Vacuum-pumping oil injecting device

An oil filling device and vacuuming technology, which is applied in the distribution device, special distribution device, liquid distribution, transportation or transfer device, etc., can solve the problems of breaker rod damage, oil pressure buffer cannot be injected quickly, etc., to achieve easy portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

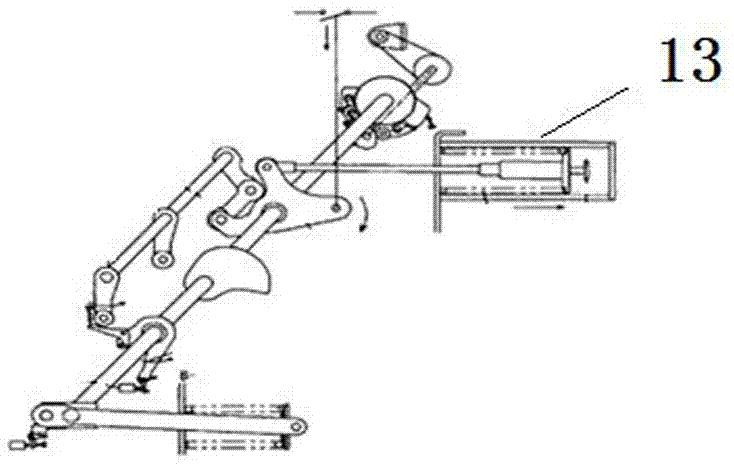

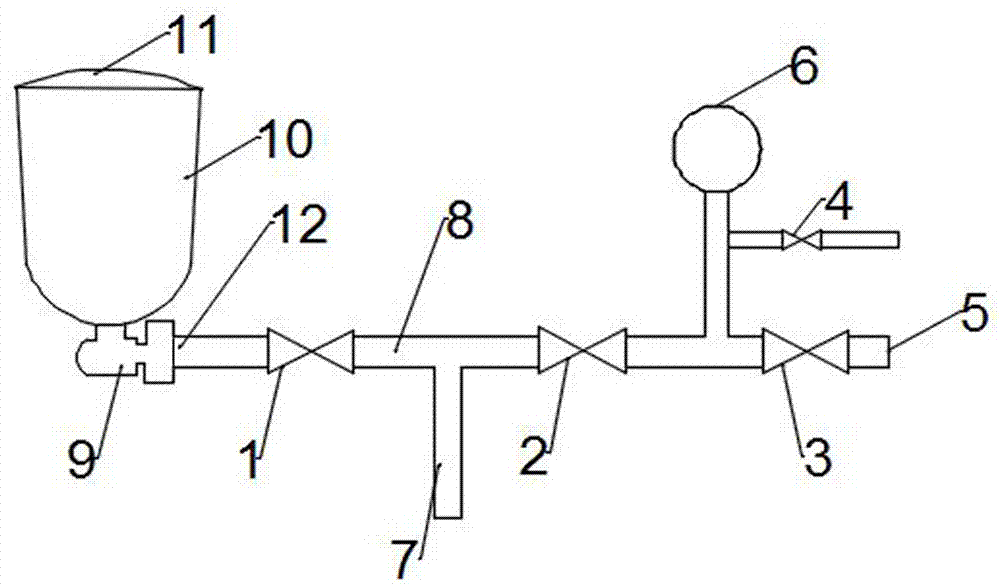

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

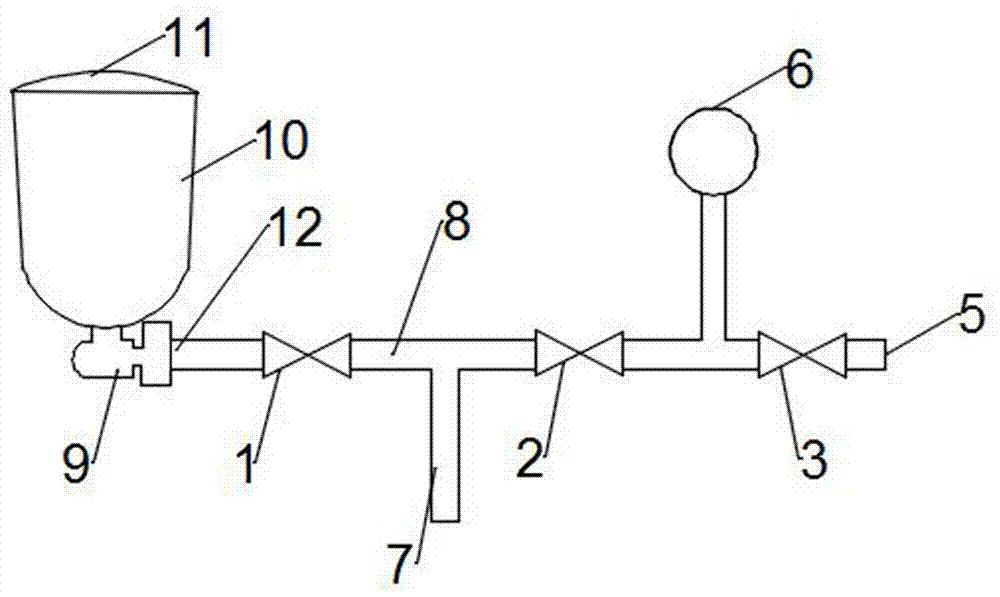

[0026] Specific embodiment one of the vacuum oiling device of the present invention, as figure 2 As shown, the vacuum oiling device includes a first stop valve 1, a second stop valve 2, a third stop valve 3, a pressure relief valve 4, a vacuum pump connection port 5, a vacuum gauge 6, an oil pressure buffer connection port 7, a straight pipe 8. Connecting piece 9, oil funnel 10 and oil funnel cover 11. In this embodiment, one end of the straight pipe 8 is an oil inlet 12, and the oil inlet 12 is connected with an oil injection device, and the oil injection device includes an oil funnel 10 and a connecting piece 9, and the connecting piece 9 is used to communicate the oil inlet and the oil funnel , The oil funnel is also provided with an oil funnel cover 11. The other end of the hand-held pipe fitting 1 is a vacuum pump connection port 5, and the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com