Cleaning head for surface cleaning device

A technology of surface cleaning device and cleaning head, which is applied to cleaning equipment, applications, household appliances, etc. It can solve the problems of reducing the efficiency of floor brush inhaling dirty liquid, secondary pollution of the surface to be cleaned, and occupying space, so as to achieve better anti-backflow effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

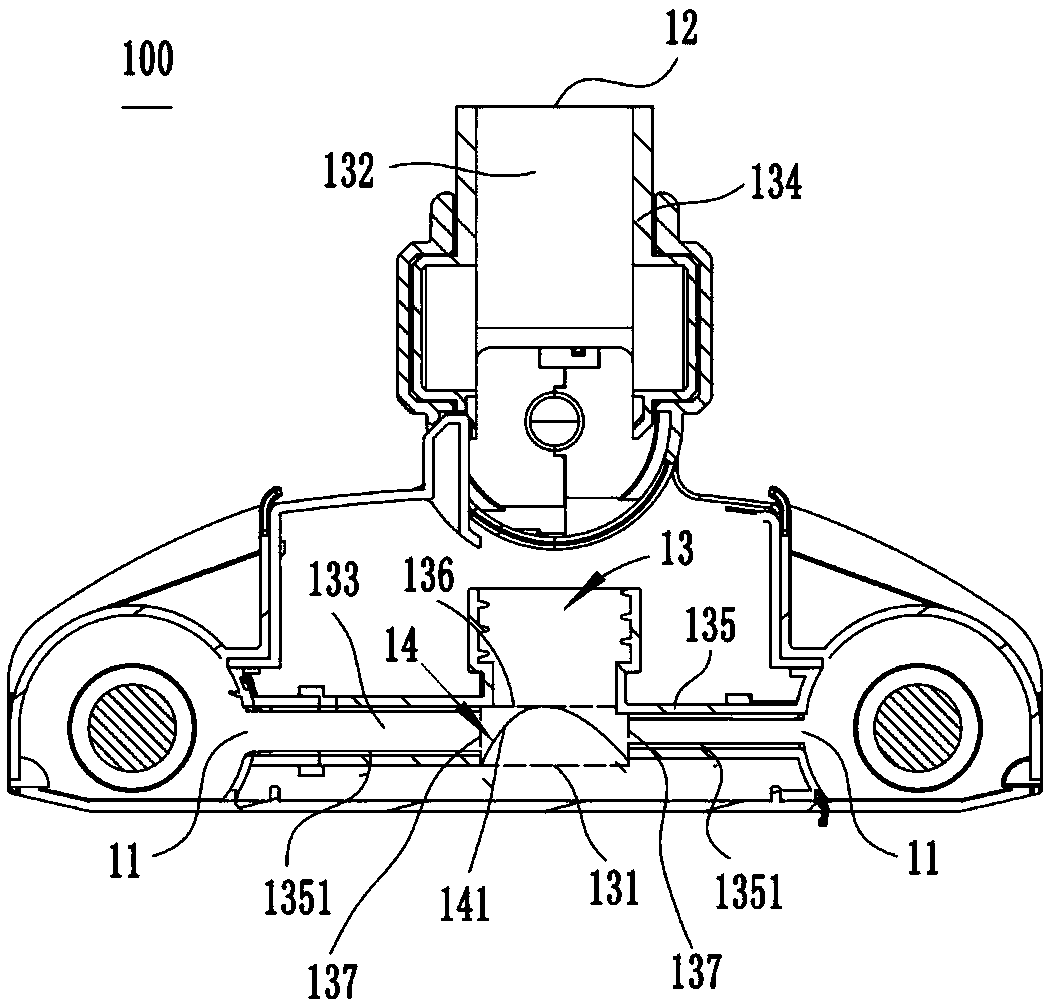

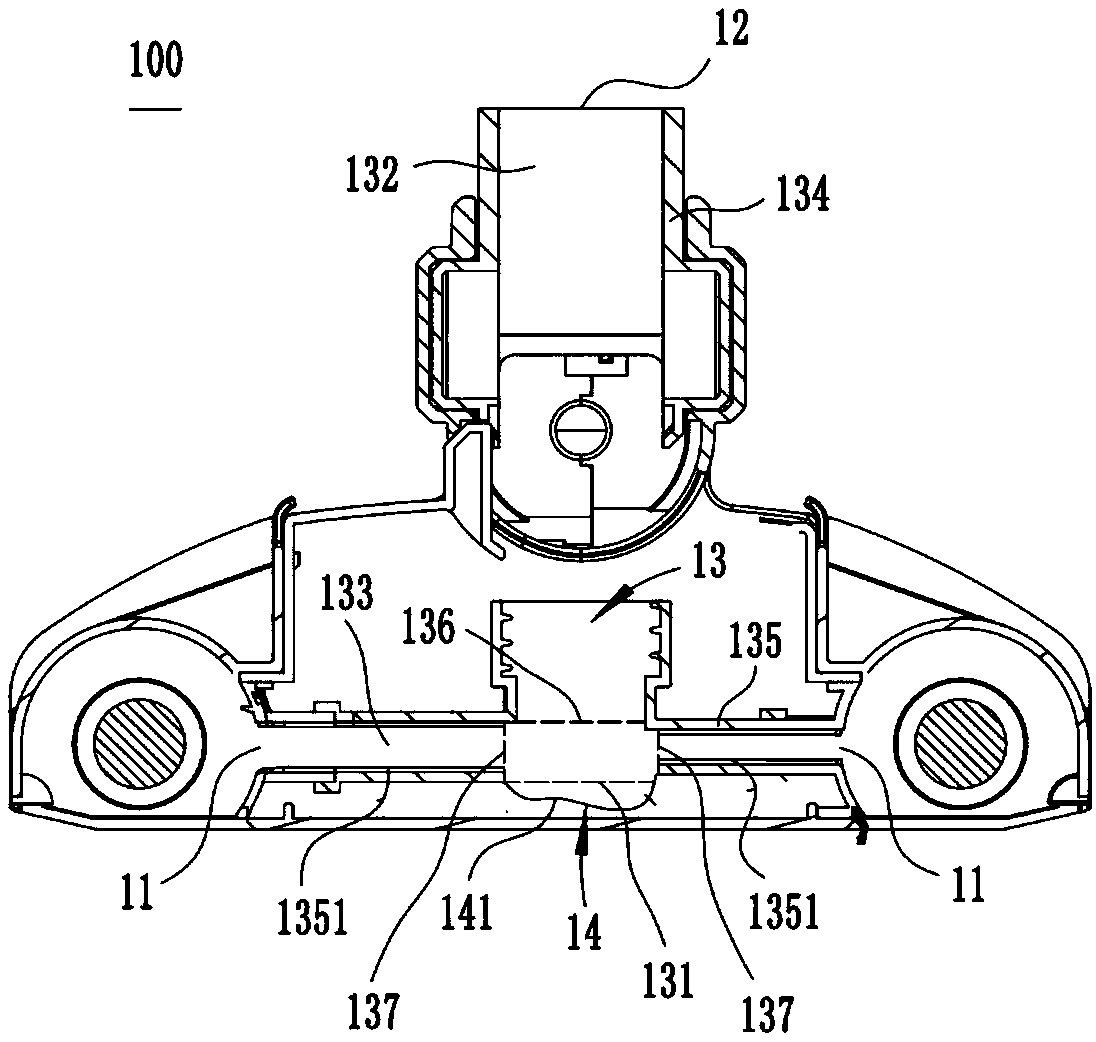

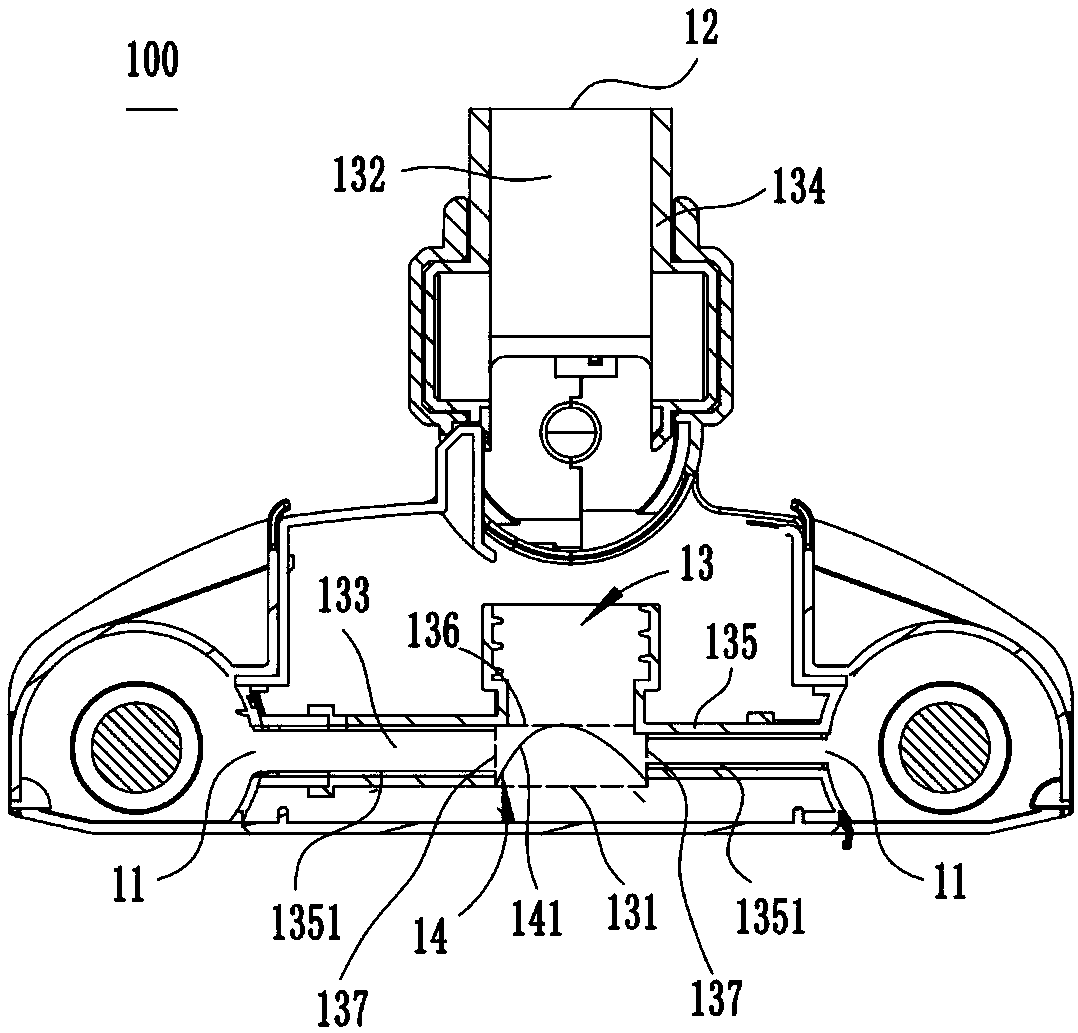

[0030] The first embodiment: the relationship between the upper and lower positions described in this embodiment and the attached figure 1 Corresponds to the up and down positional relationship of the cleaning head shown in ; figure 1 Corresponds to the left direction of the cleaning head shown in figure 1 Corresponds to the right-hand orientation of the cleaning head shown in ; figure 1 Corresponds to the up and down direction of the cleaning head shown in figure 1 Corresponds to the orientation of the horizontal plane in which the cleaning head is shown in .

[0031] According to attached figure 1 As shown, the cleaning head 100 includes a cleaning head body, the bottom front side and the bottom rear side of the cleaning head body are respectively provided with a suction port 11, the top of the cleaning head body is provided with an output port 12, and the inside of the cleaning head body is provided with a fluid channel 13 and The dirty liquid returns to the collecting ...

no. 2 example

[0043] The second embodiment: the relationship between the upper and lower positions described in this embodiment and the attached Figure 4 Corresponds to the upper and lower positional relationship of the fluid channels shown in .

[0044] According to attached Figure 4 And attached Figure 5 As shown, the fluid channel 23 is provided with a return port 231 with its mouth facing downward, and the return port 231 is located at the lower side of the output port 22 . The fluid channel 23 includes an upstream sub-channel 232 located upstream of the return port 231 and a downstream sub-channel 233 located downstream of the return port 231. The upstream sub-channel 232 includes an end opening 236 near the return port 231, and the end opening 236 is up and down with the return port 231. relatively accurate. Specifically, the upstream channel 232 includes a vertical pipe section 234 , and the end opening 236 is located at the lowermost end of the vertical pipe section 234 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com