Screw-type vertical elevator and working method thereof

一种工作方法、螺杆式的技术,应用在建筑物内的电梯、升降机、运输和包装等方向,能够解决轿厢坠落风险、乘客踩空等问题,达到保证可控性和安全性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

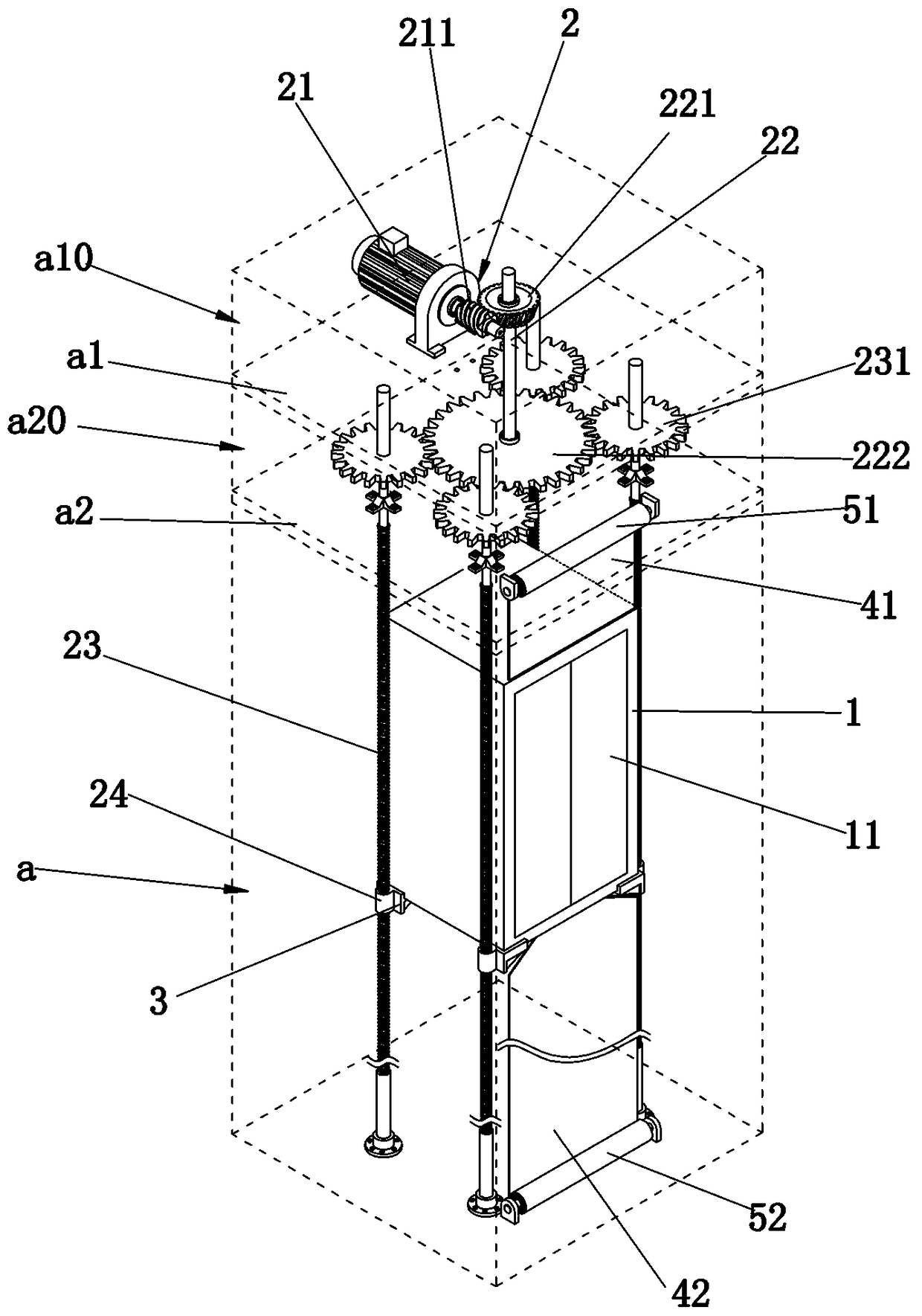

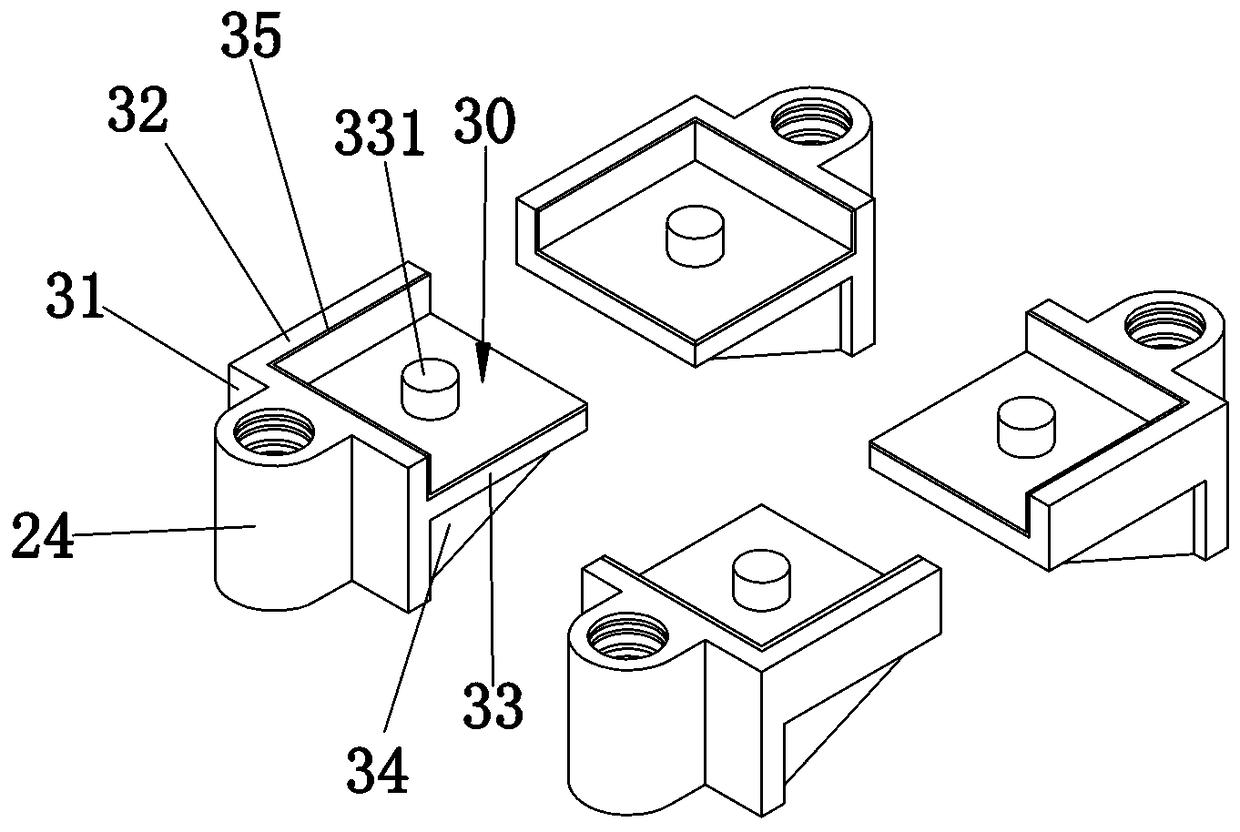

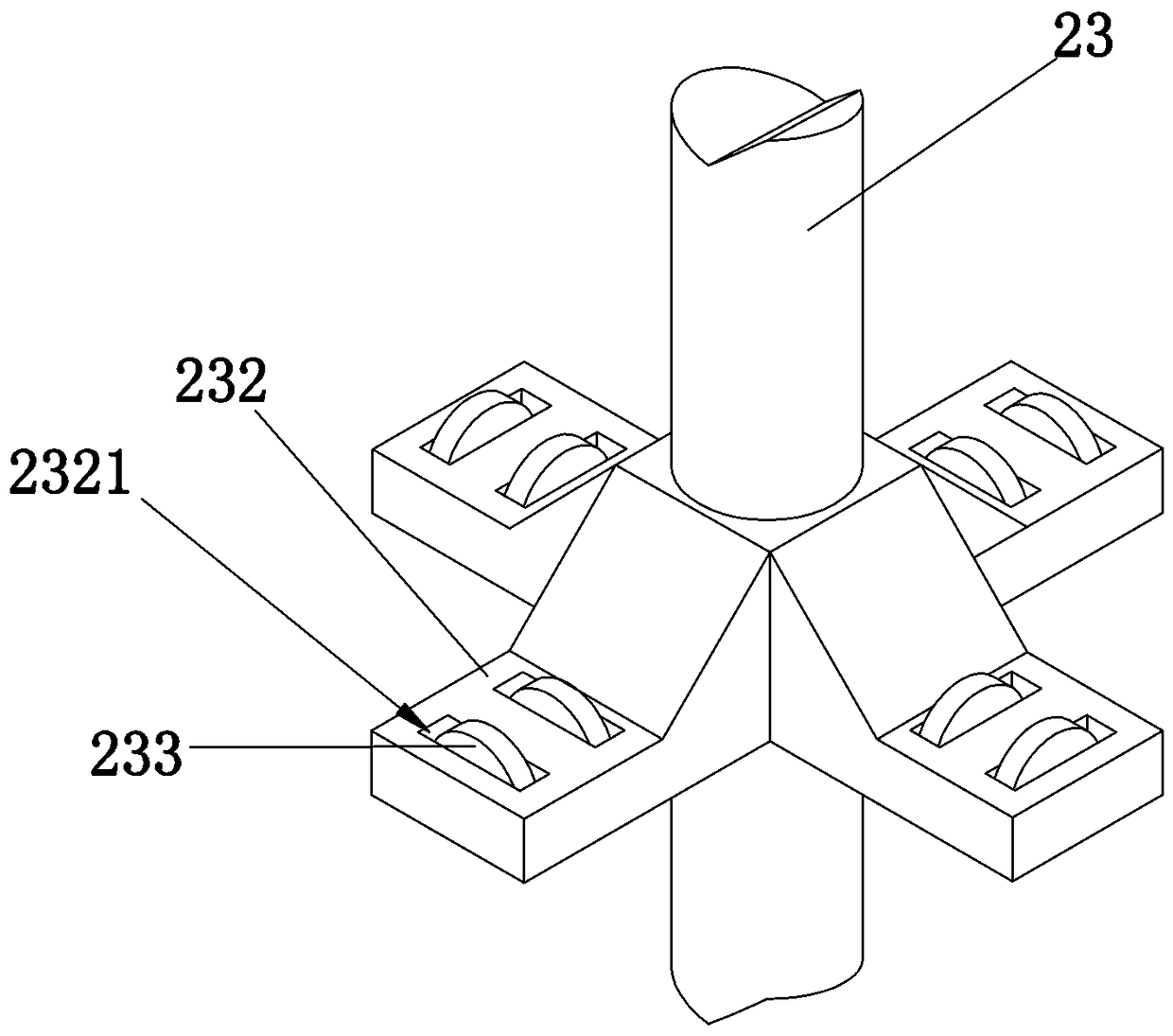

[0030] refer to figure 1 , a screw-type vertical elevator, including a shaft a, a car 1 and a driving mechanism 2 for vertically lifting the car 1 in the shaft a. The driving mechanism 2 includes a motor 21 , a transmission rod 22 and a plurality of screws 23 . Wherein a plurality of screw rods 23 are vertically arranged around the car 1, and the upper and lower ends of each screw rod 23 are rotatably arranged at the upper and lower ends of the hoistway a. Each screw rod 23 is sleeved with a nut 24 , and the nut 24 is connected to the car 1 through the first connecting piece 3 . Each screw 23 is provided with a second gear 231, the output shaft of the motor 21 is provided with a worm 211, the upper end of the transmission rod 22 is provided with a worm wheel 221 meshed with the worm 211, and the lower end is provided with the second gear 231 of each scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com