A mixing system and oil mist technology, applied in the direction of mixers, mixing methods, manufacturing tools, etc., can solve the problems of oil mist reduction, large oil mist particles, control lag, etc., and achieve simple structure, small volume, and solve control lag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

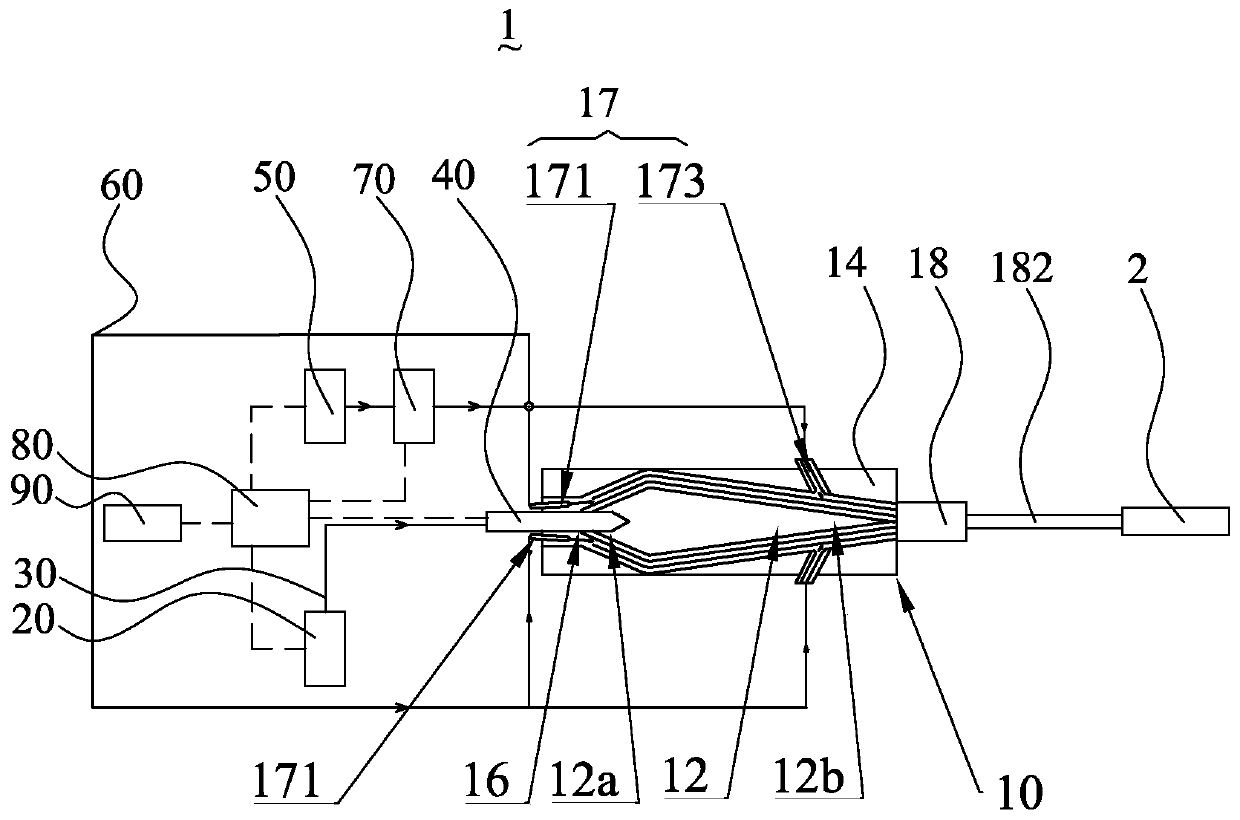

[0016] Such as figure 1 As shown, the MQL oil mist terminal mixing system 1 of the present invention includes an oil-gas mixing chamber 10, an oil booster 20, at least one first delivery pipe 30, at least one first control valve 40, an air booster 50, and at least one second The delivery pipe 60 , at least one second control valve 70 and the PLC control system 80 .

[0017] Specifically, the oil-gas mixing chamber 10 is generally made of metal and has an inner chamber 12 and a chamber wall 14. The inner chamber 12 is shuttle-shaped and has a front end 12a and a rear end 12b. The rear end 12b is narrower than the front end 12a. The wall 14 defines at least one first inlet 16 , at least one second inlet 17 and at least one outlet 18 . In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com