Self-lubricating hinge

A self-lubricating and hinge technology, which is applied to hinges, hinges with pins, construction, etc., can solve problems such as short lubrication duration, slow hinge speed of lubricating oil, harsh friction sound, etc., and achieve simple and easy disassembly line, improve utilization, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

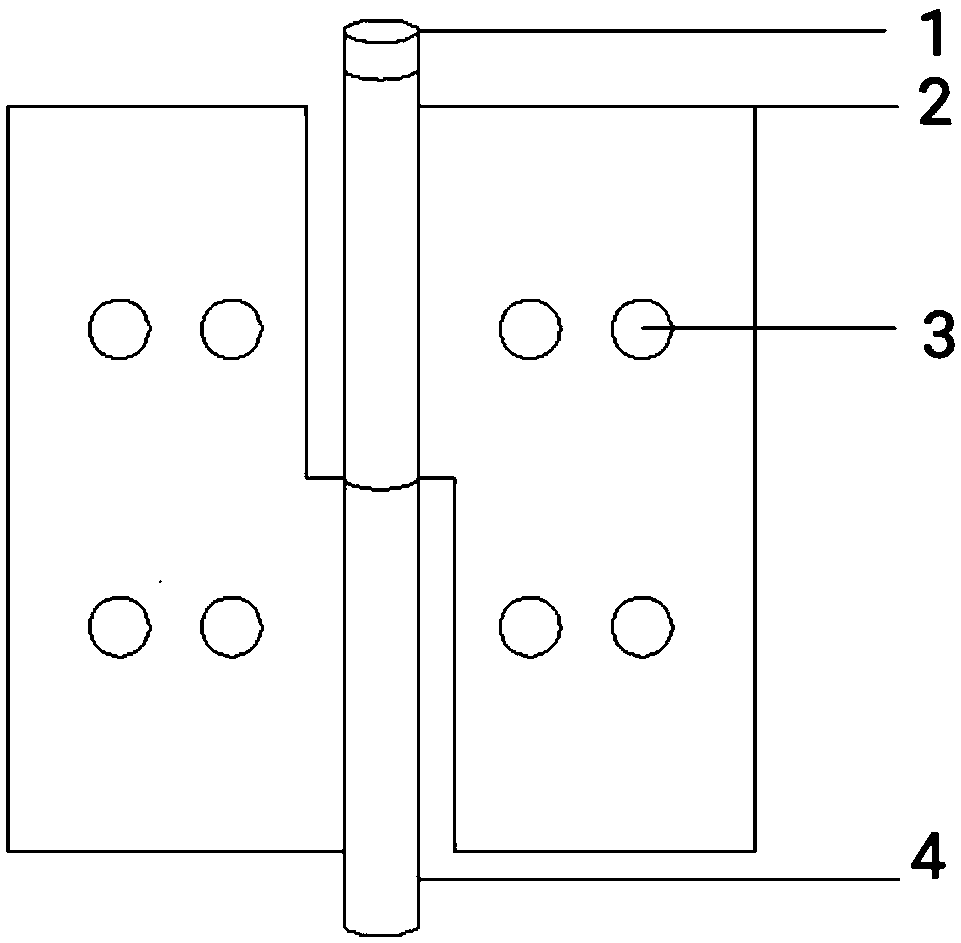

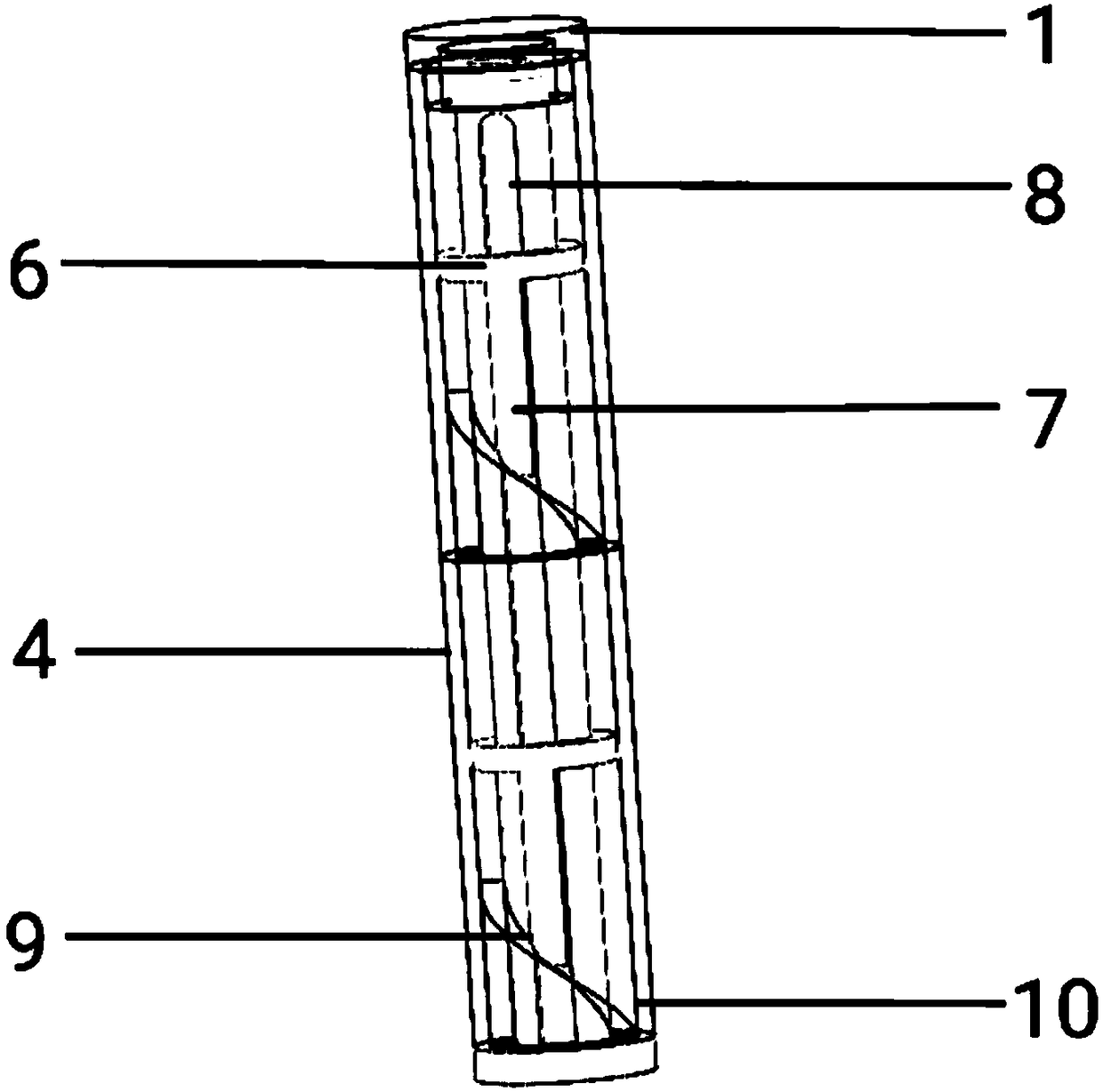

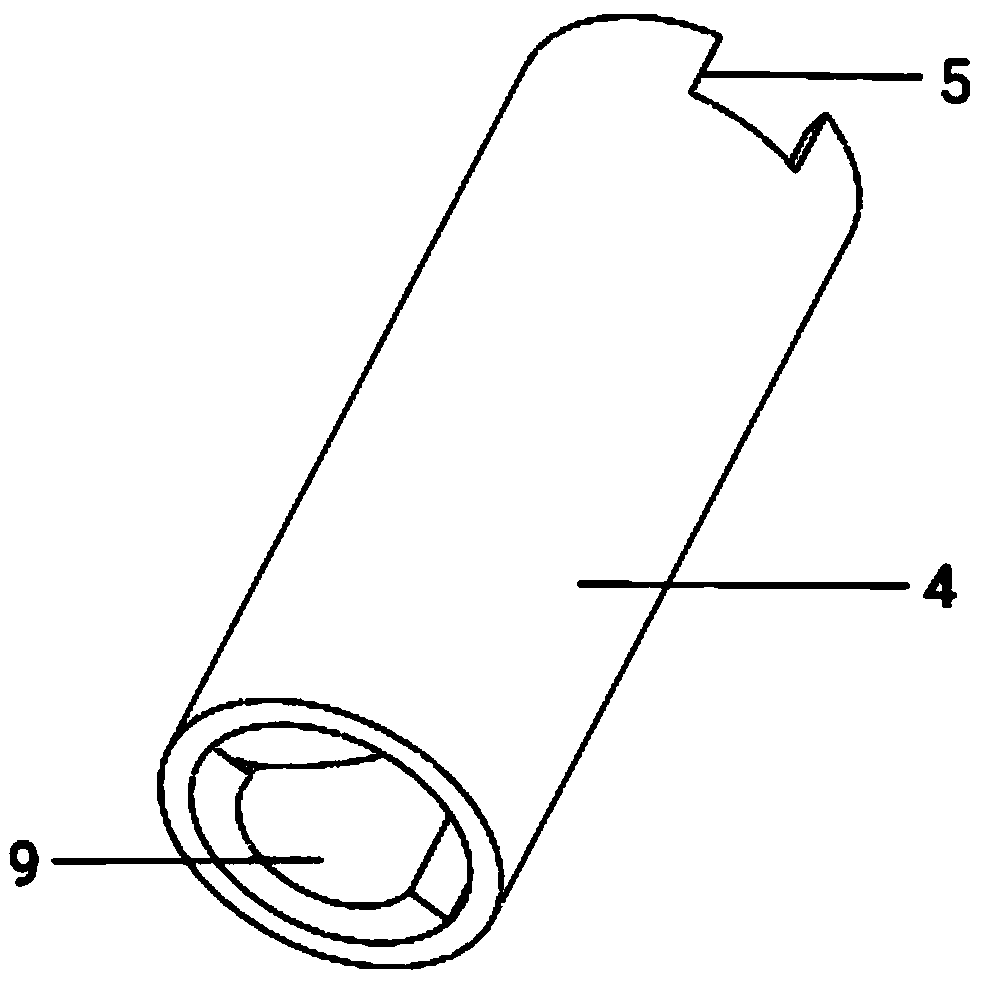

[0018] combine figure 1 , a self-lubricating ordinary hinge of the present invention, comprising two hinge pieces 2, each of the two hinge pieces 2 is fixedly connected to an outer rod 4, and an inner rod 10 is sleeved inside each of the two outer rods 4; The annular gap between the outer rod 4 at the upper end and the inner rod 10 is used as the first oil filling port, and the upper end of the outer rod 4 at the lower end is provided with a second oil filling port 5; the outer rod 4 is provided with a spiral boss 9 inside A push rod 7 is provided between the outer rod 4 and the inner rod 10; the lower end of the push rod 7 is supported on the boss 9, and the upper end is fixedly connected with an oil push ring 6; the oil push ring 6 is set on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com