Indoor rock direct shear test device and method capable of providing constant normal stiffness

A technology of test device and test method, which is applied in the direction of applying stable shear force to test the strength of materials, and can solve the problems that the frictional resistance of the side reaction force device affects the test results, and the normal stiffness of the upper shear box is applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

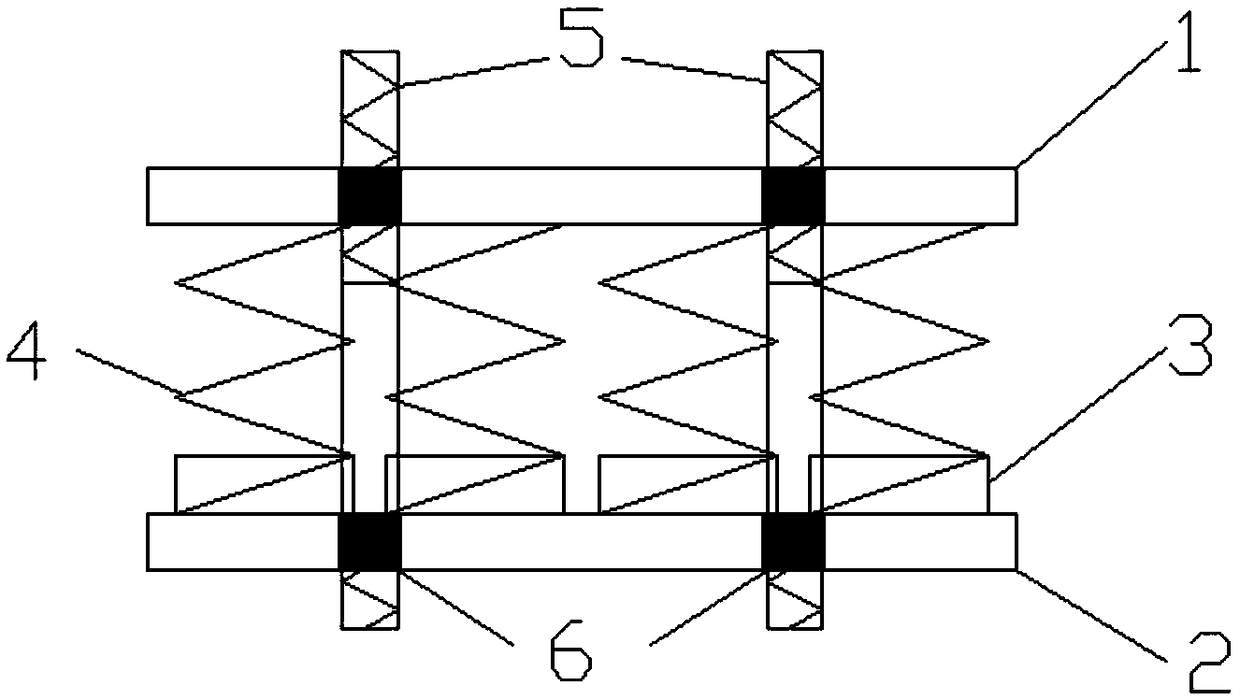

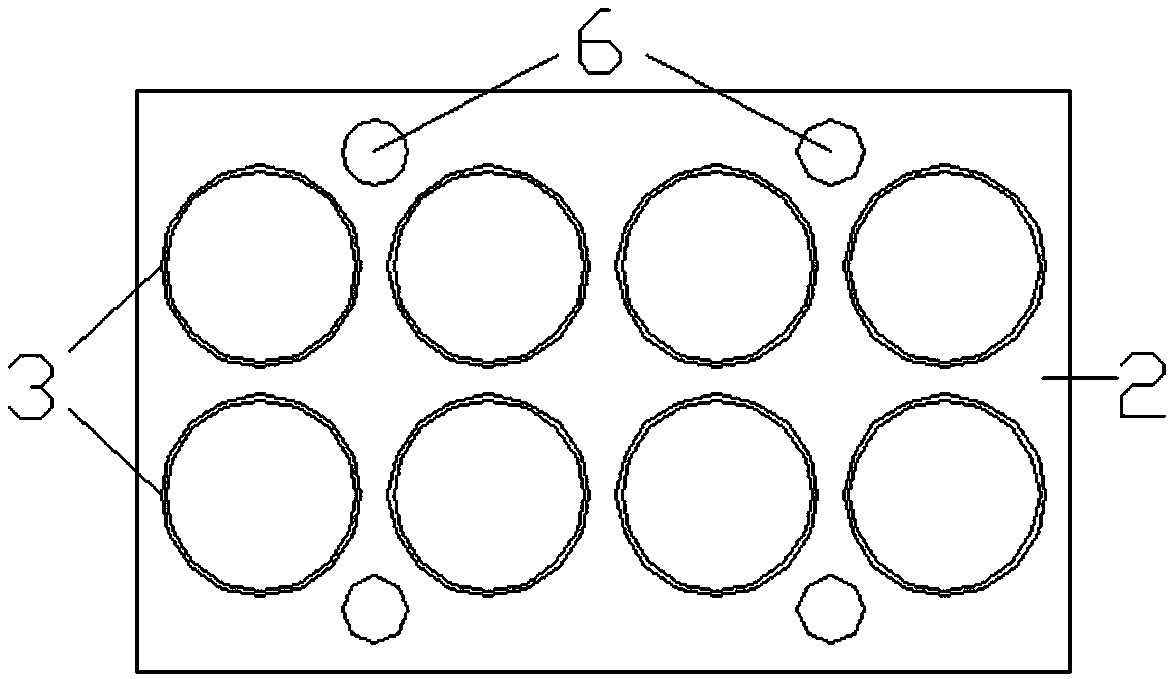

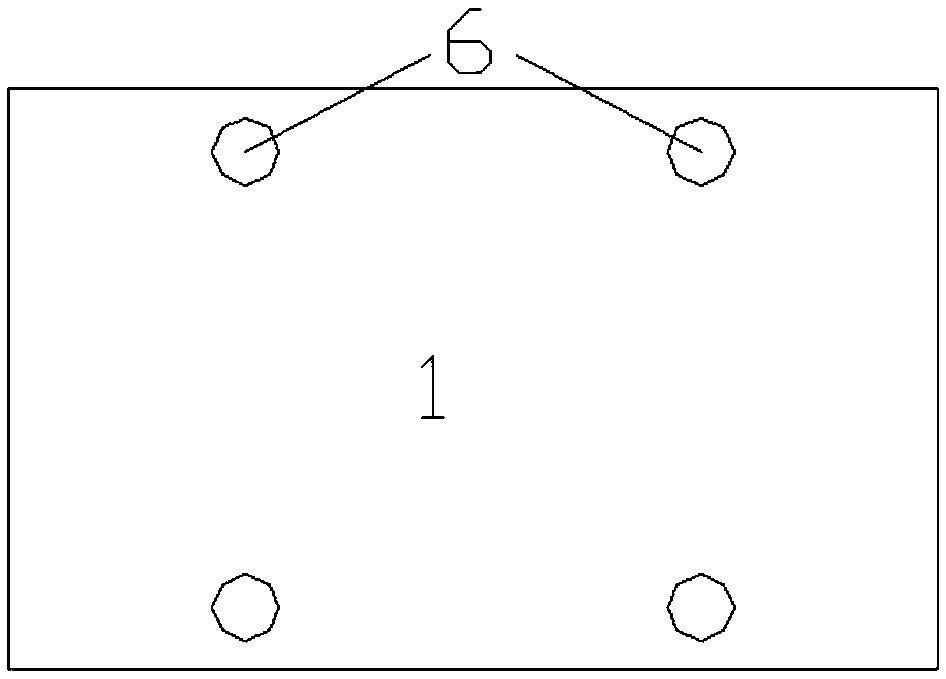

[0035] like Figure 1-8 The shown indoor rock direct shear test device that can provide constant normal stiffness includes a spring box and a counter force fixture. like figure 1 As shown, the upper base plate 1 of the spring box is a smooth steel plate with four through holes 6, and the lower base plate 2 is welded on one side with 8 evenly distributed thin-walled steel sleeves 3 with an inner diameter slightly larger than the spring diameter. There are four through holes 6 on it. The spring 4 is a spring with different rigidities manufactured according to different test requirements. like Figure 4 As shown, the screw rod 5 is a steel rod whose two ends are threaded regions and the middle section is a smooth region. The screw rod 5 passes through the upper and lower bottom plates and the bottom plate of the vertical loading system through the through hole 6, and both ends of the upper threaded area are fixed with nuts, such as Figure 8As shown, the spring box is connec...

Embodiment 2

[0038] Implementation of an indoor rock direct shear test method that can provide constant normal stiffness: connect the spring box system with the bottom plate of the vertical loading system through screws, and connect and fix the bottom plate of the reaction force fixture with the direct shear test device through bolts . That is, the assembly of the indoor rock direct shear instrument that can provide constant normal stiffness is completed.

[0039] Spread butter on the roller surface of the horizontal displacement platform of the direct shear instrument and the top roller surface of the counterforce fixing device to further reduce its frictional resistance. The lower shear box is placed on the roller of the horizontal displacement platform, and the rock specimen is placed in it, and the upper shear box is covered on it, and the side wall of the upper shear box is in direct contact with the top roller of the reaction force fixture. Start the loading system, control the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com