Method for determining shear strength of chemically polluted soil and special full-automatic direct shear apparatus

A shear strength and chemical pollution technology, applied in the application of stable shear force to test the strength of materials, preparation of samples for testing, etc., can solve the problems of parameter deviation, measurement result deviation, limited guiding significance, etc. Small fluctuation, uniform corrosion distribution, and the effect of reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

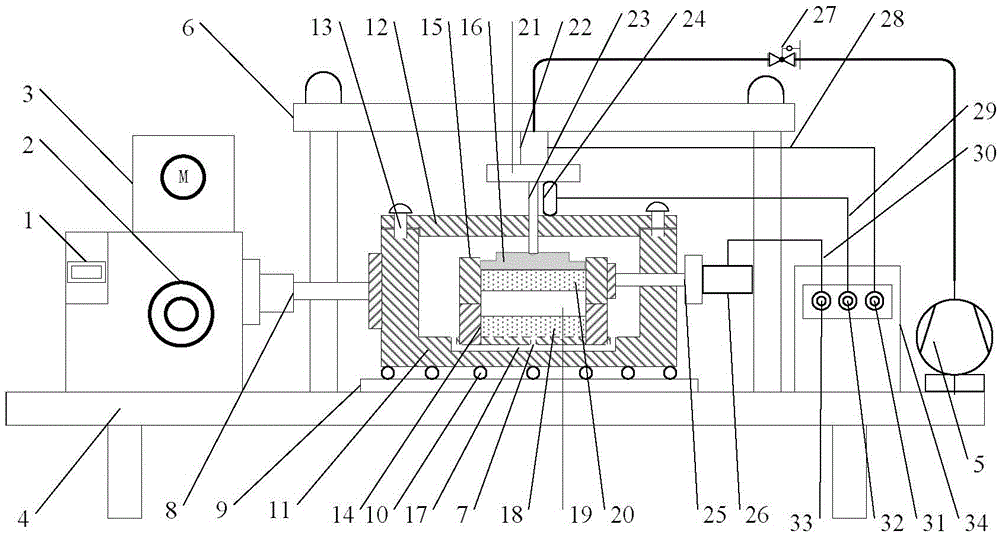

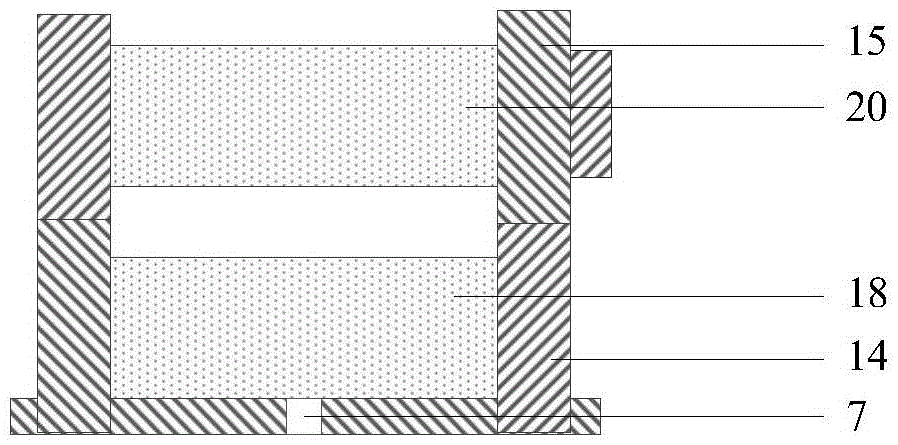

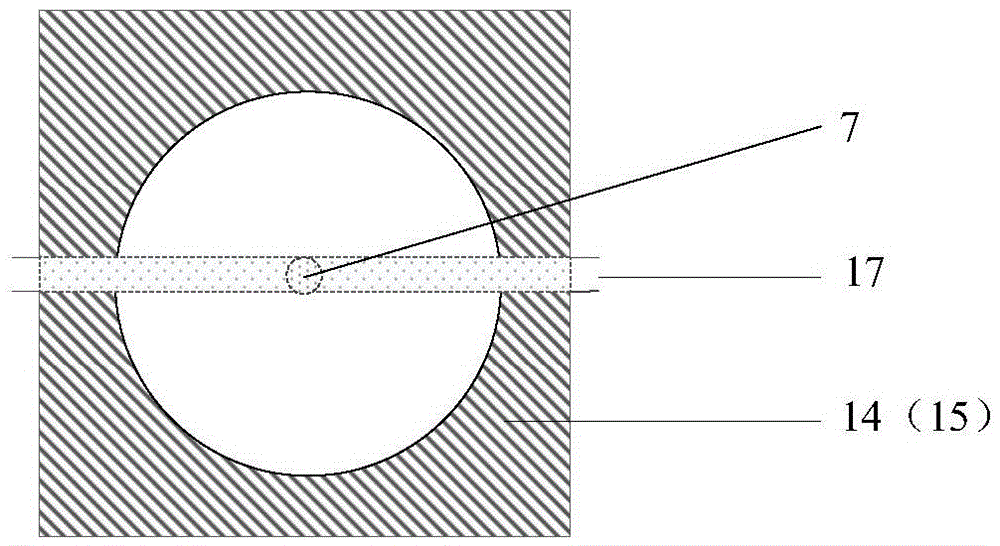

[0027] like figure 1 , figure 2 As shown, the automatic direct shear instrument of the present invention adds a chemical corrosion device on the basis of conventional direct shear test instruments. That is, the fully automatic direct shear instrument of the present invention includes a horizontal platform 4, a horizontal loading device, a vertical loading device, a data measurement and control device arranged on the horizontal platform 4, a shear box, and a chemical corrosion device. The chemical etching device is composed of a container tank 11 and a container cover 12. The container tank is slidably connected to the horizontal platform 4 through the horizontal ball guide rail 9 and the ball 10. The bottom is provided with an engraved groove 17, and the center of the bottom of the lower shear box 14 is provided with a The infiltration hole 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com