Microphone and manufacturing method thereof

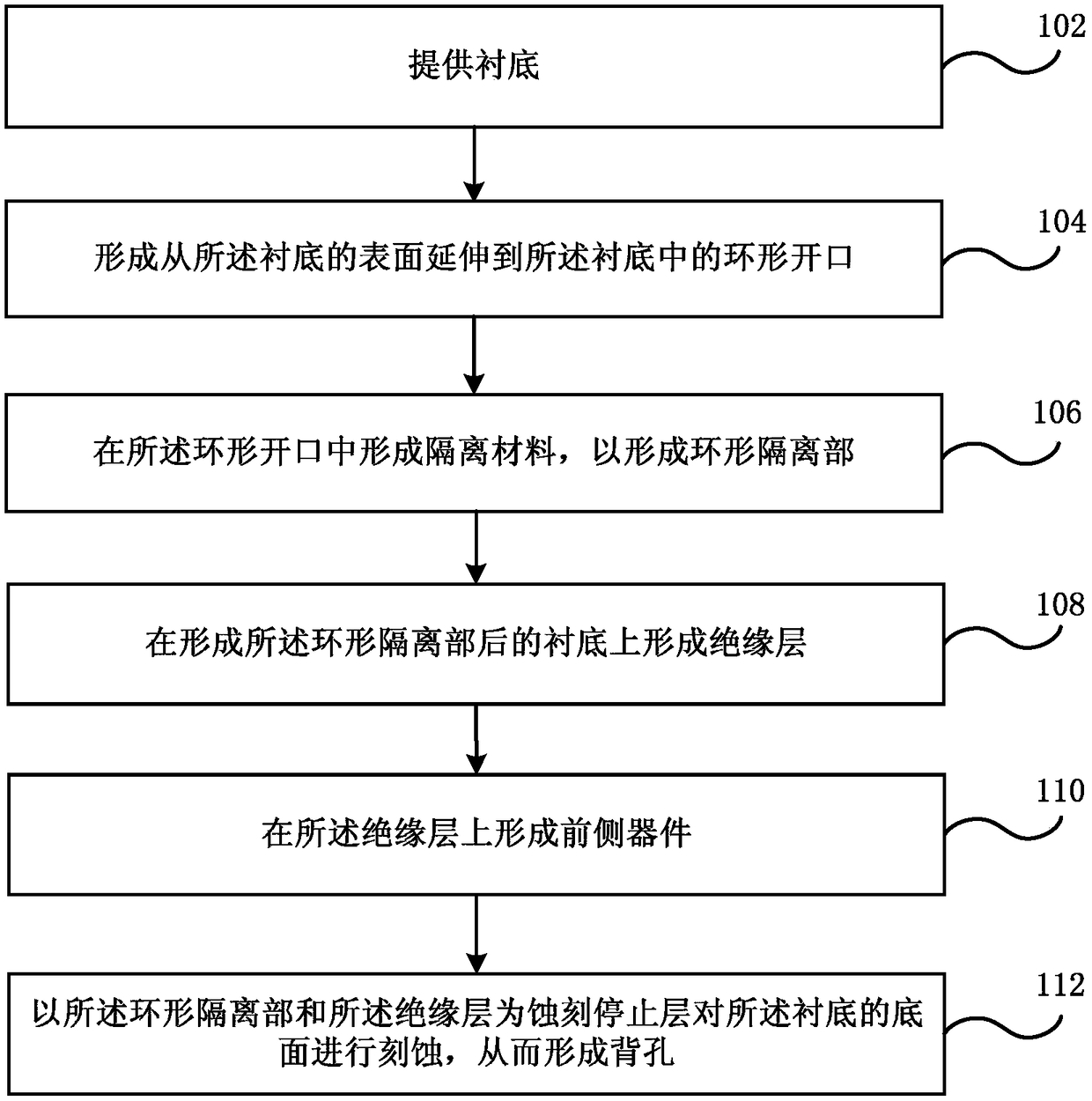

一种制造方法、麦克风的技术,应用在半导体静电换能器、扩音器、静电换能器传声器等方向,能够解决不满足设计要求、影响麦克风信噪比等性能等问题,达到改善容易损坏、提高性能的一致性、提升性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

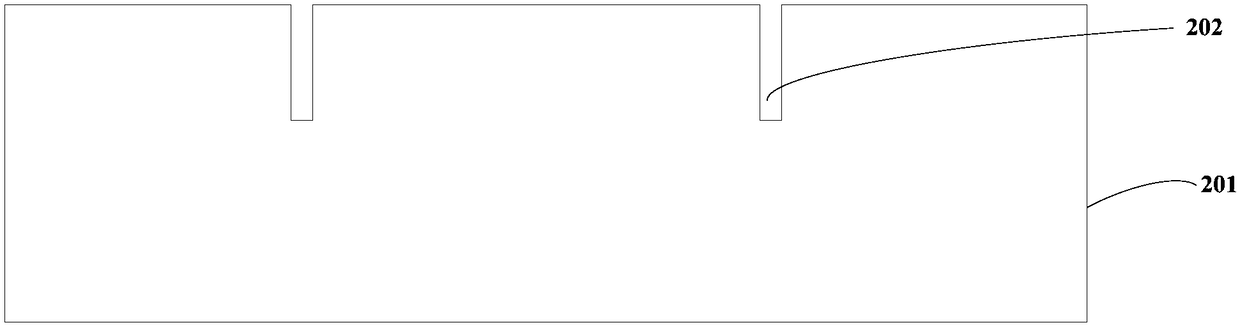

[0036] Various exemplary embodiments of the present application will now be described in detail with reference to the accompanying drawings. It should be understood that the relative arrangements of components and steps, numerical expressions and values set forth in these embodiments should not be construed as limiting the scope of the present application unless specifically stated otherwise.

[0037] In addition, it should be understood that, for the convenience of description, the dimensions of the various components shown in the drawings are not necessarily drawn according to the actual scale relationship, for example, the thickness or width of some layers may be exaggerated relative to other layers.

[0038] The following description of the exemplary embodiments is illustrative only and is not intended to limit the application, its application or uses in any way.

[0039] Techniques, methods and devices known to those of ordinary skill in the relevant art may not be disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com