Spine protection schoolbag for rectification by gas flow bulging based on fluid engineering mechanics

A technology of gas flow and fluid engineering, which is applied in small bags, medical science, orthopedic corsets, etc., can solve the problems of reduced strain capacity, inability to make the device protect the spine, and the spongy body is prone to corruption, so as to protect the shoulders Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

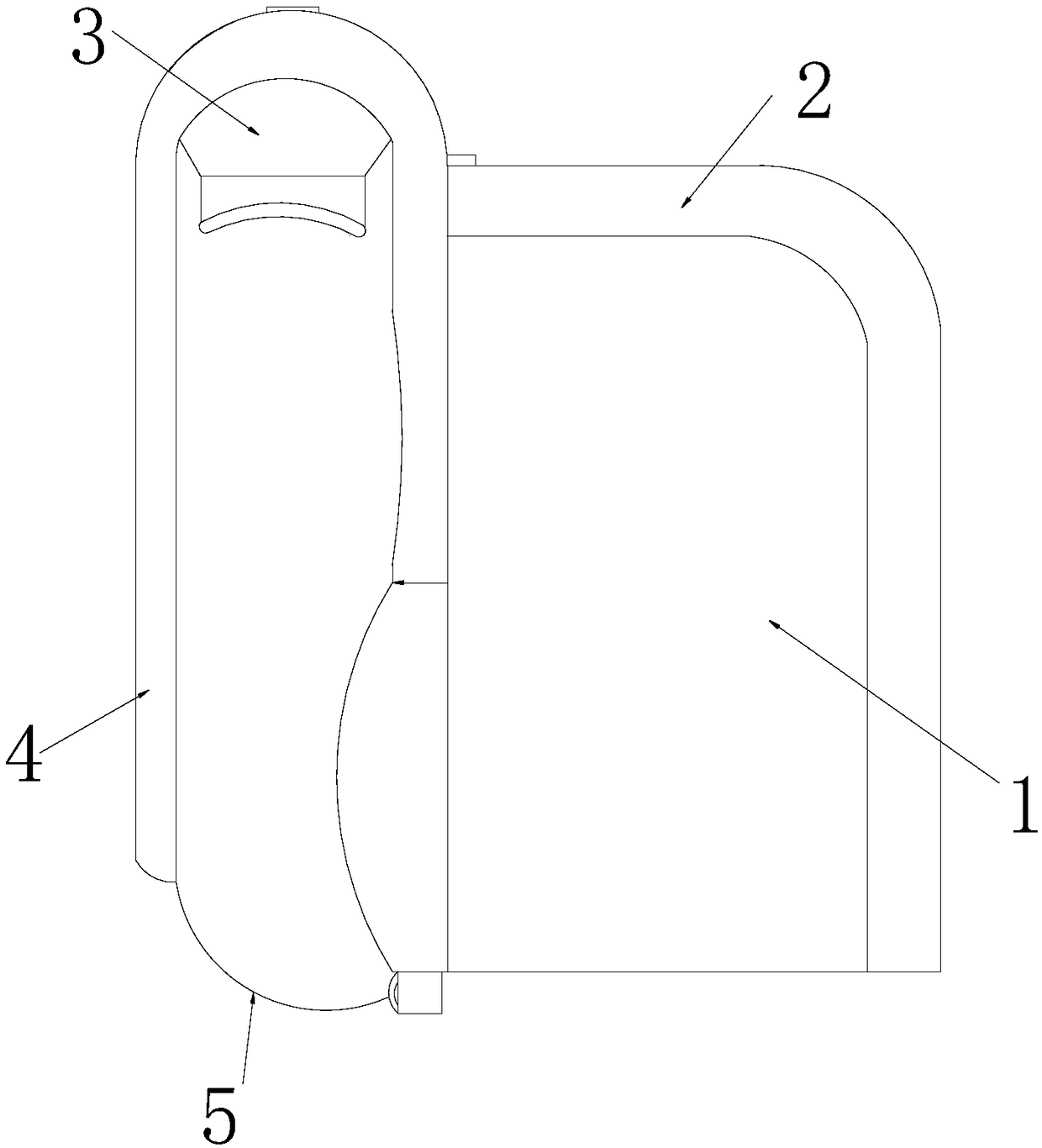

[0022] see figure 1 , the present invention provides a ridge protection schoolbag based on fluid engineering mechanics through gas flow bulge correction, its structure includes: accommodating bag body 1, protective plate 2, gas correction device 3, strap 4, adjustment belt 5, said protective plate 2 is located The upper end surface of the accommodation bag 1 is movably connected with the accommodation bag 1, the gas correcting device 3 is arranged on the left end surface of the accommodation bag 1 and is an integral structure with the accommodation bag 1, and the strap 4 is arranged on the The lower end surface of the gas correction device 3 is fixedly connected with the gas correction device 3 to form an integrated structure. The adjustment belt 5 is located at the lower end surface of the strap 4 and is movably connected with the strap 4. The protective plate 2 is provided with a Buckle frame for sealing.

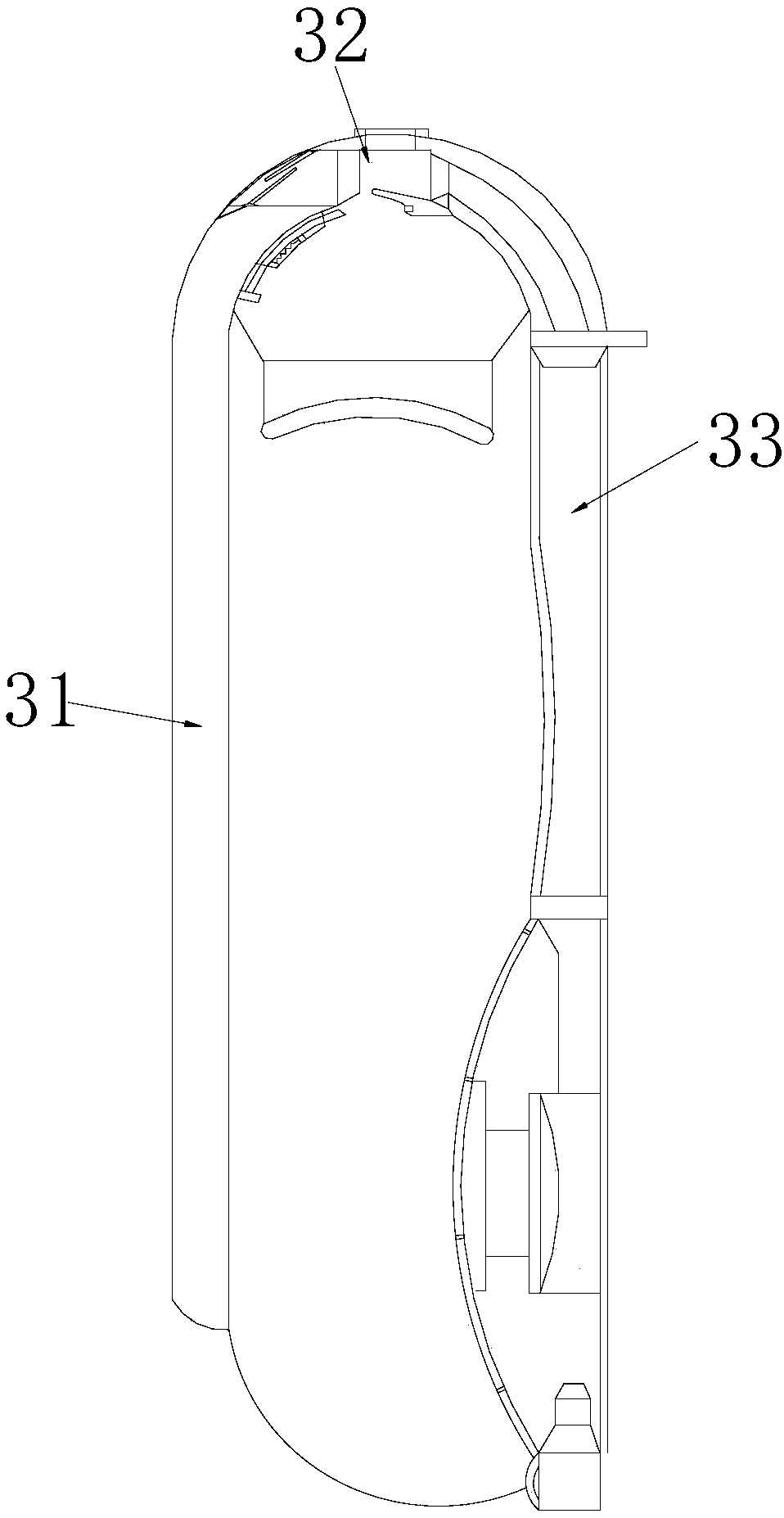

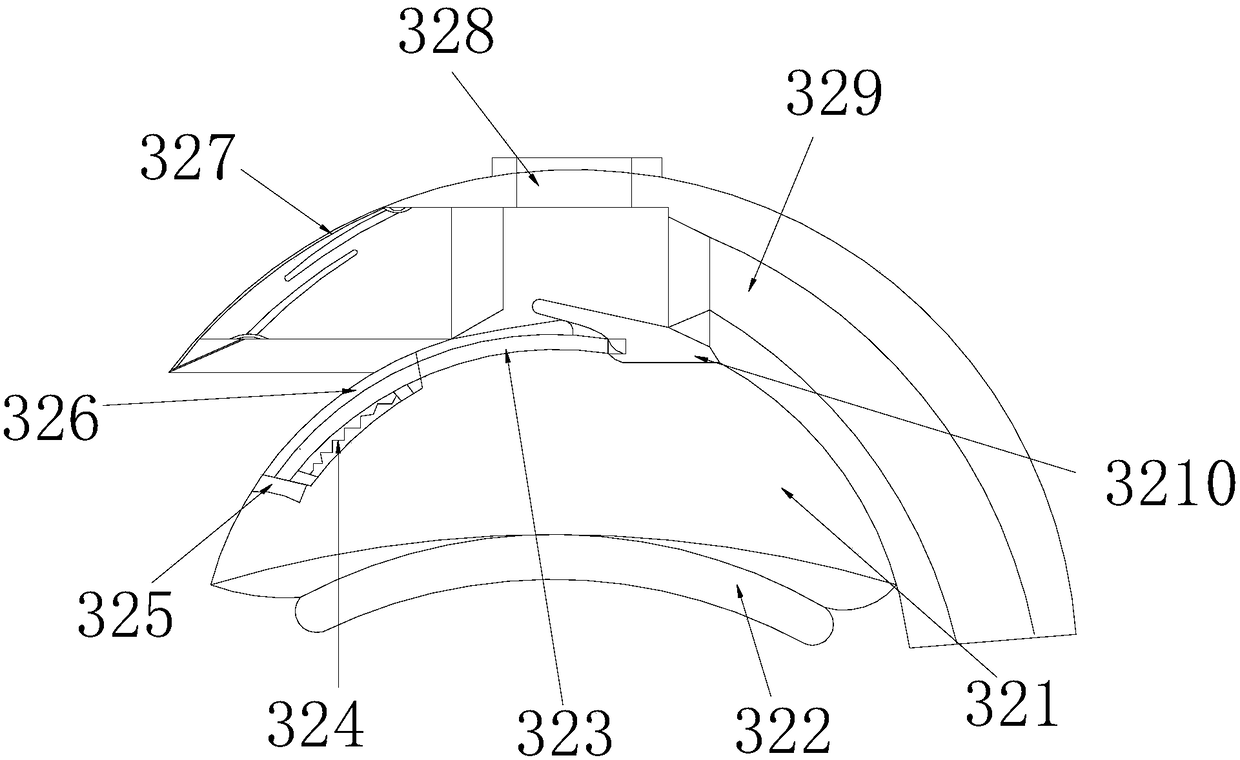

[0023] see figure 2 , the present invention provides a ridge prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com