Hull cleaning mechanism of wall climbing robot

A technology of a wall-climbing robot and a cleaning mechanism, which is applied to ship hulls, ship cleaning devices, motor vehicles, etc., can solve the problems of complex structure, centralized processing, inconvenient use, etc., and achieves convenient dust collection, increased workload, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

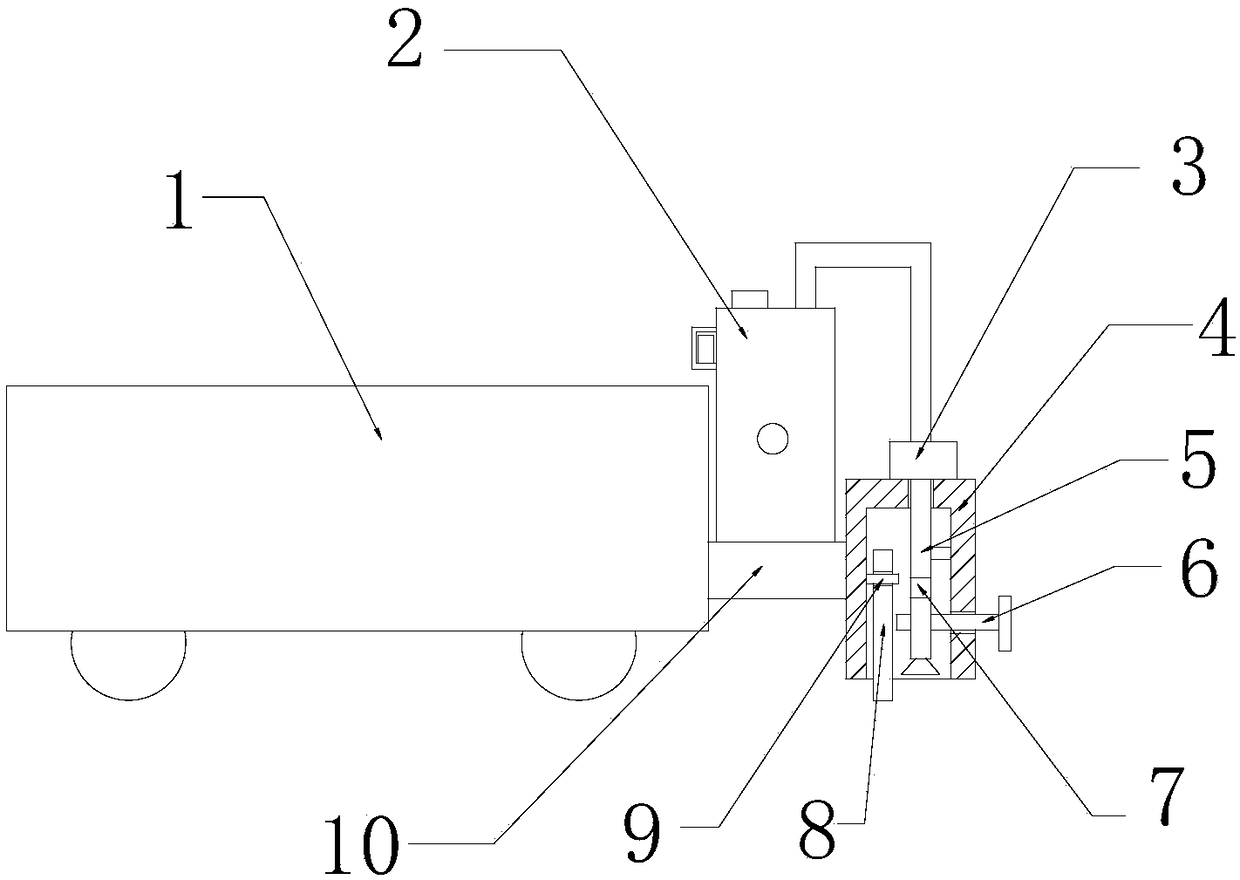

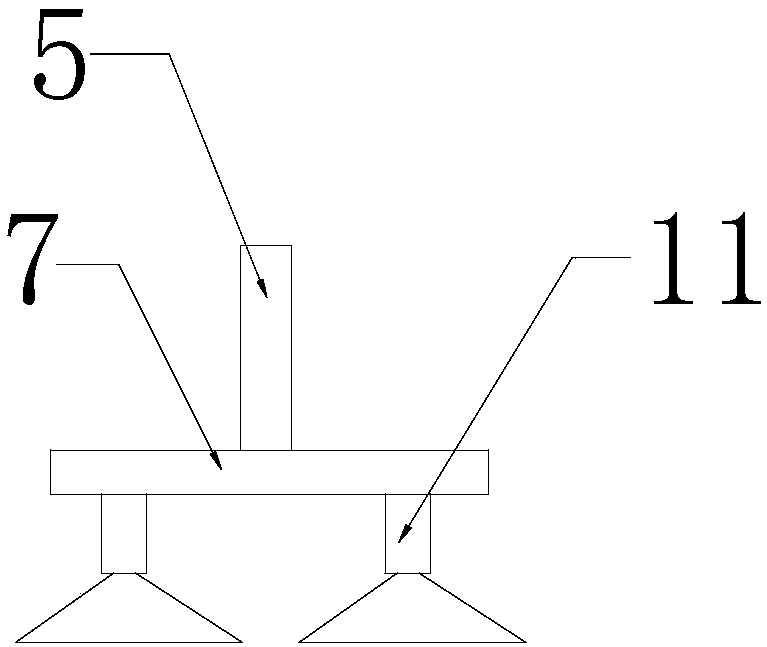

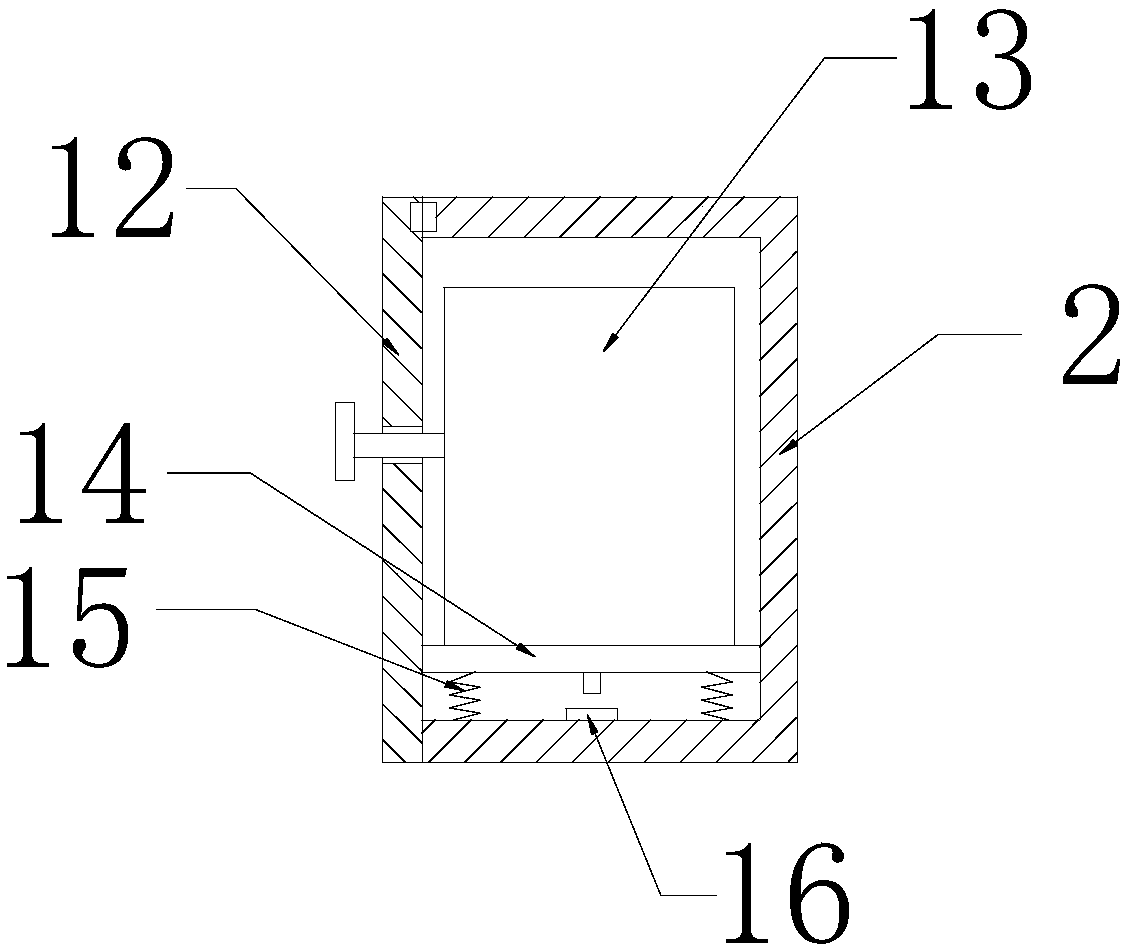

[0018] Specific implementation method: when cleaning is required, the operator runs the wall-climbing robot body 1 to move to the right, the wall-climbing robot body 1 drives the installation plate 10 to move to the right, the installation plate 10 drives the box body 2 to move to the right, and at the same time drives the U-shaped plate 4 Move to the right, the box body 2 drives the front cover 12, the collection box 13, the pressure plate 14, the spring 15 and the contact switch 16 to move to the right, and the U-shaped plate 4 drives the suction fan 3, the conduit 5, the bolt 6, the horizontal pipe 7, and the scraper 8. The positioning rod 9 and the suction head 11 move to the right, the scraper 8 cleans the dust and debris on the surface of the hull, and at the same time, the suction fan 3 is operated, and the suction fan 3 generates suction, and the dust is sucked into the conduit 5 through the suction head 11, and Enter the collection box 13 through the connecting pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com