A stator structure of a flat wire motor

A technology of stator structure and flat wire, which is applied in the field of flat wire motor stator structure, can solve problems such as damage to flat copper wire insulation and copper wire performance, high technical difficulty in manufacturing process, and high bending difficulty, so as to avoid bending process, Improved ease of production and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The concrete implementation method of the present invention is as follows:

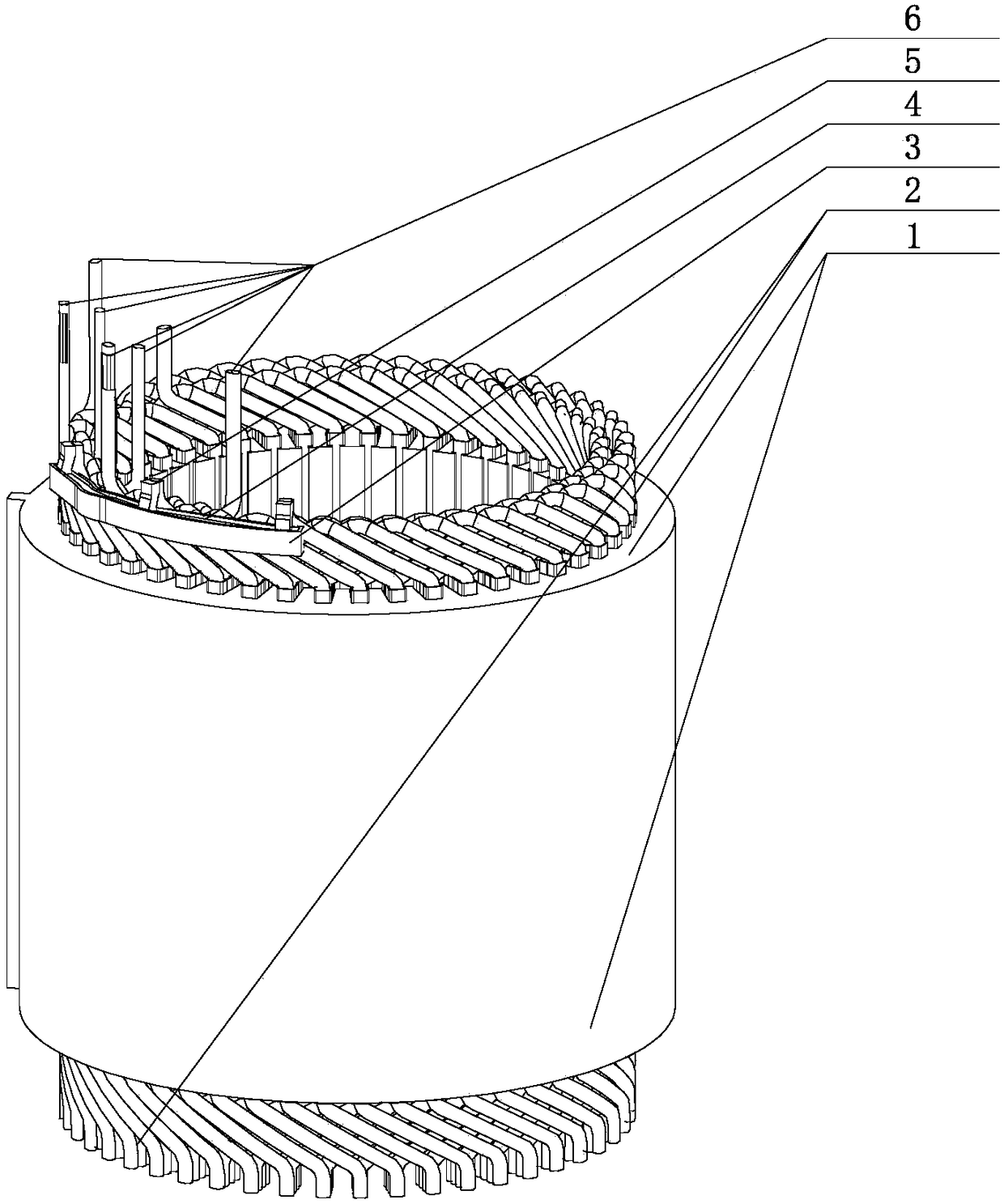

[0018] like Figure 1-3 As shown, the stator structure of a flat wire motor is composed of a stator core 1 made of magnetic steel sheets, a stator winding 2 wound by flat copper wires, copper outlet terminals 6 and bus bars 3, and the stator winding is made of flat copper The wire is wound, and the cross-sectional area of the copper wire is determined by the rated power and current of the motor. The bus bar 6 is fixed at the solder joint of the winding, and is electrically connected with the solder joint by soldering.

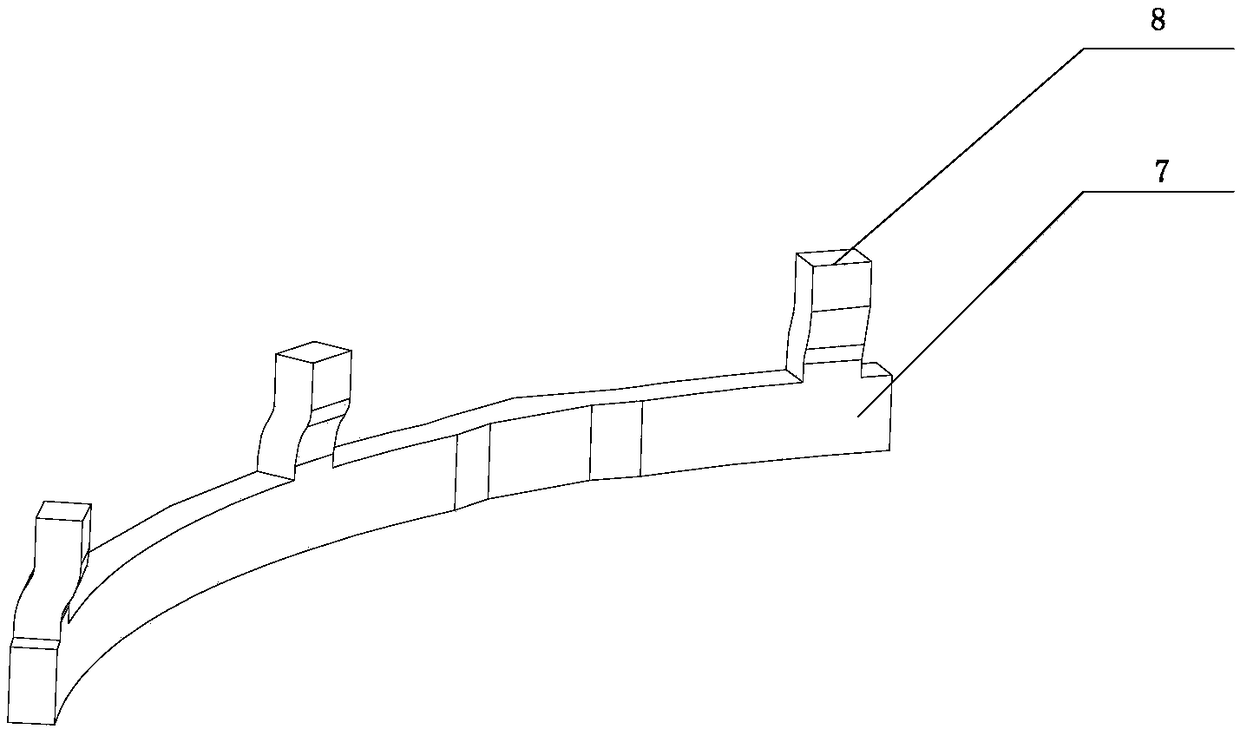

[0019] The bus bar 5 is composed of an insulating base 3 and a copper bar 4 , the insulating base 3 is made of polyethylene, the copper bar 4 is made of brass, and the copper bar 4 is inserted inside the insulating base 3 .

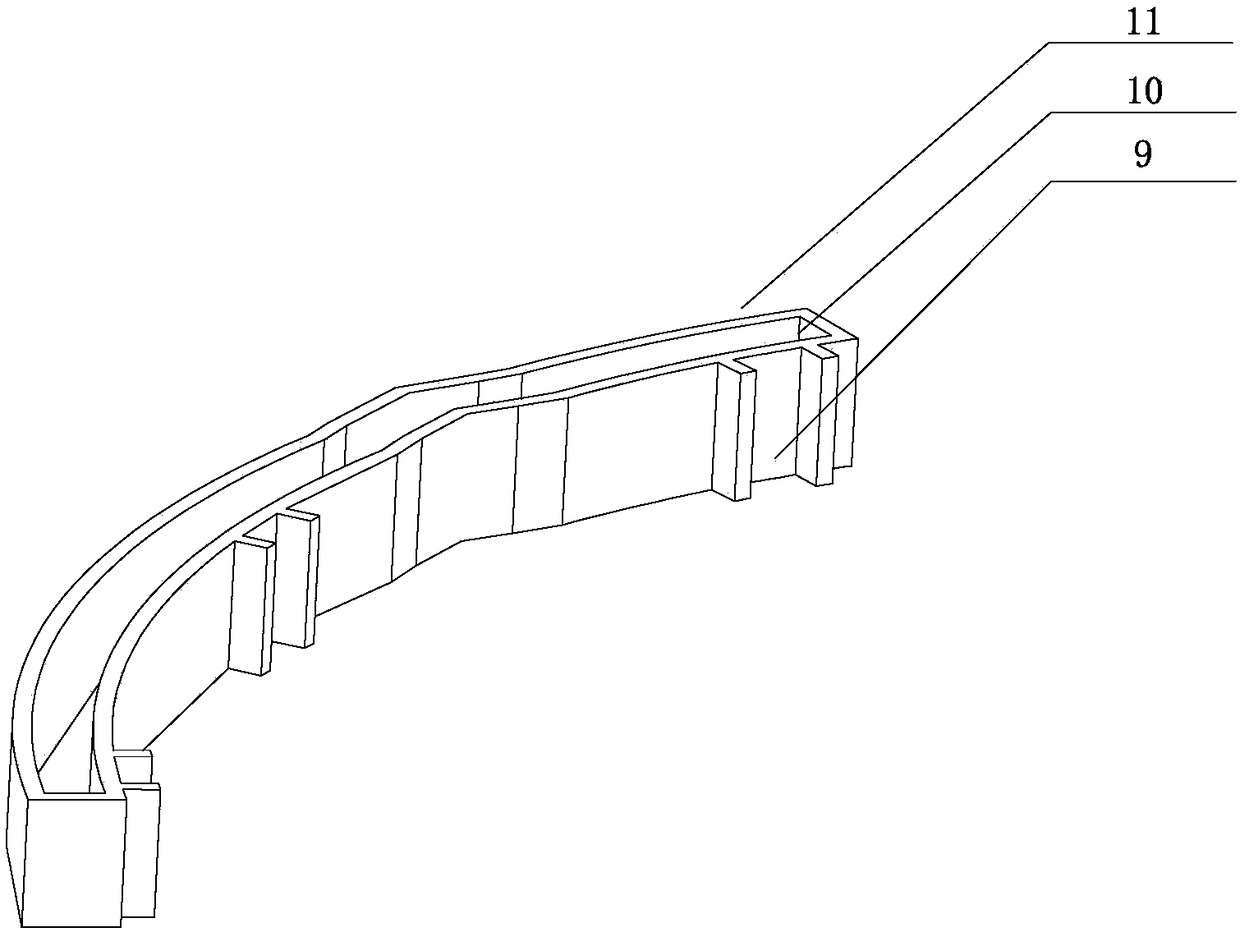

[0020] The insulating base 3 has an arc-shaped groove structure as a whole, and is composed of an insulating base shell 11, an insulating base groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com