Automatic optical inspection equipment problem point secondary calibration method

An inspection equipment, automatic optical technology, applied in image data processing, instruments, calculations, etc., can solve problems such as failure to deal with problem points, and release of problem points if they fail to meet the standard, to eliminate the possibility and reduce the missed detection rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention discloses a method for secondary verification of problem points of automatic optical inspection equipment. The specific implementation modes of the invention will be further described below in combination with preferred embodiments.

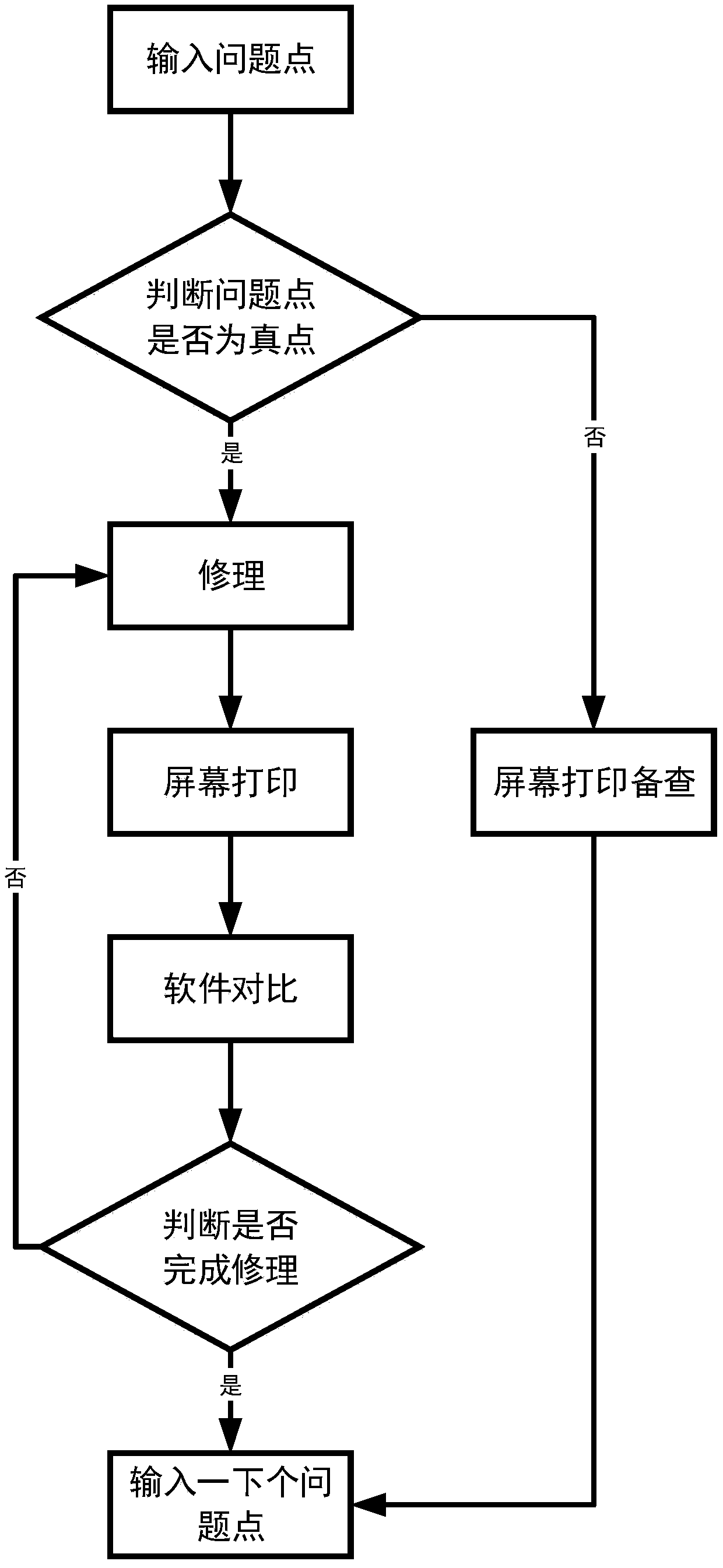

[0022] see attached figure 1 , figure 1 It shows the relevant process of the secondary verification method for the problem point of the automatic optical inspection equipment.

[0023] Preferably, the method for secondary verification of problem points of automatic optical inspection equipment includes the following steps:

[0024] Step S1: Input the problem point, and judge whether the problem point entered this time is true according to the preset comparison principle, if it is judged to be true, then execute step S2, otherwise, perform screen printing (for future reference) and repeat step S1;

[0025] Step S2: Repair the problem points judged as true in step S1 or the problem points judged to be unfinished in step S3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com