A method for making silk suitable for thin cigarette

A technology for thin and shredded tobacco, which is applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of no length-controlling processing procedure of shredded tobacco, low degree of homogenization of the structure and shape of shredded tobacco, inability to achieve homogenization of cigarette shredding, and the like, Achieve the effect of reducing the cost of raw material formulations, improving the stability of physical indicators, and meeting the needs of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

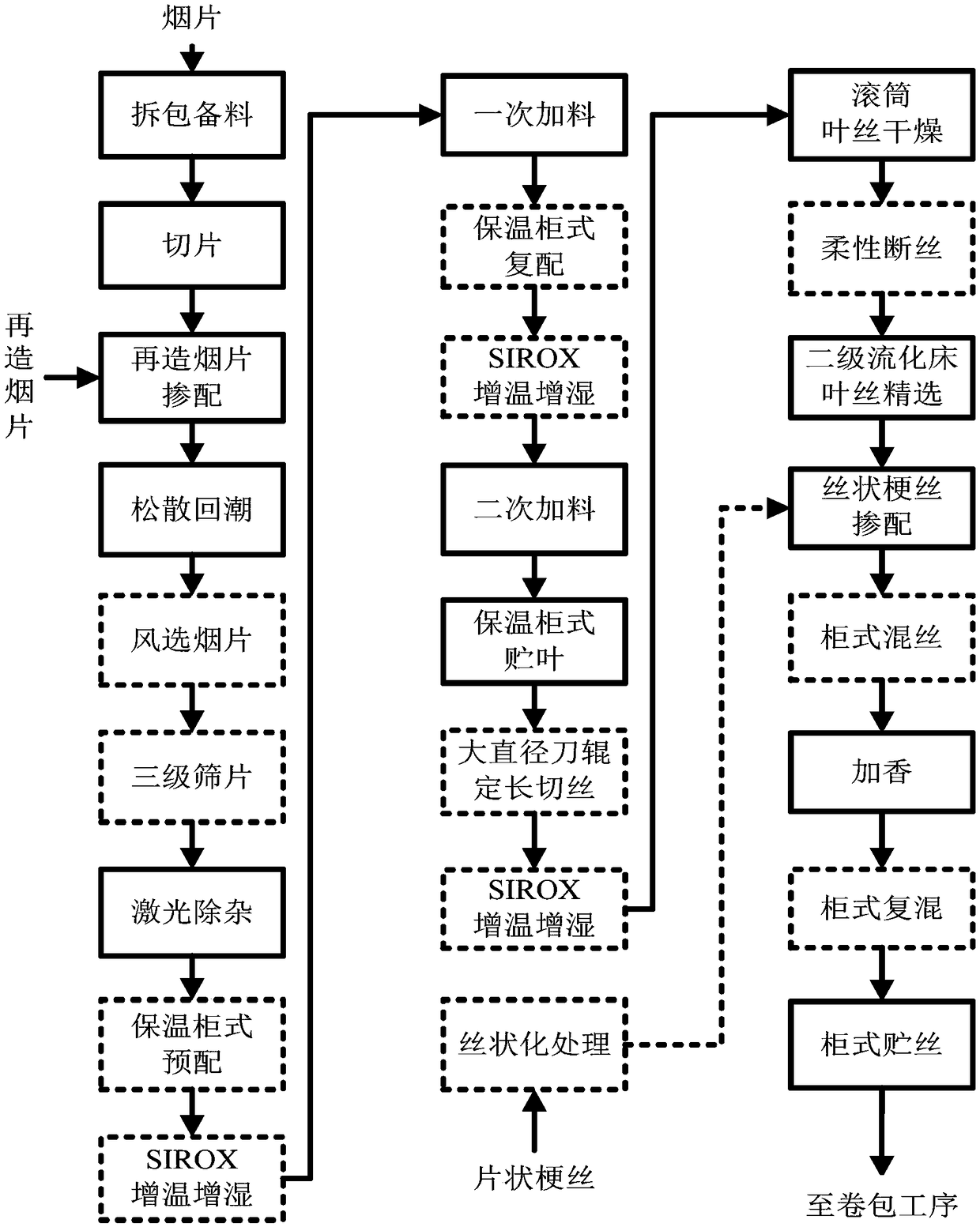

[0041] A specific process suitable for thin cigarette shreds is: unpacking and preparing materials, slicing, blending of reconstituted tobacco sheets, loosening and regaining moisture, winnowing tobacco sheets, three-stage sieving, laser removal of impurities, warming cabinet type pre-blending, the first SIROX heating and humidification, primary feeding, insulation cabinet compounding, second SIROX heating and humidification, secondary feeding, insulation cabinet storage, knife roller cut to length, third SIROX heating and humidification, roller leaf Silk drying, flexible broken silk, second-stage fluidized bed leaf silk selection, silky stalk blending, cabinet blending, flavoring, cabinet compounding, cabinet storage, and wrapping.

[0042] Preferably, the step of unpacking and preparing materials is to unpack the box body of the boxed compressed laminae by an unpacking machine, and recover the box skin.

[0043] Preferably, the slicing step is to use a slicing machine to cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com